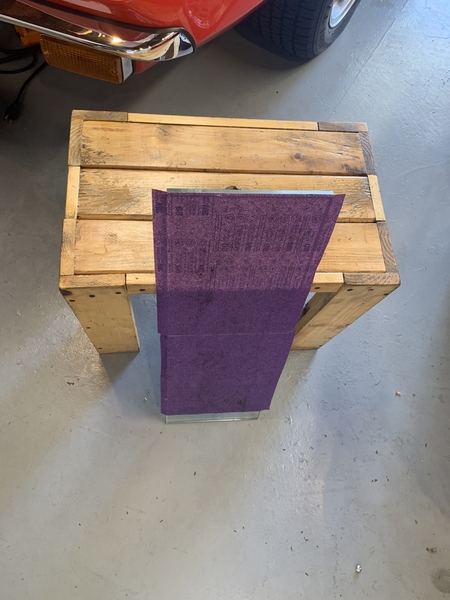

I had to replace a head gasket and needed to do a better job of preparing surfaces that contact the gaskets. I could have taken the cylinder head to a shop where they could put it on their machine that essentially sands the surface but I came across a way to do the same in my garage. The block is a thick glass shelf (8" x 24") with two sheets of 80 grit sand paper attached with spray adhesive. I laid the block on the garage floor with a piece of old yoga mat in between to keep the glass from sliding and then moved the cylinder head back and forth on the block. It only took about one minute of sanding and the surface looked perfect. The sanding block can also be used on the deck of the cylinder bank but you have to make sure no debris gets into the bores and lifter valley.

Replies sorted oldest to newest

I like the idea but I was really hoping for a photograph of one of the finished cylinder heads. 🤷♂️😉

Larry

I thought about that as well but it was after the engine was reassembled and running. I am hopeful that the engine stays that way and a photo op for the sanded finish is not lurking around the corner.

What type of head gasket did you use? I wish it wasn't an MLS because those joints require a much better surface finish than you get with 80 grit sandpaper.

I am using FelPro 8347PT1. From FelPro's installation guide: "Roughness Average (Ra) is the average micro-inch measurement of peak-to-valley roughness height of a flat surface. The lower the Ra number, the smoother the surface. Fel-Pro recommends a finish of 60 to 80 Ra for cast iron cylinder heads"

Using the chart below it show 80 grit puts the surface at 70 roughness, the ideal roughness per FelPro. Am I misinterpreting this?

US Grit UK Grit Ra Ra

ref Ref. µm µ inch

120 3 125

180 2 85

80 1.65 70

240 1.50 50

320 0.75 30

180 0.62 25

240 0.45 18

500 0.40 15

320 0.25 10I think this it's fine for a composite gasket like 8347PT1. MLS gaskets require instead Ra between 30 and 60.

Attachments

Steve

there are two critical things when it comes to refreshing a cylinder head surface ….. how clean they are, and how uniformly flat they are.

Those heads certainly appear to be clean, but have you done any checks for flatness?

A machine shop test would be best, but a good straight edge, and some back lighting could give a good seat-of-the-pants evaluation.

Is it possible to do some sort of a test like is done on body work, using two colors of primer to find high and low spots? Metal bluing solution and crocus cloth?

🤷♂️🤷♂️

Larry

Larry,

These heads were at a shop 1,000 miles ago for a complete valve job including head resurfacing. The engine was assembled at that time and has not been overheated (just over rev'd a bit). It looks like this head was still flat when I removed it this week. There was the typical amount of carbon and gasket material on the head. If it was warped, that would have shown up while sanding on the flat glass block. There would have been pockets of dirty areas surrounded by clean surfaces.

I also used a straight edge to ensure flatness of this cylinder head. To your point It is better to know now if there is a flatness problem than after the engine is assembled and being tested.

Thanks, Steve

...Beautiful!! Sanded on a 'Surface Plate'...I would 'Bet My Paycheck' it is True. The Best Finish I have seen on any Iron Head. Well Done!

MJ

Thank you for the backstory, Steve.

armed with the information you just shared, I see your approach as being inventive and effective.

👍👍

Larry

I have a section of polished granite countertop I use as a surface plate. It is quite flat.

The place near me that rents hardwood floor sanding equipment sells large sheets (12"x18") of sand paper in various grits that work nicely for dressing larger surfaces.

...Technically, 'Sandpaper' is for Wood, For Metal, we use 'Emery-Cloth'.

MJ