quote:

Originally posted by Cowboy from Hell:

quote:

Originally posted by ItalFord:

... The Maserati Bora we have owned since 1977 has never given us any problems what so ever. The car runs smooth and never changes its tune with the wind. I wonder if this is a function of the build / system quality? Don't know. Why would'nt the pantera system be so unreliable ...

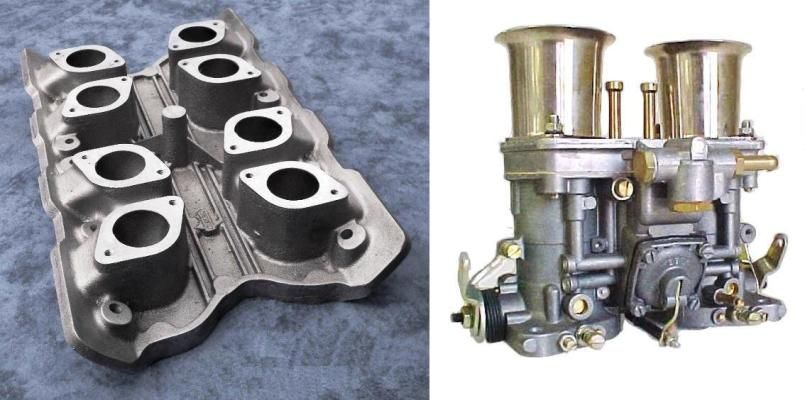

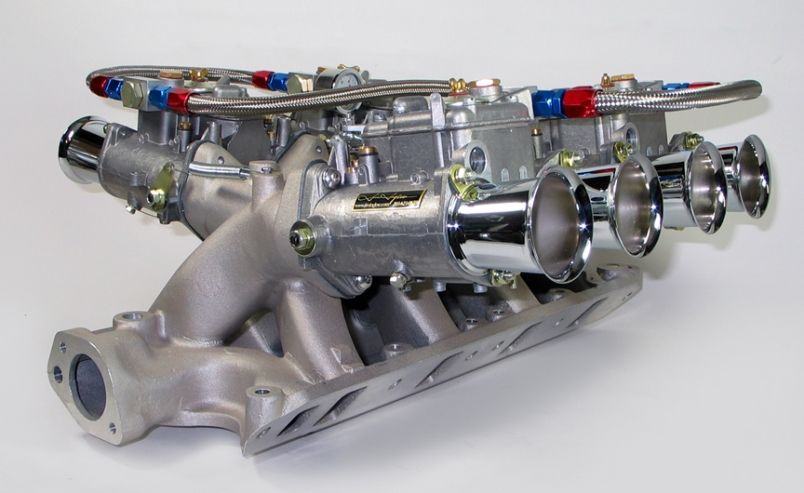

Every single cylinder internal combustion engine ever built has been equipped with independent runner induction. (single cylinder street motorcycles, dirt bikes, lawnmowers, power edgers, garden tillers, chain saws, leaf blowers, portable generators, cement mixers, construction air compressors, portable arc welders, motor boat engines, the list goes on and on). Multi-cylinder engines found on a lot of sporting equipment like "sport bikes" and several sports cars have also been equipped with carbureted IR systems. Ferraris, Maseratis, Lamborghinis, Porsches, Alfas, Lotus, Jaguars, Aston Martins ... even a European Ford Escort was equipped with IDF Webers.

There is an overwheling amount of evidence that an IR system can be a reliable and drivable induction system for a street automobile. It is a combination of carburetor set-up and camshaft design that will most influence the success. The things in a camshaft's design that will hurt an IR system are too much overlap, overlap that is not centered on TDC, or a late closing intake valve.

Modern camshaft design with narrow lobe separation, lots of overlap, a steep and narrow torque curve, a lopey idle, and a tire frying low rpm powerband is not a good match for an IR induction system. This is why Inglese Systems sells camshafts to compliment their induction systems; all of their camshafts have 115 degree lobe separation angles. My camshaft spec that I call the Cobra Jet cam would make a good cam for an IR system too. The 351C 4V cylinder head imbues a motor with a wide flat torque curve and therefore a wide flat powerband, with a strong mid-range rush. My camshaft spec was set-up to compliment that type of powerband. This type of torque curve and powerband is an ideal characterisitic for an IR induction system too, IR induction is very good at operating over a wide powerband with a strong mid-range rush. I am convinced the 351C 4V cylinder head was designed with IR induction in mind.

One problem I have encountered is that some people are not willing to give up their "hot rod camshaft" when they install an IR system; in being stubborn like that they've already destined their project to doom, in my opinion.

