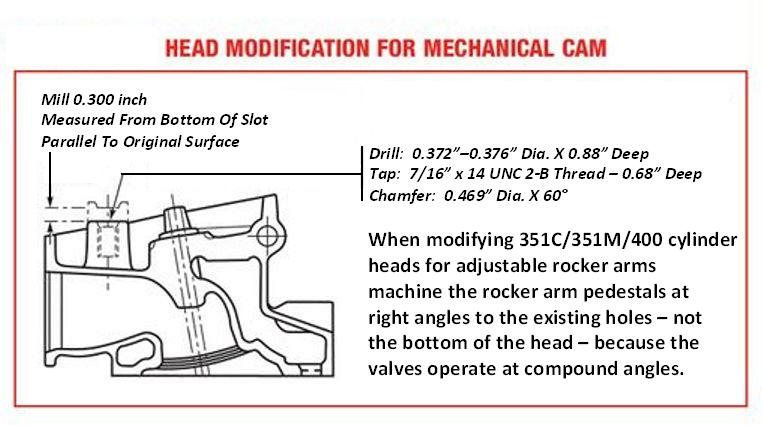

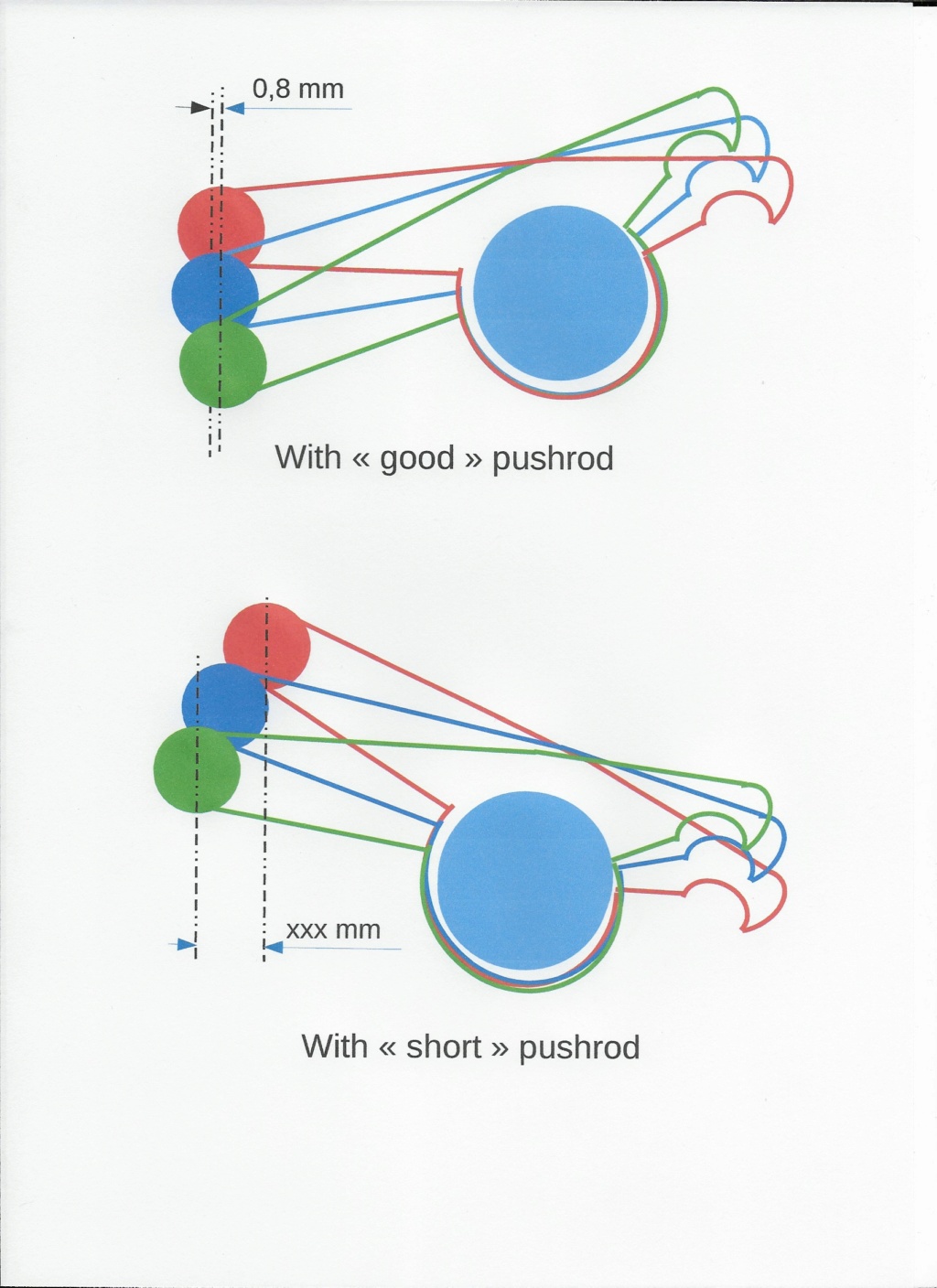

I agree- if pedestal machining is not done VERY carefully to make a faux 351-HO, pivot studs can become slightly misaligned. But keep in mind that- unless during full cam lift, the roller rocker wheel runs dangerously close to the edge of the valve stem tip, the overall effect of such slight misalignment only shortens the valve lift by a few thousandths of an inch. On a 450-bhp engine, that might remove 15 bhp, assuming correct length pushrods. Unless you are racing a 351-C for money, missing 1% of the potential horsepower of an engine is trivial. Use a bigger cam or higher dome pistons for more compression and you'll get extra power.

And that's only with roller tip rocker arms. Roller pivot/roller tip rockers do NOT increase power, they only reduce oil heating from sliding friction of the rocker arm sled-fulcrums and at the valve stem tip. And they are fussy to position correctly. With stock sliding-tip steel rockers, their tip radius is so large that a slight misalignment or non optimum pushrod length makes even less difference in power. Your current heads may work just fine with stock rockers- again, with correct pushrods.

Ford once offered a roller-bearing fulcrum for stock stud-mounted rocker arms, for the 1969 Boss 302 which also fits the 351-C & are legal in most race series. They were sometimes used on Gr-3 cars for endurance events and reduced a main source of friction and oil heating without using an oil cooler. The special roller bearing rocker arm fulcrums are no longer available but a good machinist could likely make some up from tool steel, once you find a local source of the drop-in roller bearings. This is shown, with (obsolete) part numbers in the Ford OHO (Off-Highway Only) books of the '70s, available for download on the POCA Website under 'Tech'.

All this can be avoided by buying today's far more efficient aluminum cylinder heads. They also remove 60+ lbs of needless weight mounted high on your engine. Good luck-