When midlife crisis hits and the only cure seems to be an Italian mid engine car - then the Pantera is the perfect drug!

Having built a 68 Mustang previously the thing I know was that I wanted a car that could handle, not only red light races but corners as well!

And since I really love those massive wheel arches on the Group 4 cars my mind got set on building a full out race car.

Or, well, maybe. Wouldn’t it be nice if I was able to drive it on public roads? Or even Historic Racing? Or why not all of the above?!

Anyhow, finding a car that I wouldn’t feel bad about converting to a race~ish looking car had begun!

In late 2017 I followed a lead from a Swedish Pantera forum and eventually found 4899 - in a garden shed, where it had been sitting for the past 20 years! Engine blown, only bits and pieces left. Floors all cut out (the classic ”previous owner restauration” condition).

But all vital parts, well except the engine, was there. And the rusty areas didn’t seem to bad. (Amazing what a thick layer of undercoating can hide!)

Since I don’t have the skills and tools to weld and fabricate the task went to Tokan at Stockholm Speed Industry.

As of now, the first part of the build, getting a rolling chassie, is about done.

The next stage will be to put her back on the road, spring/summer 2020.

As I found it - didnt look to bad, right?

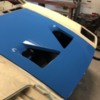

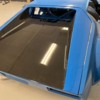

Engine bay looks great. And once we welded it to the frame (the whole body was off by an inch from left front to rear right,) we test fitted the Group 4 flares.

But once we started cutting the rockers we found three(!?!) layers of rusted patches, just welded on top of each other. And the frame rails was just.. well, nothing. So we started from gound up.

Car was sent off to media blasting and came back as the love child of Dr Frankenstein and a wannabe TIG-welder. A blind one at that!

EVERY single panel of the car was either rusted through or/and had been patched, welded, patched again. And in some cases, as with the rear frame rails, they hadn't even bother welding. They where just folded and tucked into places behind the wheels.

At this stage there where two possible routes to take. One to the scrap yard and the other to the bank for more money!

That nice looking engine bay was in fact 2 inches of bondo! Took the blaster two days to remove it all.

It was clear nothing could be saved. And since that was the case the guys at SSI could go all out! The floor was reveresed, so its completely flat underneeth and all rails are on the inside. Full restructuring of inner and outer rocker panels. Full roll cage. Completely new rear wheel structure, tho following the original look but with a twist.

Also test fitted the pedal box ( http://pengineering.com.au/product-pe-pedal-box ) and seat, full custom Tillett FIA approved carbon fibre. (https://www.tillett.co.uk/ )

The whole front was cut out. (Or rahter fell out after media blasting). The car has seen some frontal damage as well so the nose need remodeling. A fuel cell will be fitted up front later on.

Resting on BBS E50's (10x16 front and 14x16 rear) with Good Year rubber, Intrax dampers and AP Racing calipers. Also sourced a Cleveland XE block and CHI 4V heads. But we'll see how the engine ends up. There are lots of ideas. Custom flat crank is one of them...

So, end of build part #1. Next up is body and final fabrication. Just need to sell my last kidney..