All,

Replies sorted oldest to newest

Larry,

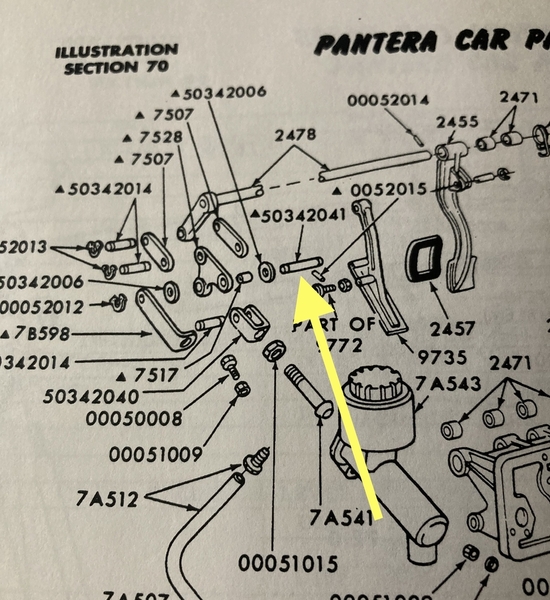

I just made one a few weeks ago. I have my front trunk tore apart and have the pedal box out at this very moment. I have a replacement that came with the vendor supplied aluminum reduction kit but it was shorter than the stock one I took out of my car and did not have the hole bored through for the roll pin. I made one from precision ground 4140 stock sourced from McMaster Carr. The stock was more than what Wilkinson is selling them for. What we don’t know is the material they are made from. 4140 is vary hard and should last as long as I own the car.

There is just enough corrosion on the old shaft in the mounting area to make it a tight fit. I can only assume dissimilar metal that’s been in contact for 50 years. The outside of the shaft measures exactly the same as the new stock. The new shaft is a loose fit in the aluminum boss. I used Loctite 660 when I assembled it and a new 2mm x 22mm roll pin. It’s solid as a rock now. Be aware that the roll pin is offset to one end by about 0.030”.

Damn, I love the DeTomaso family.

thanks, that is exactly what I need. What I’m trying to do is replace that troublesome design with a pivot pin and carriage clip as I have previously done on my two MC clevis fittings.

this is on a local car getting put back together and the pedal box is all hooked up, but he just found the little 3 inch support bracket that was not installed on the clutch effort reduction kit. Thinking the new pin and carriage clip is the easiest solution.

now to see if I can find a 10 mm by 90-100mm pin…..

you make a good point on the hardness of this pin, and the replacement pins I am using are likely softer than the OEM pins. I rationalize my choice by telling myself to keep spares on hand, and if it starts to show wear it is an easy replacement, the motive for the style change in the first place.

Larry

Larry,

I'm not sure a floating pin is a good idea for this application. The amount of force placed on the shaft by the clutch linkage could cause a problem with the aluminum boss wearing if the shaft is allowed to move. Might be the reason the roll pin is there. Furthermore, the support bracket "7B598" above needs to be there, again because of the force applied to the shaft. I thought about drilling holes for hair pins but opted to use E-Clips. The E-Clips are not hard to remove with a small screwdriver.

I have never had problems removing an E-clip.

Putting them back on, especially on that shaft under the dashboard, is an entirely different thing……

🤬🤬

Larry