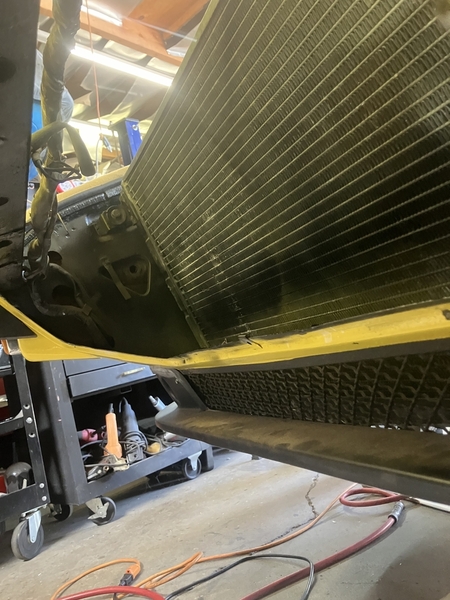

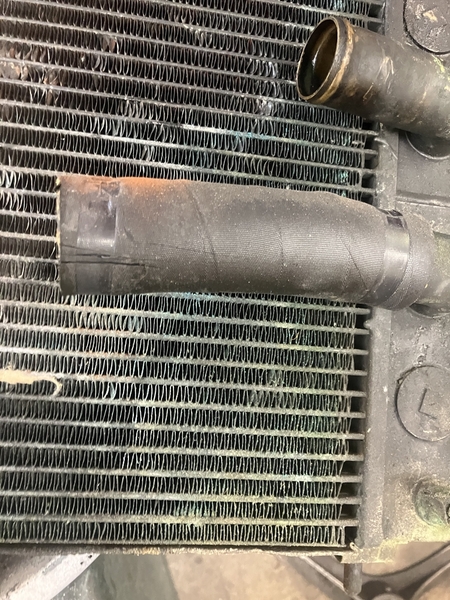

At the fist glance my cooling system looked pretty good… just peeking under the car with the flashlight when I bought the car… nice silver coolant tubes running along the bottom of the car… stainless steel already? - great! Radiator from the front and top.. black.. all straight!! Cool!! BUT: starting to tackle my electric issues I unbolted the inner fender off the right front fender facing the front … and what I saw was not pretty: the area on the bottom right of the radiator is green - leakage for sure…! As I was working on my brakes I was under the car and I discovered that the water pipes were painted silver, a bit deceiving for sure! Leak marks around the rubber connections …. Well, oh well… here is the next project !

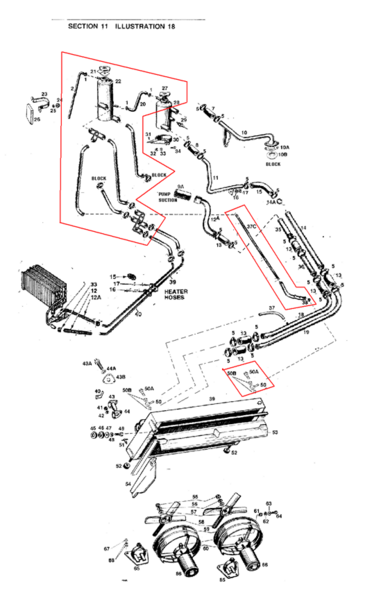

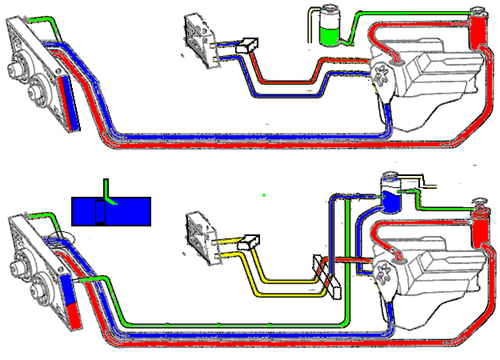

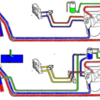

I’m going for the whole 9 yards! Aluminum radiator leaning more forward, sucker fans, stainless steel tubes, new rubber hoses, water pump thermostat…

Because there is another project and thread attached to this one ( “heater core - keeping cozy”) and I would like to have some help with this I send my car to PIM on Friday and I will be there on Monday after dropping the kids of and with the help of Hans it should be not to bad…

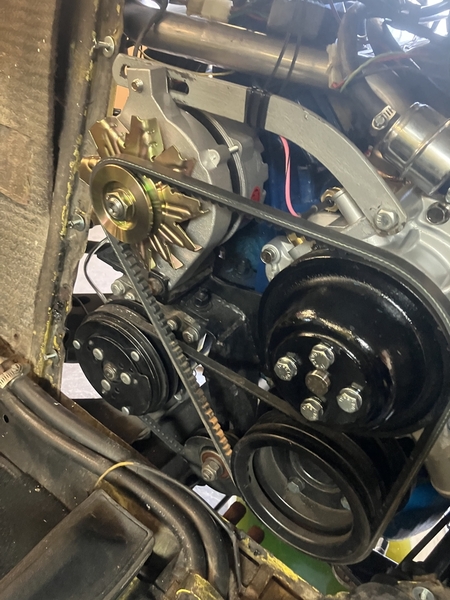

Gear is ready to fall apart…

Gear is ready to fall apart…