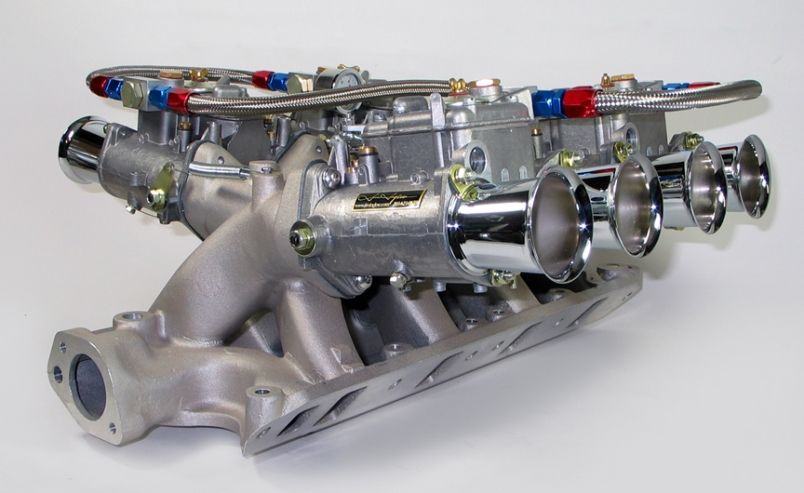

Fregola is only useful for some of the obscure fittings (in my setup) like the 1/16 NPT to -4 adapters.

www.anplumbing.com for the Earls.

This set up will still work for your set up too. The fuel/vacuum log ports can be reversed from the outside to the center of the log.

The vacuum tubes clear the valve covers by an inch and tuck in well below the top of the covers.

You could strip the entire system down not directly involved in the induction and completely rebuild it (presuming you had all the parts ready) in about an hour, including the carbs) without having to remove anything not involved in the induction to get at it, and yet it still tucks in to the engine compartment.

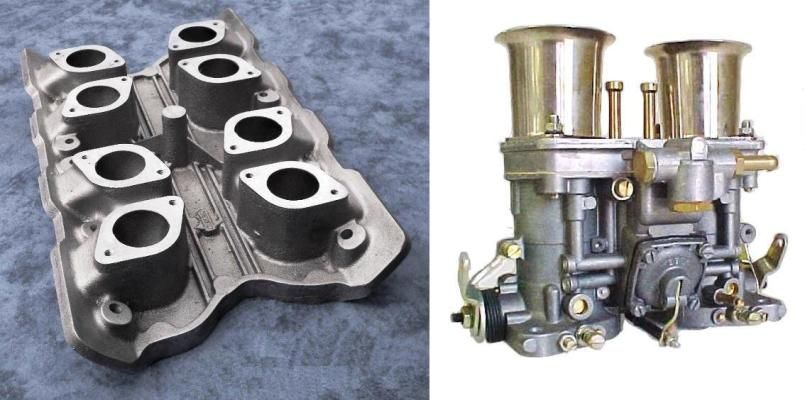

The difficult thing in that set up, internal valley location, will be drilling the manifold for the adapters. There isn't a lot of room to work with on the cast Weber manifold. Whose 3 piece intake are you using, Kinsler?

I only saw that manifold on Charlie Kemps Mustang and not up close to check the details on it.

You are going to need a 90 degree drill and short bits to do the Hall in the internal valley location. For performance it would be the best manifold to use. The Australian manifolds are all shorter so there is some performance give away to them because of that.

You also need a professional level tubing bender and flaring tool and a few days of work with some trial and error.

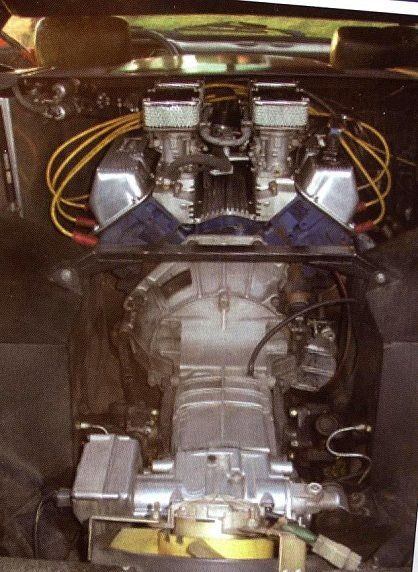

The Classic Fuel injection would be the way to go though. Those are the Weber IDA look alike bodies and have no external fuel rails.

They are the most expensive of the systems. Around $2800 without the manifold.

Any way you decide, it is going to keep you busy for quite a while. There is a lot of engineering you will need to do for the Pantera that no one does. They just set them up for a Cleveland and that's the easy part.

Engineering it for your car is the tough part, but for me it's fun and keeps me out of trouble.

The hard lines solve a lot of issues and create virtually none.

The problem with these set ups is people turn this strictly into aesthetics and it's like trying to shop for furniture with your wife. You like the black leather with the table over there and she likes the pink flowered pattern with the lace doilies?

Mine will stand up to function and practicality both for street and full out race. Everything has maximum serviceability.

For instance, a lot of people criticize my headers. They don't like the flange where they bolt together in the middle. They think the tubes are too big. They are 2".

Precision Proformance (Ford Power Parts made these for Hall) will make them for you now in one piece without the flange. Some others will as well now. These cost me $800. You can't beat that, so...a little ugly is ok right?

The problem with that is that you are going to have a tough time getting them on the engine without bending them over the heads or removing the heads (or one of them) to get them on.

With the current taste in one piece 180 headers, if you need to remove them to service the engine(like for redoing the valves in the heads) you are going to have a hell of a time with the headers and good luck on getting them back on.

You are going to discover that the engine heat has warped them up pretty good and that the bolt holes won't line up on the flanges?

If you are going to stay with under car design headers like the GTS design, you are going to discover they don't work well and give away about 100hp to the same setup in a Mustang.

When the Cleveland was still in production Ford recommended headers 2" od, 36" long with a 3-1/2" collector, 9" long. Do you see that in the under car Pantera headers anywhere?

I guess I do have a problem with that because if I was going to spend $5000 to $6000 for the induction, the exhaust better work too?

My point here is if I was going to run under car headers, the vacuum plumbing likely would have a different solution. For one thing, I wouldn't need a heat shield from the headers.

People have to learn the hard way unfortunately, including me. Maybe this is why the Panteras never seem to get finished?

Here at least my solution will give others ideas and my posts will have served a Pantera community service. You can get a lot of the fittings in red also. You don't need to stay with blue.

Even the tubes could be black.

Nothing that I know of in the setup is available in pink though. Just so you should know. Just in case your wife asks?

The "Doug Nash" IR magnesium intake was a three piece manifold. It was made that way so it could be used on any engine using a Boss or Cleveland head just by changing the valley plate.

Nash used three or four socket head screws to bolt the plate to each of the two separate manifolds.

Your's sounds like this. Just bolt the three pieces together on the bottom where no one will see that.

Good luck.