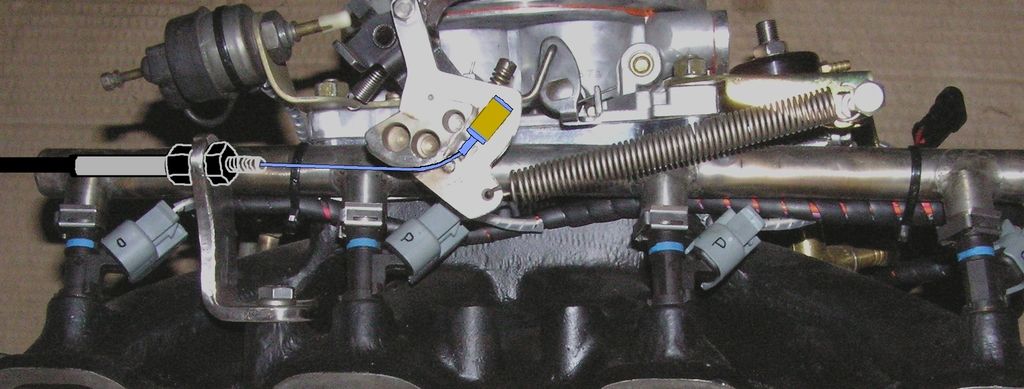

Can any one tell me what cable is pictured? Is it origional? Should i have a better configuration? Any PN/vendor recommendations? My carb is a Holley 4150. [IMG:left]

[/IMG]

[/IMG] [/IMG]

[/IMG]Replies sorted oldest to newest

quote:Originally posted by Aus Ford:

The bottom right switch controlled a full throttle enrichment system, which as it turns out i no longer use as i found another way of doing that.

The upper left switch resets a overrun fuel cut off system that is actuated by a slight touch on the brake pedal. A manifold vacuum switch also resets that system restarting fuel flow.

I dont use that system all that much now that i went to EFI but i used it all the time back when i was using a carburettor.

quote:Originally posted by George P:

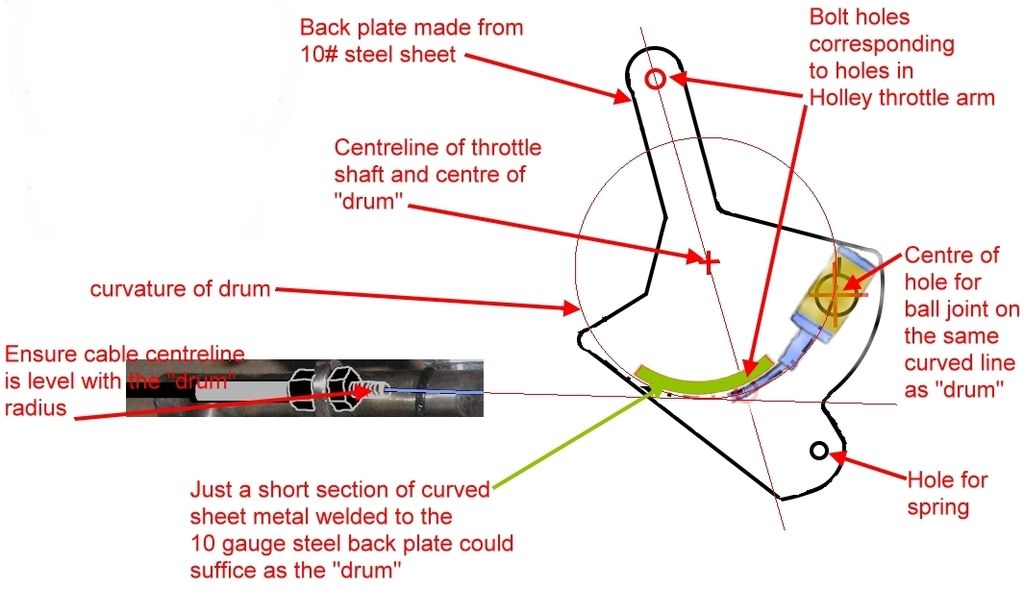

In terms of achieving full throttle actuation this has always worked for me.

Attachment arm 45° off vertical & cable attachment point in-line with throttle cable at idle & WFO.

But I will emphasize (confess?) those relationships need to be quite precise.

Lyle that cable drum thing you installed is bitchen.

quote:

Originally posted by pantera chris:

... Your approach is for a front engine car ...

quote:Originally posted by mike the snake:

I did not make that last post, must have been some mixup.

I AM dealing with throttle cable issues right now though. I found an outfit called LOKAR, and another called "Performace Cables" that can fab up anything you might need.