I've cut and pasted comments from five posts to create a composite announcement

Scott designed and manufactures the oem appearing two plane intake manifold for CHI 3V heads

quote:

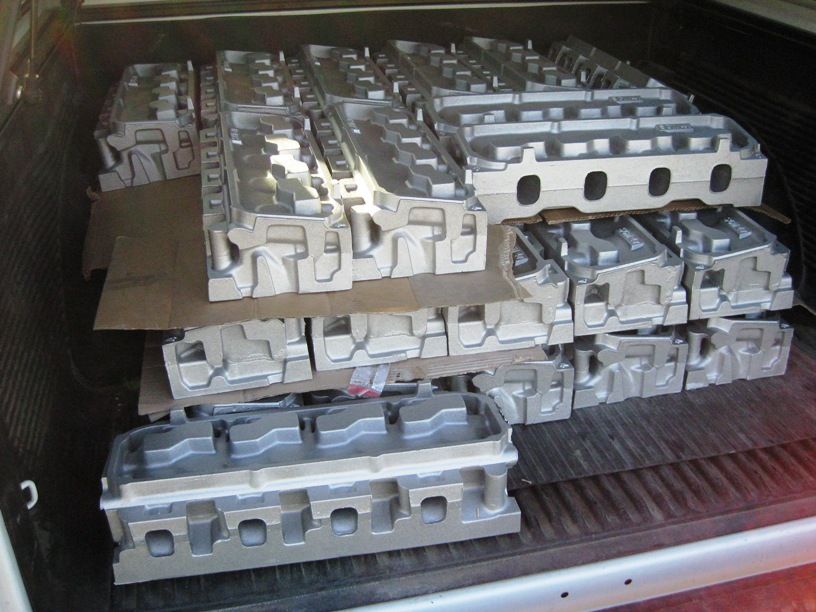

Pattern's for my new cylinder head will be finally finished this weekend( 2+ years in the making) They'll be off to the foundry on Tuesday.

