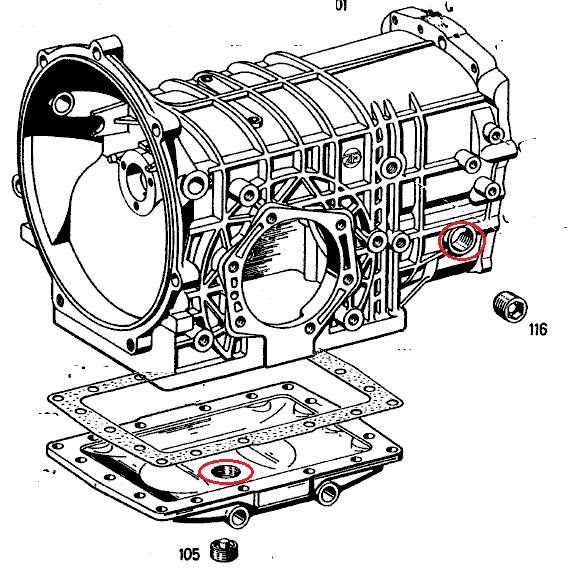

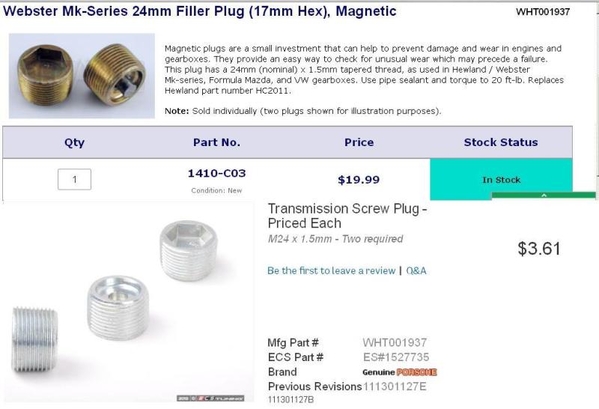

..I use to use the funnel with a hose...until I drilled and tapped the plug 3/8" NPT, for a elbow, adaptor and a oil temp sensor. I can testify, the sensor has no problem getting heated from oil splash. Also the air cavity will have the same temp. You should have kept your sensor in place, but you would always see a normal temp of 187F to 194F degrees! Just coming off a high speed run on the Freeway!

Enjoy the photos.

