I’ve started working on the original engine for my pushbutton, wanting to replace the 550+ HP stroker madness in the car currently, with a close-to original smooth running 351C.

I have all the original engine parts, including the ’71 close chamber heads and the Ford aluminum D1ZX-9425-DA dual plane manifold. The block needs a 020 overbore.

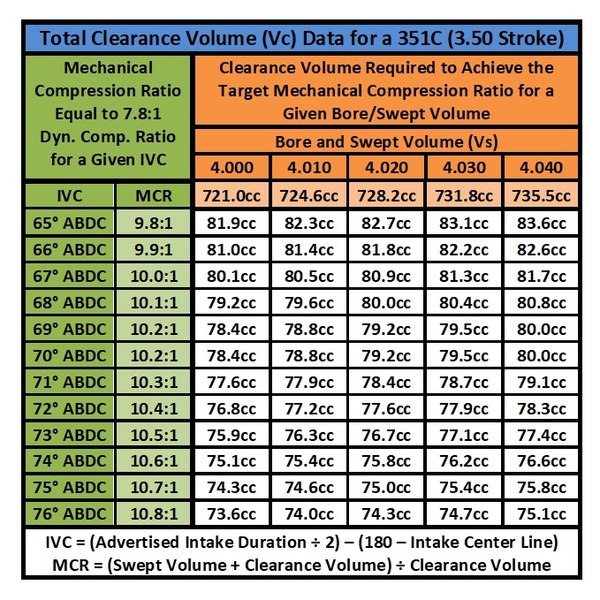

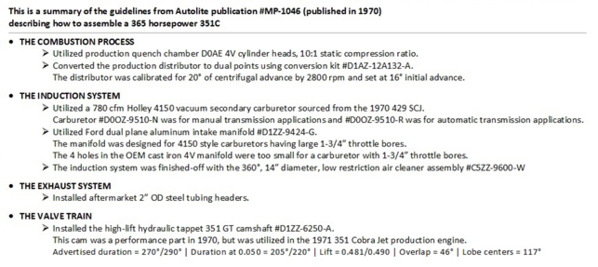

I'm thinking of replicating the Ford recommendation for a 365 HP 351C using the Cobra jet cam and flat-top piston in the M-code engine mentioned by George in Sticky 2.

I was intending to use the Ross 80556 round shirt pistons with the narrow 1/16 piston rings recommended by George, however, they only come in a 030 over version. As the block only need an 020 over bore, I would prefer restricting it to that, retaining the possibly of another engine fresh-up.

An alternative to the Ross piston is the JE 338200, a 4032 low expansion high silicon aluminum alloy heat treated piston that can be had in .020 on special order

https://www.jepistons.com/Products/338200.aspx, it has a comp. height of 1.660.

Other options are:

Sealed power Hypereutectic, Comp height 1.645

https://www.jegs.com/i/Sealed-...44/H555CP20/10002/-1

or:

Keith Black KB Performance Hypereutectic, comp. height 1.70

https://www.summitracing.com/i...0/overview/make/ford

QUESTION: I’m not going to use this engine for racing so would Hypereutectic pistons like the Keith Black 108-020 be suitable for this type of engine. I would prefer the KBs over the Sealed Power , as they use the thinner 1/16 and 3/16 rings:

This is the description for the piston:

"Keith Black hypereutectic pistons are made from 390 aluminum alloy and heat-treated to T6 standards, which makes them 30 percent stronger than ordinary untreated hypereutectics. Their 100 percent CNC-machined crowns, high upper compression-ring location, gas-accumulator groove, drilled oil returns, and spiral-lock retainer grooves make these pistons outstanding for performance applications. They have a lightweight, rigid-rib skirt design that stabilizes the piston in the bore. All of this adds up to pistons that fit tighter than forged types, provide improved oil control, reduce blowby, increase ring life, eliminate cold start-up knocking"

Thoughts??