Hall Pantera has made many many great improved parts for our cars but this is not one of them.

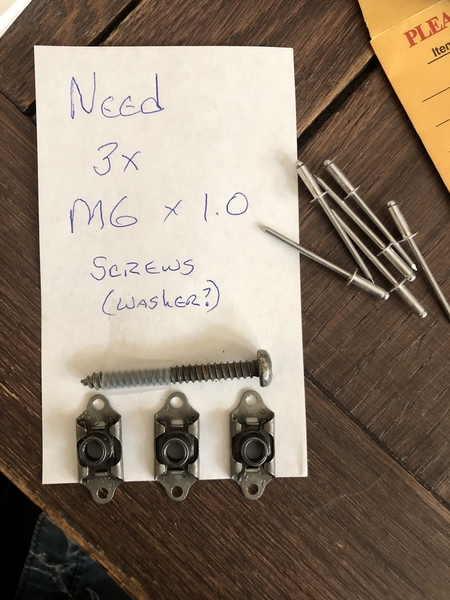

Many years ago I upgraded my power window motors. While doing this I replaced the cracked nylon arm rest attachments for the armrest screws. Hall offered (and still does) what I thought was a much improved design. It is a plate that you attach to the door. It uses a bolt instead of a screw. Seemed like an improvement .... But unfortunately the part that the bolt screws into is just pressed on to the plate.When you go to remove the bolt it will not come out. The nut attachment that is pressed on has broke free from the plate. The bolt will nut unscrew from the attachment. And with the door panel still in place there is no way to get at the attachment to hold it while you unscrew the bolt.The only solution was to carefully hacksaw off the bolt. I am now going back to the original still not great designed nylon & screw attachments.

Hall Pantera has made many many great improved parts for our cars but this is not one of them.

Hall Pantera has made many many great improved parts for our cars but this is not one of them.

Attachments

Original Post