just want to rave about the Pantera electronics parking brake controller using the original brake lever, those brakes are tight!

i had the willwood parking brake and you couldn’t adjust them enough to get them tight enough to do anytyng.

enough to do anytyng.

Replies sorted oldest to newest

Was the Wilwood parking brake that you replaced manual or electronic?

For the Tesla brakes, I think a person needs…

- Calipers

- Spacers /Adapters

- Harness with Connectors to Calipers

- Controller

- Switch

Anything I’m missing? Does PE sell all this stuff?

Thanks

You might also have to move your hydraulic caliper to the front position on the carrier because the electronic parking brake caliper is quite long and might collide with the shock absorber. Doing so would require longer flex brake lines. I just encountered this issue with the Wilwood electronic caliper. It definitely collides with the stock shock absorbers. The issue prompted me to upgrade to QA1 shocks which are much skinnier than stock Pantera shocks. I am hoping to leave the hydraulic calipers in the stock location.

I was on the fence about ditching the stock Pantera shocks and this issue made the decision easy.

There's no exhaust on a Tesla, I'd recommend you rotate that connector away from the hot exhaust if possible.

@rocky posted:For the Tesla brakes, I think a person needs…

- Calipers

- Spacers /Adapters

- Harness with Connectors to Calipers

- Controller

- Switch

Anything I’m missing? Does PE sell all this stuff?

Thanks

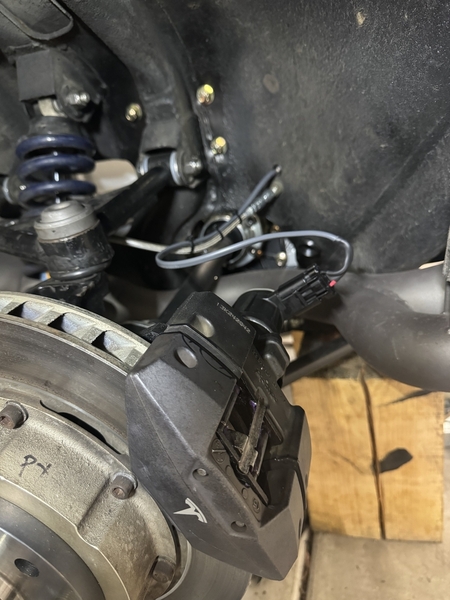

Everything but the calipers and the pads. The full calipers need to get moved to the front of the assembly. This is the right rear.

it’s up on jacks so there isn’t weight on the suspension. rotated and it’s too tight to the CV axles

i also put heat shield tape around them.

PE sells the mounting brackets and controller this kit uses the stock lever switch.

i have odd diameter rotors so i had new brackets fabricated also i had to put 1/4” spacers between the caliper halves for the width of the rotor (12.25 diameter 1.25 width)

i was unaware or the wilwood electric brake set up, i can only say the manual parking brakes are pretty useless.

I would do one or the other.. and i wouldn’t waste a cent on manual parking brakes

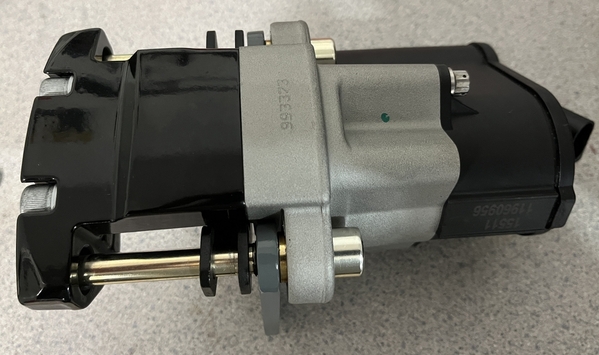

Here is a photo of the Wilwood electronic parking brake. It is being held in place by one bolt. The caliper is colliding with the stock shock absorber. I had been considering replacing the stock shocks with QA1's and this issue prompted me to go forward with it. The QA1's are a lot skinnier than stock shocks. I could flip the hydraulic caliper to the front position on the carrier and that would solve it. But doing so would need a longer flex line along with a new route for the longer line. I am hoping the QA1's allow the electronic caliper to fit as shown. The last photo shows the custom laser cut steel bracket by Dennis Quella for the electronic caliper.

