The bushings on my car were aftermarket and the inside diameter of the sleeve was larger than stock. I am converting to poly bushings which have the same inside diameter sleeve as stock. The bolts on the car before won’t fit as they are too large in diameter. I was looking to order some bolts from aircraft spruce but am a little fuzzy on the sizing. The stock bolts are 12Mx1.75x80mm for the upper A Arm to chassis brackets.

Converting this to AN seems to be 12M=AN7.

80mm = 3 5/32 so I am thinking -31 (3 7/32) is the closest in the aircraft spruce chart.

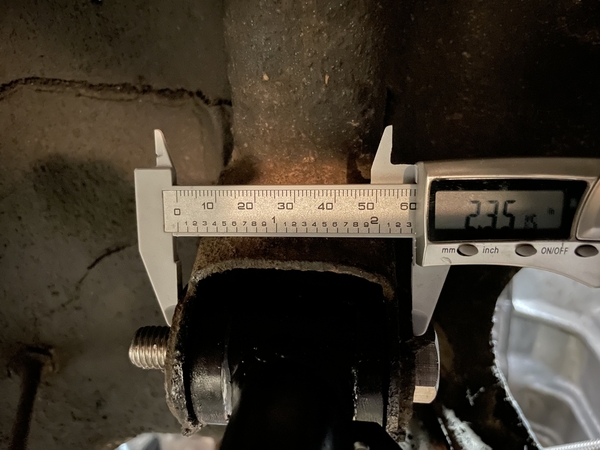

I’m getting a little tripped up in the what the grip size of the bolt should be. Should the grip run fully through the bracket and bushing? Seems like it should so the threads don’t chew through the bushing. I have included a picture of a metic bolt that is 12Mx1.75x80mm but as you can see the grip isn’t as long as the the width of the bracket and bushing (2.35”). Am I overthinking this? Thanks.