I believe when the Pantera's cooling system was initially designed it was intended by its designer to have a functional swirl pot and a header tank. The header tank is needed anytime the ability to vent air is needed in a cooling system. Without a header tank a swirl pot cannot function, and a radiator vent has nowhere to vent into. Obviously somebody altered the design before the Pantera began mass production. However, because the Pantera's cooling system tanks were intended to be a functional swirl pot and a header tank, it is very easy to alter them and make them functional.

The Pantera's radiator vent has never functioned, and the Pantera has always had a problem with air trapped in the radiator. Air trapped in the radiator is the Panteras second biggest cooling system problem, next to the wrong thermostat being installed in the motor.

I had intended to fully modify the cooling system in my Pantera, turning it into a high flow style cooling system. But after I realized what the real problem was, I decided to go a different route. I decided to simply modify the tanks to restore their originally inteneded functionality, thereby allowing the radiator to self purge continuously. Coupled with a good radiator and a pair of good fans, I believe this is all that is needed for a Pantera to have a top performing cooling system.

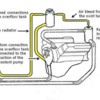

Here's the basic drawing of the modification.

Attachments

Original Post