I finally got my engine back from the builder and I'm trying to come up with a breather/ PCV set up. I know this has been discussed in the past and the consensus was that it's best to use a PCV valve.

The valve covers I have are the twist in type and I could even use the stock Ford oil cap if I wanted to. There doesn't seem to be much choice in twist in type breathers and I couldn't find any that have a PCV valve.

I found Ford Racing grommets (M6892F) that allow the use of a push in type breather in a twist in type valve cover. The set of grommets come with one to fit a breather and one that fits the stock PCV valve.

I bought some Billet Specialties push in breathers (one breather and one with PCV valve). The breather has a 3/8" hose barb which would be perfect to attach a hose to the 3/8" tube at the base of the Holley double pumper.

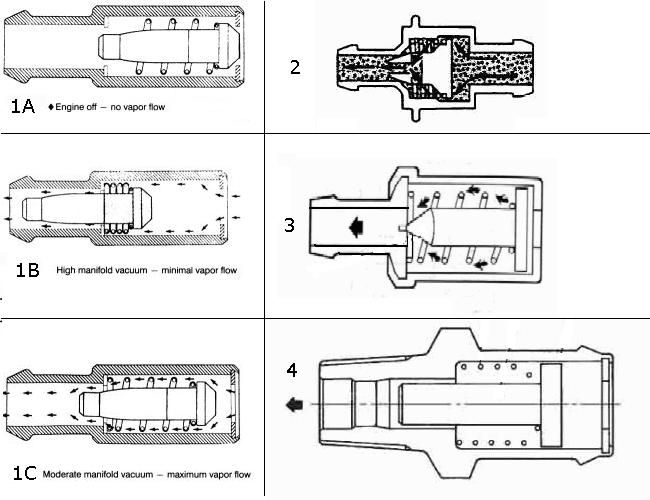

My question is, will this arrangement work good enough? The Billet Specialties uses a Fram FV181 valve, which I believe is used for Ford inline 6, 302, and maybe 351W. The diameter is smaller than the stock 351C. The only other option I see would be to use the Ford Racing grommet that fits the 351C PCV valve, but that has a 1/2" hose attached to it and how would I connect that to the 3/8" Holley tube?

I would love to hear what you guys are successfully running. Oh, and a big thank you to all of you who gave me advice on selecting parts for my engine build. It turned out better than expected and really "rocked" and "rolled" on the dyno.

Dennis

Attachments

Original Post