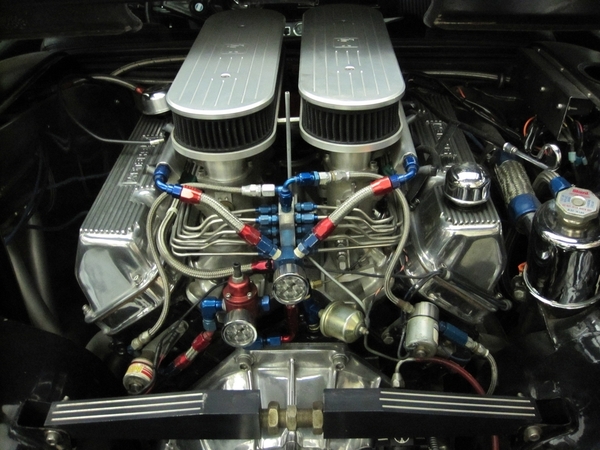

There has been significant development in aftermarket EFI kits since the "Blue Pantera" was built.

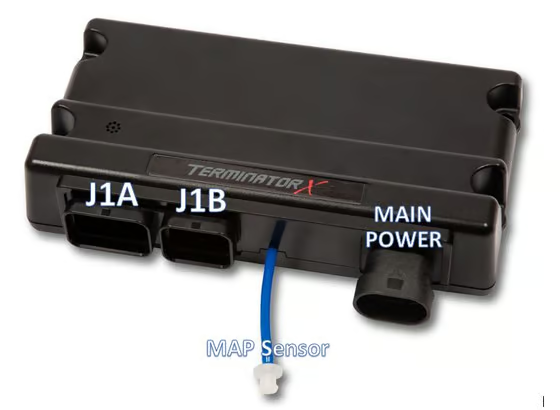

The Holley Terminator is Holley's solution. Edelbrock has one also called the FAST system.

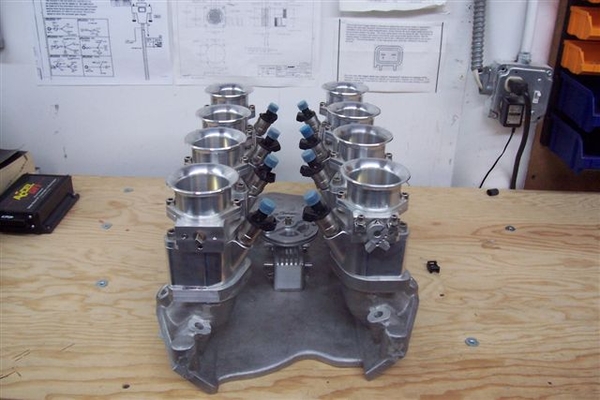

I have the same eight stack system being talked about here and I am using the FAST. It is self learning. Plug and Play. It is about as simple and uncomplicated as these aftermarket systems are about ever to be.

You can easily go into the software charts and change the parameters but it isn't necessary. The software is already set to modify itself to achieve specific a/f points that have been dyno proven. You can change them if you want but so far from what I am seeing, it isn't necessary.

The set data is smarter then you are and the cpu is a lot faster at making the right changes then you can.

Also, FAST (Edelbrock) was wise enough to use very common (and inexpensive to replace) sensors in their system. That is a big plus for maintenance costs and longevity of availability of those components. There are no components shared with NASA, Ferrari, Porsche or Lamborghini. Just plain Jane GM production vehicles that will have service parts around for some time to come.

The FAST does use a MAP sensor to measure engine load. So it needs a common plenum chamber with all eight throttle throats plumbed to it, in a manner as if you were plumbing in a vacuum gauge.

Essentially that is what the MAP sensor is doing. Reading engine vacuum.

It should also be pointed out at this point, that the "vacuum gauge plumbing" does not need to be plumbed individually, each runner with a separate tube to the common vacuum box that you use. It works fine being plumbed in series, i.e., like Christmas Tree light wiring. Each line plugged into the other. That makes it much easier and cleaner to do on any car, particularly on a Pantera.

Theoretically, that Haltech is kind of obsolete now. It had to be programmed with a lap top for virtually everything.

It's main advantage at the time was thought to be that it fires the fuel injectors individually like an original equipment efi system does on a new vehicle.

For aftermarket uses, that is really not necessary and over complicates the programming unnecessarily.

FAST uses a batch fire system. It fires four fuel injectors at a time x 2.

The only disadvantage to that, if it is a disadvantage, is that for emissions reasons, you will have a minutely dirtier exhaust test.

That is because for a microsecond, there is unburned fuel laying on three other intake valves which haven't opened on the intake stroke yet and that unburned fuel can migrate to the exhaust valve in certain cam timing sequences.

So, therefore, individually fired fuel injectors are cleaner at idle and with US Emission standards, new vehicle manufacturers need every advantage they can get. That is why all OEM fuel injection systems fire the fuel injectors individually instead of in batches.

On a vehicle like the Pantera that is way over 20 years old, in the US, that simply isn't necessary. Batch fire is absolutely fine and as I see it, preferable?

The batch fire system that FAST adopted was actually designed by Bosch. It isn't a haphazard design. Just not optimal for new vehicles with strictly controlled exhaust emission requirements.

Performance wise, i.e., maximum power/go fast, there is no difference between individually fired and batch fired systems. At some point around 3,000 engine rpm's the individually fired fuel injectors can not keep up and start to work as a batch fire system.

So really those are the differences in the two available aftermarket EFI designed systems right now.

I have heard from certain self qualifying experts that they wouldn't be caught dead using a batch fire simply because it is the older design and not sophisticated enough for them to put their stamp of approval on it. So be it.

I don't argue. NO ONE is perfect! I realize that even if they don't. Sometimes very "bright" people can be very difficult to live with. I try to give them space.

The fact of the matter is that all things being equal, the simpler system by definition has to be better.

Anyway, that's what I know about what is going on with converting to EFI INDIVDUAL RUNNER aftermarket right now for whatever that is worth.

Again, the technology has just changed significantly within the last few years and those old systems like the Haltec are now just historical markers in the progression of better technology.

I'm just trying to help and sometimes the simplest things need to be stated. I'm not highly intelligent, just highly experienced.