Some aftermarket gas shocks like my late Konis can be mounted upside-down and work equally in either position. They also provide 30-or-so lbs of spring preload from the high pressure gas inside. Dunno if this solves the Tesla interference problem or makes it worse.

I have no interference issues using the Tesla EPB and the stock rear rotors.

I'm using 180° headers so I have no exhausts to contend with in the rear suspension.

I suspect that your issue stems from the switch to 1.25" thick rotors and how you needed to shim mountings to make things work?

In researching the entire project I was romanticized by the illustrations of the big Gp4 rear rotor setup but the entire concept of the Tesla EPB developed virtually overnight and redirected my thinking considerably.

It essentially enabled a practical application to what Ford did on the 1969 Boss 302 Trans Am cars. It enabled the practical use of the 1965 Mustang front brake caliper on the rear of the Pantera, because all of a sudden, there was a EPB to use that worked magnificently.

A big thick 1.25" rear rotor was no longer necessary and the stock Pantera rotor fit right into the concept.

What I missed though was the opportunity to improve the access to the Pantera rear rotor by going to this, https://www.speedwaymotors.com...set-Black,1995.html, "over the hub" rotor.

It is exactly the offset needed and in combination with the rotor it uses reduces the likeliness of over braking the rears by at least a mile.

All the offsets remain basically the same and therefore reduce or eliminate the potential interference issues back there.

I don't have time to continuously tear down and revise projects that have already been completed but admittedly, switching over the rear rotors to over the hub mountings is in the back of my mind and likely will become a compulsion at some point to do?

As I write this, I am feeling the urge now. Maybe it's just the effect of wanting to stay inside out of the summer heat? Who knows? Go figure but if anyone is contemplating this kind of a project, it would be foolish on your part to dismiss my writings as the work of a lunatic.

If all of the hardware changes aren't enough of an attraction to motivate you maybe just consider using polished stainless steel fasteners and chrome plating everything and wearing a gold dog chain necklace with WILWOOD or BREMBO as the nameplate?![]()

After all, this business of everything needing to say WILWOOD or BREMBO is just a current passing phase and like Taylor Swift will go by the waste side eventually and you will come to your senses? ![]()

Here is one thing that is on my mind for about 40 years….

back then I had the idea of exactly this kind of parking brake system… electric actuators for mechanical calipers… when I was in school in Germany for Master Mechanics….

I showed my teacher my drawings and explained my idea and here is his response:

”…your idea would work as a parking brake but it is NOT a valid proposal as this system has to serve as an emergency braking system as well! Your system can not be modulated and would lock up the rear wheels in the event of a general brake failure! … it has to serve as an E-brake (at least back then) The car would spin out of control….”

And that was the end of my Idea!

And I had quite a few more ideas that got shot down and are in use today.. 40 years later….😢

Electromagnetic actuated valves… hydraulically actuated variable cams.. Direct injection for gasoline powered engines…

40 years ago I drew them up and got told that my ideas aren’t working….

Don‘t know, who told you, but dircet fuel injection was invented 1954 by Mercedes Benz in the 300 SL, variable camshafts came from Toyota in1990. Only the electric parking brake came 2001 from Lancia in the Thesis…..

Teachers at school…

There was no internet back then…1988ish

I couldn’t validate my ideas back then…

At least I was not totally cuckoo…

I think what has happened is that in many places the wording describing the secondary brake has changed. It is no longer required to be an emergency brake and frankly at least in US cars it has always been impractical to attempt that usage.

In most cases now a dual master cylinder is your emergency brake in effect.

YOU had a very good idea. It all depends on who you show the idea to.

It has been "rumored" that Howard Hughes father bought the design of the oil well drilling bit from an engineer in a bar for a few hundred dollars.

That bit is the source of income for everything that they did.