There are 3 lifter diameters in the hot rod world ... General Motors is the smallest at 0.842" OD, Ford is in the middle at 0.875" OD and Chrysler/AMC are the largest at 0.903" OD. Generic camshaft lobes must default to the lift rates allowable with General Motors lifters. It is obviously advantageous for Ford guys to have camshafts ground with lobes designed specifically for Ford lifters. This is one of the reasons why custom ground cams can sometimes beat the pants off an off-the-shelf cam.

Within the limits of a hi-performance 351C 4V street motor or sports car motor all I need is 3 hydraulic flat tappet cam lobes to allow me to grind a good selection of camshafts. They need to be "rpm" lobes, which means the lobes are designed for high ratio (1.73:1) rocker arms and/or high rpm. Here's my list of lobes:

(1) 275° advertised duration, 225° duration @ 0.050, 0.570" theoretical lift

(2) 280° advertised duration, 230° duration @ 0.050, 0.580" theoretical lift

(3) 285° advertised duration, 235° duration @ 0.050, 0.580" theoretical lift

These 3 hydraulic lobes represent real world lift rates attainable with Ford hydraulic flat lifters, but not with GM lifters. These lobes cannot be duplicated with a hydraulic roller cam either. A hydraulic roller cam with equivalent duration at 0.050" will have greater advertised duration and therefore more overlap for any given lobe separation angle.

These lobes are similar to the lobes designed for Lunati's VooDoo cams or Comp Cams Extreme Energy cams. They allow more "area under the curve" (what I was taught to call "the window") for a given amount of overlap, and also allow closer to optimum lobe separation angles for a given amount of duration at 0.050". The result for you and me is less trade offs in a street motor in terms of horsepower output, drivability and powerband characteristics.

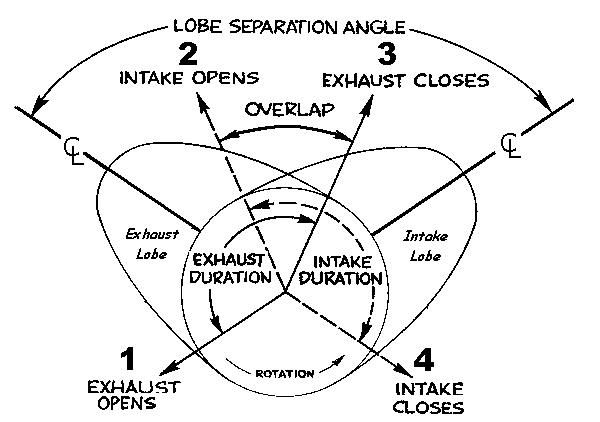

Duration at 0.050" and lift are good numbers for comparing the "area under the curve"; they give us an idea what the ultimate performance in terms of horsepower a particular cam may impart to a motor. But advertised duration is the data I use when describing overlap and intake valve closing, as this seems to more accurately predict what an engine's powerband will be. I believe overlap for 351C 4V street cams should be conservative, in the range of 50° to 62°, due to the large canted valves pointing toward one another. For reference the Cobra Jet cam had 47° of overlap, the Boss 351 cam had 58° of overlap. Intake valve closing is important as well, close it too early and a motor will not rev very well, close it too late and it will impact idle and drivability characteristics. Ideally the intake valve closing point should complement the amount of overlap in tailoring a motor's powerband. The cobra jet cam closed its intake valve at 72° ABDC, the Boss 351 cam closed its intake valve at 76° ABDC. Motors with high velocity ports can close the intake valves later, because reversion occurs at higher rpm due to the velocity of the air flowing past the intake valve. The 351C 4V is not such a motor.

_____________________________

Those 3 lobes I described allow me to grind 4 cams:

Cam #1 is a tire frying daily driver with better drivability (less overlap) than cam #2

275°/275° advertised duration

225°/225° duration @ 0.050

0.570"/0.570" theoretical lift

110° lobe separation angle

55° overlap

Intake valve closing at ~66° ABDC

Cam #2 and cam #3 are the same cams from the standpoint of powerband, but they are intended for cars with two different exhaust systems.

