Have 75 SS o-ring acorn nuts for ZF. 8 mm x 1.25 thread. Viton o-rings. Made by Zago. $3.45 each (my cost) plus shipping.

Replies sorted oldest to newest

Your acorn nuts with integrated o-ring are top shelf. But if you use a washer in front of the nut then there is still a potential for an oil leak. Is there a washer with a seal that pairs with this? I have used silicon to seal the nuts and washers on the back plate of the ZF. It works well but it is messy and I used about a half roll of paper towels in the process.

I'm not using a washer. There's no washer pair. I've tried washers with seals on the inner diameter, square o-rings, all to no avail. I think these are the best solution. I'm using minimal torque to hopefully prevent damage to the casing. I'm sure you've experimented as well.

I pulled the washer with bonded rubber/neoprene off of some metal roof self drilling screws and installed them on my bottom cover bolts.

most are still not leaking, a couple have a little bit of weeping.

combined with the acorn nuts this might be even better?

Larry

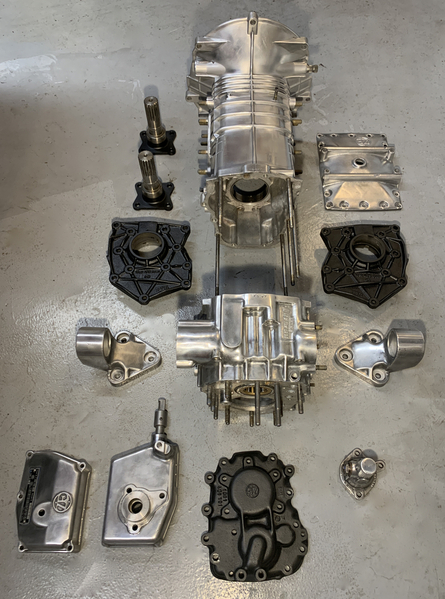

Attachments

Hmmm....possibly.

"I'm using minimal torque to hopefully prevent damage to the casing."

I am a little concerned about this. The back cover is good quality steel and is intended to be torqued to spec. I don't think you can damage the back cover by omitting the washers. Six of the studs are long and go all the way through the rear aluminum case. Under torquing could allow the back cover and/or rear case to shift or flex.

Attachments

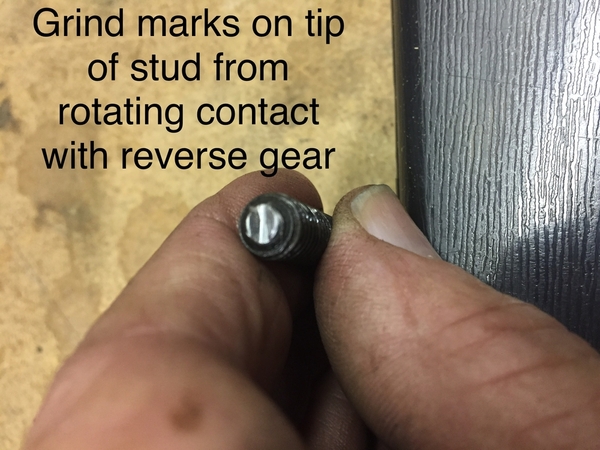

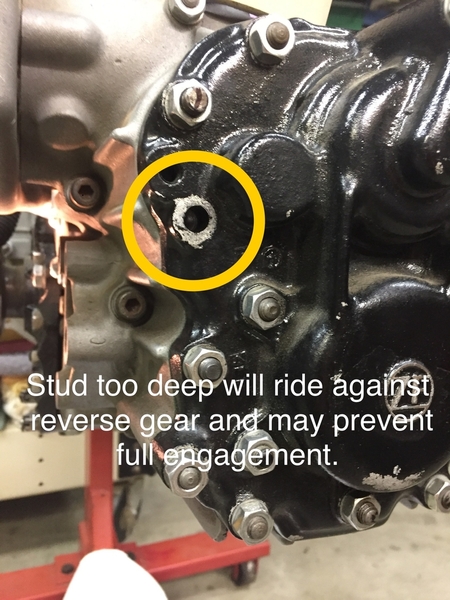

Since we are talking about the rear cover I will once again share what I learned regarding installing the rear studs and acorn nuts.

when I received my ZF from the vendor who upgraded to 0.620 fifth gear, I could not get the ZF to stay in reverse.

called the vendor who basically was no help at all. I had checked for the back up switch interference and had completely removed all linkage and was shifting using vice grip pliers. I knew the problem was internal to the ZF

What I eventually learned from a couple of fellow owners is that there is one stud that can screw so far through the back cover as to actually block the sliding movement of the reverse gear. Sure enough, upon removal I could see the grinding marks on the back of the stud.

just getting this out into the collective memory again.

Larry

Attachments

Interesting you bring that up. When I got mine back from RBT that stud was double nutted. I may have known this back then but its a good reminder.

@stevebuchanan posted:"I'm using minimal torque to hopefully prevent damage to the casing."

I am a little concerned about this. The back cover is good quality steel and is intended to be torqued to spec. I don't think you can damage the back cover by omitting the washers. Six of the studs are long and go all the way through the rear aluminum case. Under torquing could allow the back cover and/or rear case to shift or flex.

Steve,

Thanks for the heads up. I'll re-evaluate this for the back cover.

Steve,

Do you now the torque spec off hand?

10.8 lbs ft to 14.5 lbs ft.

Will be posting these on e-bay soon,

These are now on e-bay. Item # 115530043242

Bump. Only 19 remaining.

PM sent.

C. Engles

And responded to.

Any left?

PM me if so!

Thanks!

Rocky,

Sorry, no. Minimum order from manufacturer was 100.

@marlinjack posted:...You guys amaze Me how you over-think and complicate a simple matter.

DO This! The Stud Can ONLY Leak Around the Threads, inside of the clearance to the Plate!! First install a 'Thin' O-Ring (NOT Too Thin) over the Stud, Just slightly smaller than the stud and Snug it down to 'Bottom' it. Then Install a 'Common' Washer, NO Rubber on it...SS would be nice Or a 'Grade-8', Then...Torque-On the Acorn/O-ring, Nut! The Thin O-Ring WILL Crush-in between the threads and the Plate, if good quality, NO Seeping!! I've done this more times than I have fingers and toes. The Fact Is with the First O-Ring sealing the Stud...you don't even need a Second O-Ring on the Nut!! Think about THAT for One Minute! Sorry Husker.

...and I'll stake My reputation here...NEVER go Without a Washer!! Under EVERY Bolt-Head and Nut, Always Use a Washer! Or You'll Learn the Reasons Why!!

MJ

Tried. Failed.

And, yes, I did think about this. Working in the nuclear industry I know a think or two about preventing leaks,.

...I Think You DO Know...and these O-ring Nuts are GREAT!! I still think a good 'Piloted Spot-Face', on each bore, would help prevent any Seeping. Clean and Trued. It's the Scratches and Gouges, that cannot be Sealed.

MJ

@marlinjack posted:...I Think You DO Know...and these O-ring Nuts are GREAT!! I still think a good 'Piloted Spot-Face', on each bore, would help prevent any Seeping. Clean and Trued. It's the Scratches and Gouges, that cannot be Sealed.

MJ

Agreed.