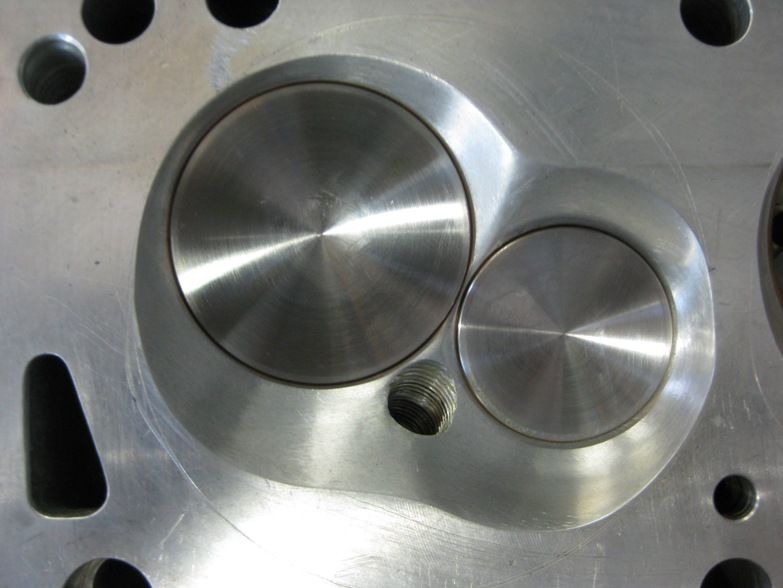

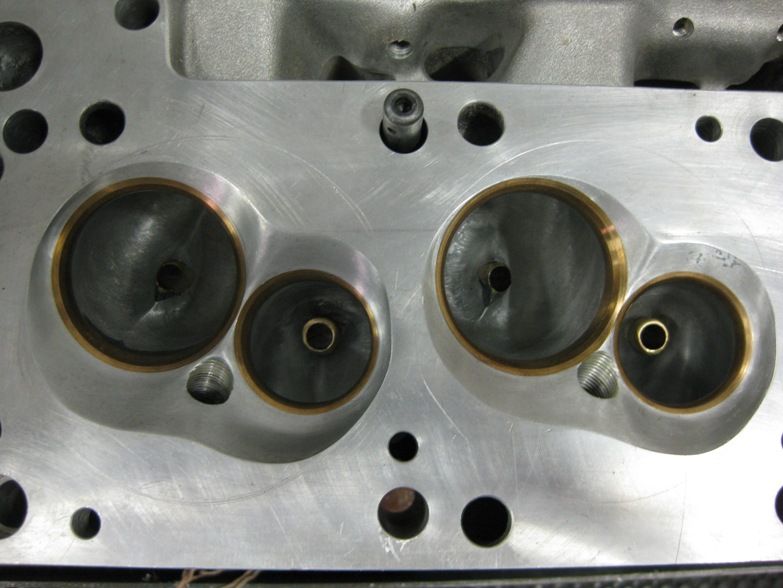

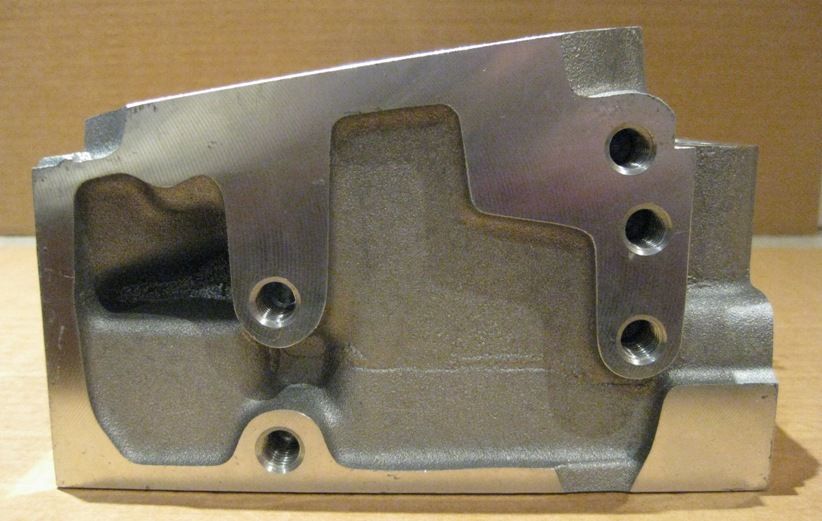

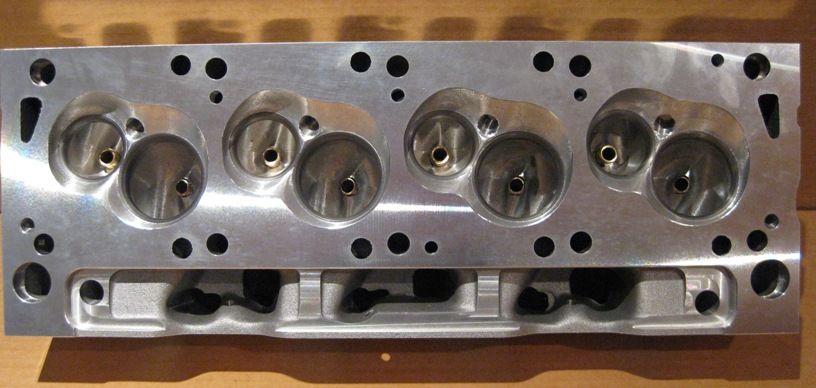

The casting is stock appearing. It even has a number "4" cast into the corner of the head. All my castings will have CNC machined ports & chambers. Combustion chambers can be produced as small as 35cc, ports anywhere from 180cc to 280cc. The head will feature newer more efficient 3V port and high swirl combustion chamber designs. However, there is enough material in my port & chamber to CNC finish to a standard Ford 4v port, I'll have a 4v CNC port program underway for the die hard 4V enthusiasts, however the 4V head will retain a modern combustion chamber so if you're after a straight head swap with high compression (i.e. pop-up dome) pistons it ain't going to work unless you change the pistons.