Cam #2 for cars with a restrictive exhaust system (dual pattern cam)

275°/285° advertised duration

225°/235° duration @ 0.050

0.570"/0.580" theoretical lift

110° lobe separation angle

60° overlap

Intake valve closing at ~72° ABDC

Cam #3 for cars with a performance exhaust system (single pattern cam)

280°/280° advertised duration

230°/230° duration @ 0.050

0.580"/0.580" theoretical lift

110° lobe separation angle

60° overlap

Intake valve closing at ~72° ABDC

Cam #2 ~425 BHP, cam #3 ~450 BHP; about the best you're gonna do with that much area under the intake curve, and that much overlap. I'm assuming ported 4V heads, 10.0:1 compression, 750 Holley jug, Shelby/Blue Thunder manifold.

Wanna make it "pop" a little harder ... squeeze the lobes together (more overlap). Better have a good exhaust system for tighter lobes, so you're more likely to do this with cam #3.

Wanna mellow it out .... spread the lobes apart (less overlap)

You can emphasize the low end of the powerband by advancing the cam (Intake valve closing at ~66° ABDC)

You can emphasize the upper end of the powerband (more over-rev) by retarding the cam (Intake valve closing at ~76° ABDC)

Cam #4 is a super-hot, rough idling cam with the most overlap I recommend for the street

285°/285° advertised duration

235°/235° duration @ 0.050

0.580"/0.580" theoretical lift

110° lobe separation angle

65° overlap

Intake valve closing at ~76° ABDC

_____________________________

At this time I am aware of one such lobe in the Bullet Cams catalog, it falls in the middle of lobes #1 and #2 in my list. Bullet Cams lobe #HF277/335. A hydraulic flat tappet asymmetric RPM lobe, designed for 0.875 OD lifters (Fords).

If we grind cam #3 using this lobe, here's the cam we end up with.

277°/277° advertised duration

228°/228° duration @ 0.050

0.579"/0.579" theoretical lift

110° lobe separation angle

57° overlap

Notice this hydraulic flat tappet cam has 0.579" lift with 1.73:1 rocker arm ratio. That's only 0.012" less lift than the Corvette LS7 hydraulic roller cam, which uses 1.8:1 ratio rocker arms! You can't do this with a hydraulic flat tappet lobe designed for Chevy lifters.

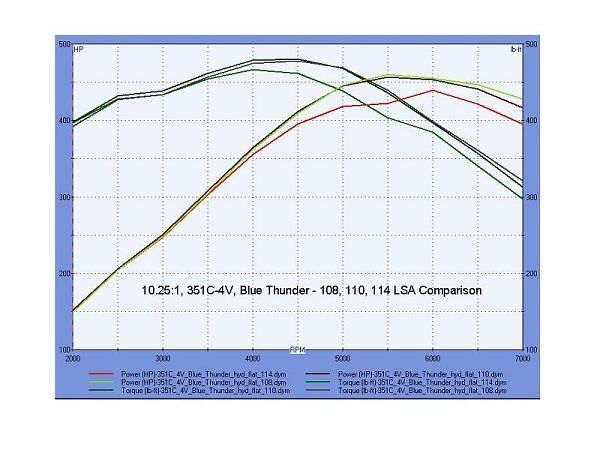

Dan Jones ran this data on his desk top dyno. I am assuming he ran this data with the advanced timing (intake closing ~66° ABDC). He didn't actually say and I forgot to ask.

This little hydraulic flat tappet cam made 460 BHP at only 5500 rpm with good over-rev to about 6500 rpm on Dan's desk top dyno. It made 400 BHP at 4400 rpm, and was still making 440 BHP at 6500 rpm! Now look at the torque curve! 400 ft/lbs or better from 2000 to 6000 rpm. Nice.....

I expect this cam to pull harder on top, to peak at higher rpm, if the timing were retarded. (gain ~10 BHP at 6500 rpm)

The overlap is only 57°. The Boss 351 had 58° overlap (but the Boss 351 cam employed a power robbing 116° lobe separation angle).

Hows that for a streetable 460 BHP cam that doesn't require lash adjustment? Its got the factory Cobra Jet and Boss cams beat by about 75 to 100 BHP, yet it doesn't resort to excessively high valve lifts, its just a good ol' reliable, unassuming hydraulic flat lifter camshaft.

-G