-G

What essentially you are saying is that it is the camshaft timing creating the "problems" with the system. I can't disagree with it BUT 1) when these systems were raced in competition back in the day, they were run with radical race cams with no regard to reversion in the intake manifold. 2) I personally have been runing a solid lifter cam with 74 degrees of overlap, since 1981. The issues with that are over rated.

My car was set up in 1980. There were no special "Weber cam" grinds in existence then. Inglese was talking about having one ground and trying it.

First off, Jim Inglese had nothing to do with that "Weber" camshaft design. You give the criteria to the cam grinder and they design it. It is now sold by Comp Cams but was originally a Cam Techniques profile. That cam is hydraulic lifter. Even though it has .581 lift lacks top end big time on the track. It really is a 6000rpm limit cam. It really isn't what you want to run with the Webers.

Jim's role model was Dean Moon. He wanted to have his decals on all the race cars like the Moon eyes, but the eyes were taken. That company is now owned by the Holley conglomerate which is also CompCams, is based in Tennessee and has nothing to do with him.

Jim has reemerged as a Weber tuner and is still in North Branford, CT. He was at the most recent SAAC Convention at Watkins Glenn, NY, seen tuning running systems on some of the cars. He is a good source for tuning these systems. I'd recommend him to you.

Contrary to other comments, once tuned, the carbs do not come out of tune. What happens is that when you have a "bad air" situation with the atmosphere, the drop in power is so dramatic that people assume there is something wrong. There isn't. This happens with Holley single 4v carbs also.

The Weber cam was made so that people's air filters wouldn't catch on fire. This is a race set up. It is intended to be run with WITHOUT air filters.

I will point out that the 69Boss 302 Trans Am cars with the dual Holley Domination Holleys and the special individual runner manifold exhibit the exact reversion characteristics as the Webers do.

The solution there is to use a "carb cover" that is a certain distance from the carb inlets so that the fuel droplets accumulate on the inside of the "air cleaner top", drain and cause no fire hazard.

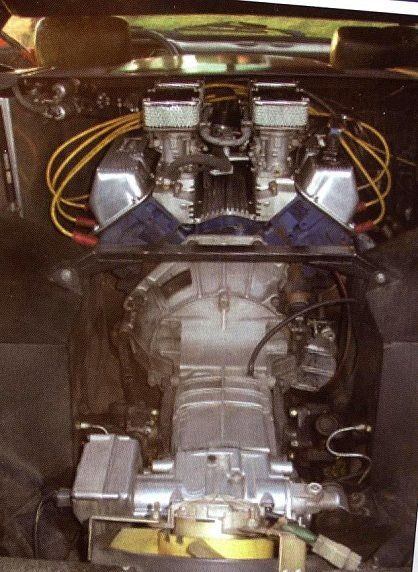

Not coincidentally, the GT40 Mark 1 had a cookie tray cover over the top of the carbs. There is no question in my mind why it was put there. That engine ran Fords "LeMans cam" (which can be run on the street) which has 82 degrees of overlap and advertised 321 degrees of duration. You might say that it was designed for that combination, no air filters, just open stacks.

That car, the GT40 MkI, without the cookie tray will fog the rear window with fuel droplets.

The "Weber cam" is nothing other then a compromise to this reversion issue caused by an IR manifold. The 28 degree over lap that it gives you doesn't eliminate it. It reduces the reversion.

I have found that the "cloud" of fuel vapor "hangs" just over the top of the standard 2-1/2" high velocity stacks.

If you use 5" tall stacks it will stay inside of the stack.

The 5" stack fits very well into the Pantera engine compartment dimensions. Just put screens over them. That's all you need.

48ida's don't like air filters and in particular ones made with paper.

The "Weber" cam also cuts the testicles off of the system. If you want to reduce the power down to 380 to 400hp from 550 to 600, that's the cam to run, absolutely. If you want power from the system, do not use the Weber cam. It is down well over 100 hp at the wheels.

The back fire really isn't one at all. You are actually seeing the opening of the intake valve and the cam timing allows you to see the flame. i've found that in the case of the Ford 351c with Webers that you want to run the AF42 plug rather then the AF32 that you would normally run with a high compression stock iron head.

You actually will get a similar reaction with a 360 or 180 single four barrel (or 2v) with a center plenum, if your choke opens too fast before the engine is warmed.

The aluminum heads are even more sensitive to plug temp range then the iron. They are players in the "back fire" since part of that is blowing carbon off of a partially fouled plug. Run a hotter plug. It helps.