Scott Cook

Tod Buttermore also announced he's beginning production of his new block today. So we now have a stock looking heavy duty block available in either aluminum or iron, and a stock looking alloy head available with 3V or 4V ports. No more waiting, the future has arrived. The Cleveland made more horsepower per cubic inch, naturally aspirated, fueled by gasoline, than any mass produced OHV engine. It is back with a vengeance. This is an amazing day for enthusiasts of the Cleveland engine.

-G

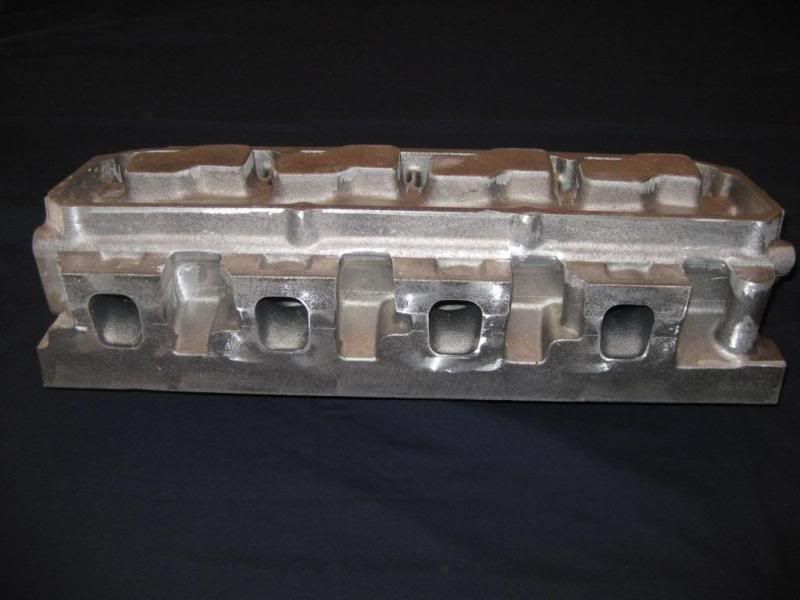

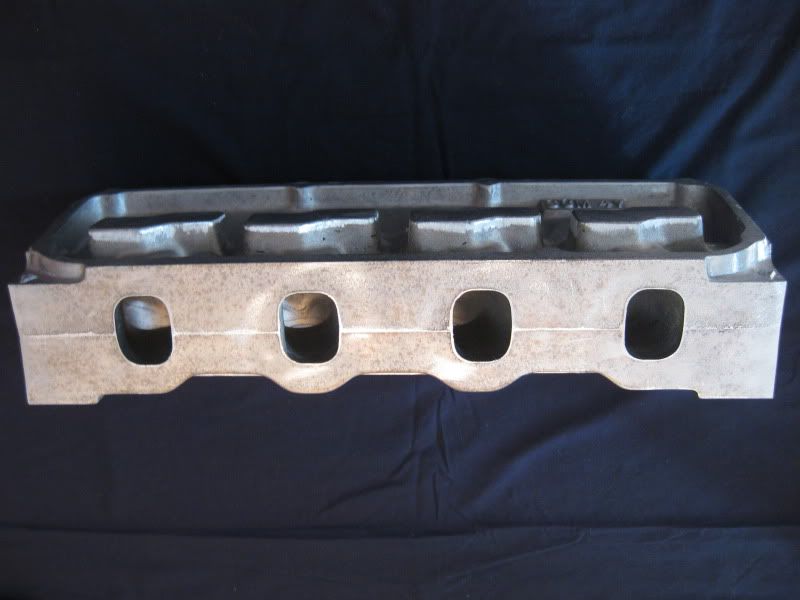

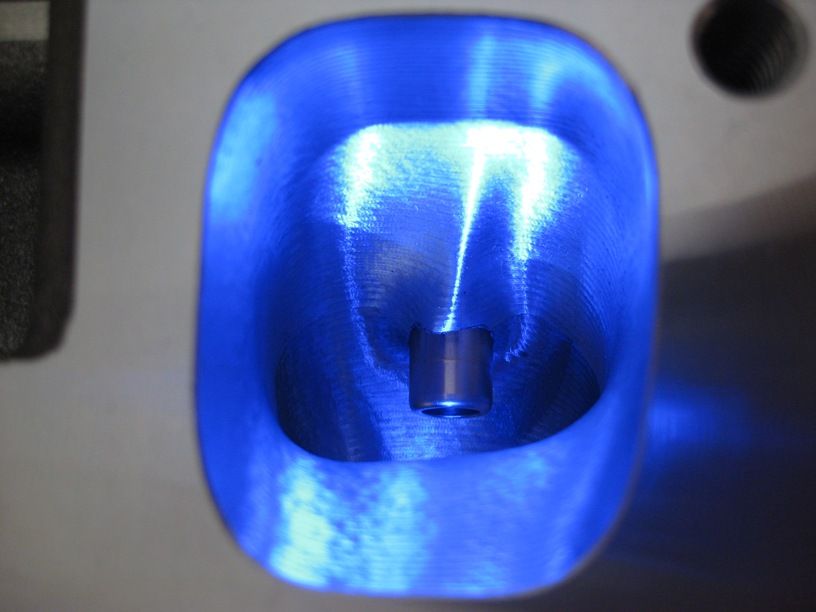

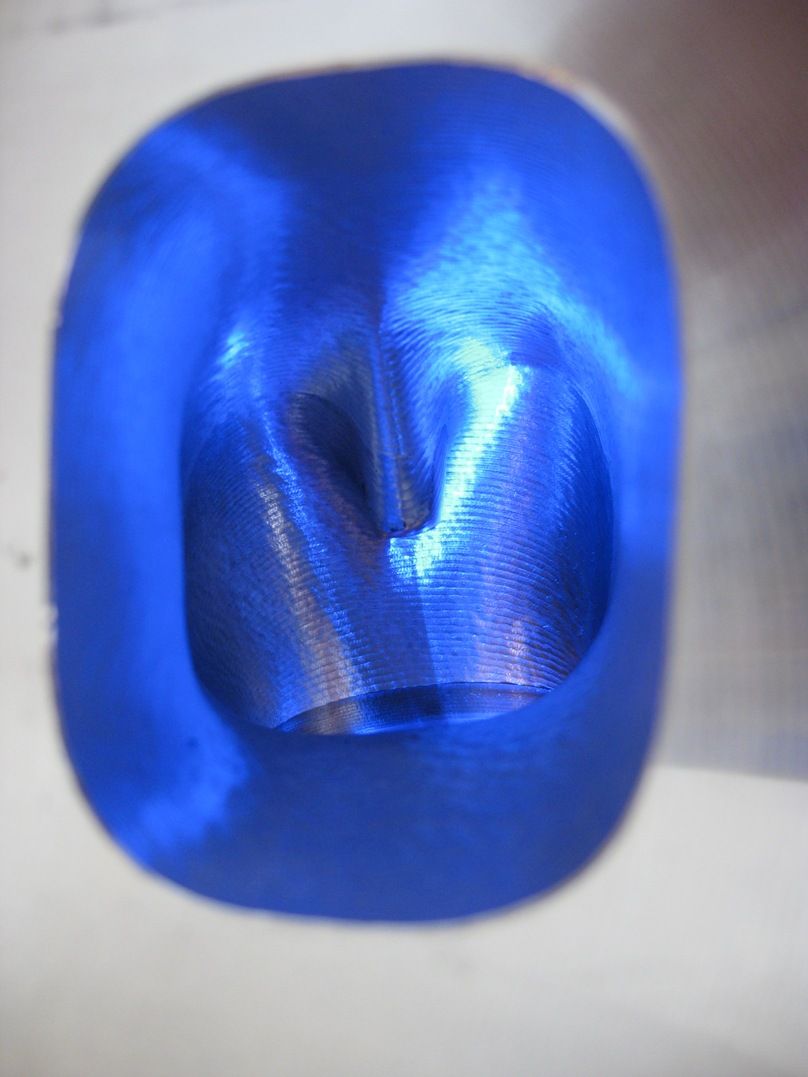

FYI: Pictured below is Scott Cook's two plane aluminum intake manifold for 3V heads.

It is externally identical to a Ford D0AE-L iron manifold.