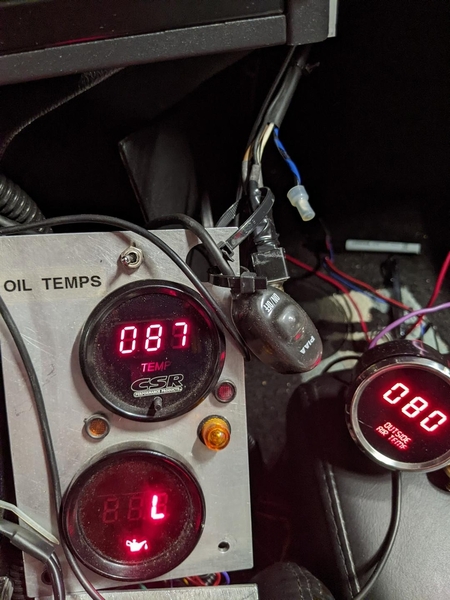

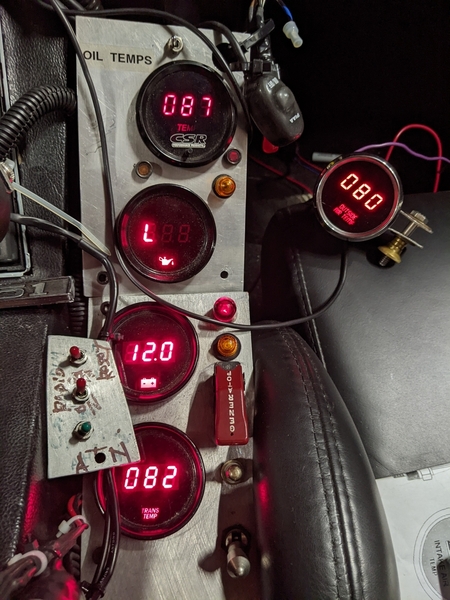

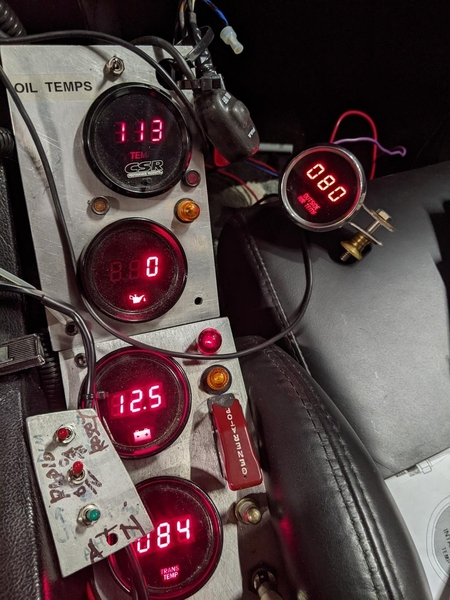

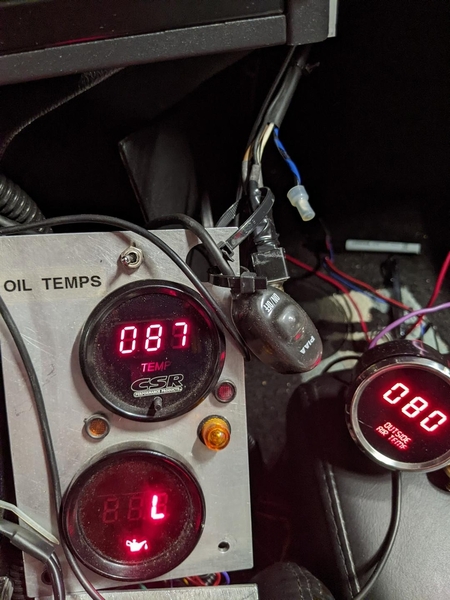

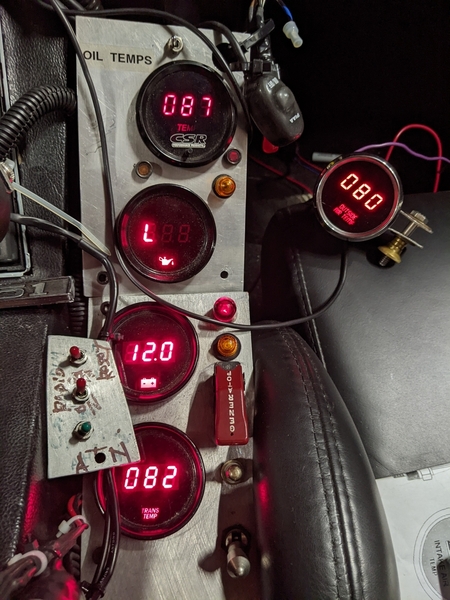

The TOP gauge sees the engine coolant temp, separate from the Oil Temp gauge at the BOTTOM of the row. The Mini Toggle switch at the very Top of the panel...switches the oil temp gauge, Left for Engine oil, right for Transaxle oil temps.

The gauge at the very for right, UN-mounted is ambient temps. The sensor is suppose to be outside the car, at this moment is in cabin. Mounting In process.

The thin Gauge directly in front of the CD Deck is a digital for 'Fuel Pressure'. Very Safe way to do it.

The Volt gauge is at 11 volts until engine is fired then charges at 14.1 volts. The Oil pressure is at 'LOW' with engine off then, when running, shows 51 PSIG, but the (1) Filament has burned-out long ago.

The row of 4 gauges is, from top to bottom Engine Water Temp, Engine Oil PRESSURE, VOLTS, Eng/Xrans Oil Temps.

One photo shows Upper left corner Digital Tachometer, Aircraft Clock will show 3 at will, Chronometer, Elapsed Timer, Real Time.

Why Digital gauges instead of Analog??

With Analog gauges: they take time to Read! First you must identify the gauge, what the Lines and Numbers represent, last at which line is the Needle pointing to, or in between...Exactly!

With Digital Gauges...first, RED Light Does Not Spoil your Night Vision, why they use them in Aircraft. And they are bright or dimmable. All you are required to do is Identify the Gauge you are looking at, and the Exact Numbers are right there!! Accurate To the 0.1!

Ask all the questions you wish.

The Engine Temps would run over 250F (gauge Blinking), cruising the Freeways at 85 MPH,

Constant. When I turn on the Cooling Fan on the Rear Cooler, Oil temps drop to 227F, and that reading is taken 'Before' the Cooler, after circulating through the Engine! Believe it or not.

Constant. When I turn on the Cooling Fan on the Rear Cooler, Oil temps drop to 227F, and that reading is taken 'Before' the Cooler, after circulating through the Engine! Believe it or not.

MJ

Bolts have been tighten.

Bolts have been tighten.