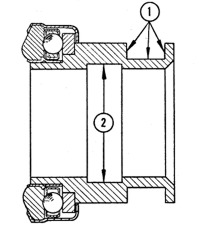

This is a cautionary tale,I replaced my expensive throw out bearing that matches my twin disc clutch about 20 miles ago, just cause I had the engine out for a oil leak repair ( and transmission rebuild ). The clutch operation was smooth and felt normal. after hitting 2nd and rolling to a stop, I suddenly could not push in the clutch pedal? Hear are the pictures of the failure.

Attachments

Original Post