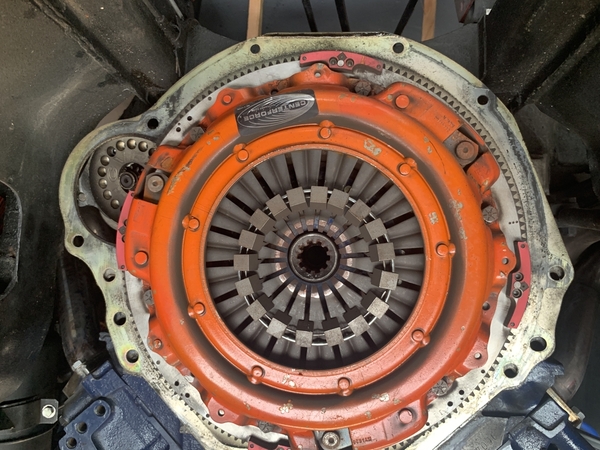

I am working on my engine and it is mostly disassembled. Only the crankshaft remains at this time. When I spin the crankshaft using a ratchet on the balancer bolt there are scraping noises coming out of the clutch area as you can hear in the short video below. Also, it has an old Centerforce clutch and hydraulic throwout bearing. Any ideas about the source of the noise?

Replies sorted oldest to newest

The inside of the flywheel may be scraping on the inner plate that goes between the block and the bellhousing?

I think I had that happen on one of my builds…. I think I had to find a different one?

Rocky

Thanks Chuck. I will check.

Check the clearance on the two internal machine screws at the bottom of the bellhousing to the gearbox. The clearance here is incredibly tight. if there is any slight brightness on the edge of the screws you have found your noise. you can get the same HS Machine head screws with a low profile head which will give you another 2.5-3.5mm clearance.

I think I can see some scrape marks in the paint on the back of the clutch housing.

@rocky posted:The inside of the flywheel may be scraping on the inner plate that goes between the block and the bellhousing?

I think I had that happen on one of my builds…. I think I had to find a different one?

Rocky

Yes! The clearances in there are very tight. When the bell is off, there is nothing to press the plate against the block. That is likely the source of the noise.

You also need to verify that the bolts that retain the pressure plate to the flywheel are not excessively long and the tips rubbing on that plate.

Also, check the fingers on the pressure plate for excessive wear on the tips. I found out the hard way that the Centerforce pressure plate fingers are not hardened enough to ride in constant contact with the throw out bearing.

Mine were worn almost half way through. That was with 3,000 miles on the clutch.

I complained to "Gene" at Centerforce that they weren't hardened at all and just painted black. He offered to replace it for $150 under warranty so run at your own risk.

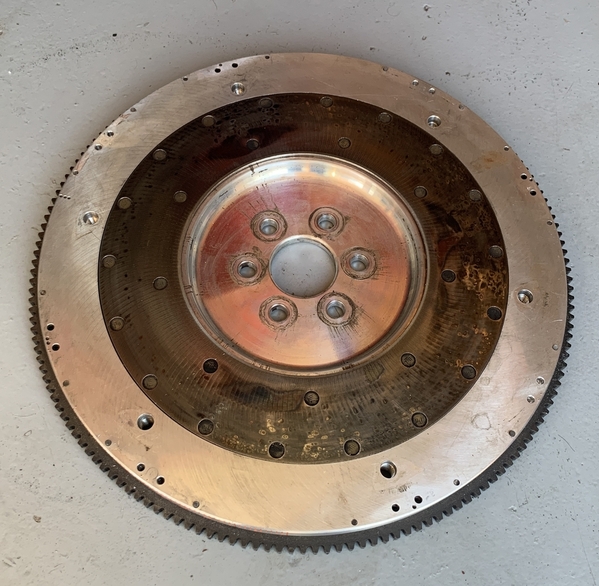

The disc is also dual durameter/friction, i.e., one side is harder then the other. The harder side is on the flywheel side. You MUST run a FORGED steel flywheel OR ELSE the disc will machine itself into your cast iron flywheel.

Make sure that even when running a forged flywheel that you have it resurfaced by an experienced shop. That Centerforce disc has a big tendency of developing hot spots or high spots on the surface of the flywheel.

The dual friction sounds like a good idea but has got some issues with it including quality of manufacture.

Incidentally, "Gene" mentioned that they were now being manufactured "off shore" and that was a suggestion about the "lack of quality" issues that I was experiencing with it.

He will never admit to anything and frankly why should he care if you are foolish enough to pay for a replacement part under warranty?

Thanks Doug.

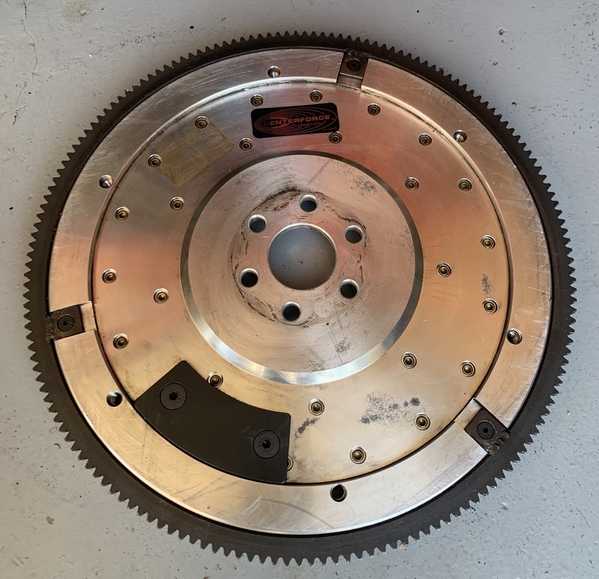

The Centerforce clutch has been working well. There is plenty of metal on the diaphragm fingers. I will check bolt length when reinstalling the pressure plate. The flywheel is Centerforce as well. It is a combination of aluminum and steel, and it seems in good shape.

I think the source of the noise was the sheetmetal block protection plate. I could see that it is warped after removing it. I may just eliminate it (make the bottom part into a dust shield for the flywheel).

Here is the Centerforce flywheel.