Purchased new struts for the deck lid from McMaster Carr corrosion resistant gas spring, 15.53" Extended 110 lbs extension force. They have 6mm threaded ends that are perfect for what I have on the old struts. They work great, I have an Amerisport wing (not the Delta wing), these struts lift the deck lid very smoothly.

Replies sorted oldest to newest

And the chrome look is a great touch!

I like it!! After 50 years my original struts have retired from working. I’d like to get a pair. Like MJ, I too would like the part number. Thanks. Joe

Also, how much do they cost?

Thanks for sharing this!

That’s great! Thanks!

Everyone should be aware and take note that he is using the struts for a decklid that has a delta wing.

strong enough for the Delta wing may be too strong without the Delta wing. There are cases of struts with excessive force bending sheet-metal around the deck lid hinges.

this is a recurring topic and a search of the archives might find a post giving recommended pounds of pressure for wing and no wing cars.

Larry

There is an additional engineering consideration that needs to be considered here on replacement struts and ultimately is a factor in the early or very early demise of the struts.

That factor is the operating temperature the strut is designed for.

There are MANY struts that on paper work very well BUT few IF ANY are rated for operating temperatures in the engine compartment.

In stock form the exhaust manifolds seem to be far enough away from the struts but for example, in my case with 180° headers, there are only a couple of inches clearance to the headers.

The o-ring seals in these struts are not designed to take that kind of heat in addition to boiling the cylinder fluid or gas.

IF you find that page in the specs, which sometimes takes some doing, you will find that many are going to be limited to under 200° F. This is your major limiting factor.

So really those struts that you found need to be field tested but I suspect that they won't last any longer then the conventional deck lid struts do, which isn't very long at all.

Doug, these struts are only rated to 176° but it should be noted they are made from stainless steel, which should help with the heat issue you mentioned.

@davidnunn posted:Doug, these struts are only rated to 176° but it should be noted they are made from stainless steel, which should help with the heat issue you mentioned.

Stainless won't melt at that temp but the o-rings will be on borrowed time.

Put your oven thermometer in there. See what it reads.

Those are likely marine applications for covers on cargo boxes. Let's understand the main issue here. That being is there are no lifts made with the heat rating needed.

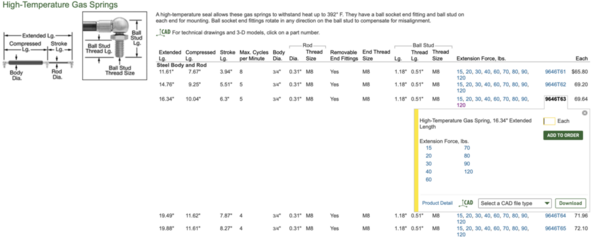

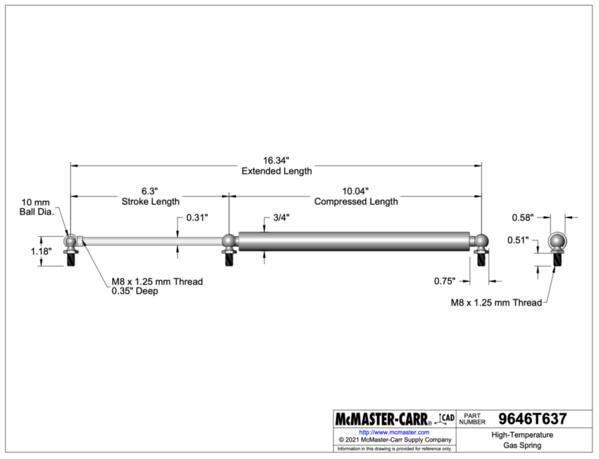

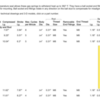

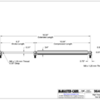

FWIW, McMaster-Carr does list gas springs that are rated at 392°F. Unfortunately, the only ones that they list have ball stud ends with no info as to whether or not the ends unscrew from the shaft and body, and the extension force jumps from 90 to 120 lbs. ![]()

John

Attachments

I previously bought these and am happy with them however I do not have a wing.

@lousbby posted:I previously bought these and am happy with them however I do not have a wing.

I bought those. They lasted about 3 months.

@panteradoug posted:I bought those. They lasted about 3 months.

Sorry to hear that, mine have been in my car since 2001 and they still work.

I read all the replies, so what are force requirements for a non wing deck lid and a wing deck lid?.

@jb1490 posted:

Specs like how the ends are attached are not often given. I would speculate that those are threaded connections rather then welded. If they are welded, then they probably are friction welded.

Conversely if threaded then a Pantera friendly end can be attached.

In this case you won't know until you have one in your possession?

The higher temperature rating is something to be desired though.

I've got 180° headers on the car. I have only about 2" clearance to the header tubes which is definitely the key factor for me.

So far I have not found a long term solution.

I’m on my second set of the standard McMaster-Carr gas springs. The first set were 80# but I felt them to be a little weak, especially when it was cold. When I bought the second set I went with 90#.

Based on the drawings above the standard has a 6m thread on the ends and the high temp version have a 8m thread. The next set I buy I will consider the high temp.

Steve

@johrt posted:I read all the replies, so what are force requirements for a non wing deck lid and a wing deck lid?.

If I recall 110 lb for wing and 90 lb without, but the crux of the issue is that the factory fulcrum point puts unnecessary stress on the decklid close to the hinge point. The IPSCO solution to relocate the mount points is the best IMO.

https://ipsco.org/newsite/prod...ock-replacement-kit/

Ted Mitchell at Vadar Racing used to sell a spring solution.

I have a standard decklid (no wing). The first replacement strut came from one of our vendors and was rated at 120 lbs. I quickly discovered that I had to hang on to the decklid until it was fully open. If I let go, it would "slam" open. Not a good thing. I never had any issues with the hinges or the structure.

When one of those struts died, I found a supplier near me that let me try different spring ratings. I tried a 90 lb first. The decklid was much easier to "handle" than the 120 lb struts. With the decklid fully open, I hooked a spring scale (luggage scale) to the decklid latch and measured 7 lbs initial force to start the decklid moving. I really liked the 90 lb struts, but a light gust of wind would slam the decklid shut.

Next, I tried the 100 lb struts. These made the decklid "feel" heavier, but not as heavy as the 120 lb struts. With the decklid fully opened, I measured the breakaway force at 15 lbs. That appeared to be a good number to counter moderate wind gusts. What I really liked about these struts is that they have a "soft open" feature, meaning that the opening rate slows as the strut reaches full extension. That feature allows me to open the decklid part way and let go of it. No more having to hang on to the decklid until it is fully open.

YMMV

John

In case not everyone here knows, Jon Haas, aka, Pantera-Electronics makes a power operated decklid kit.

It works like a current van does. Push a button and it opens automatically.

For those worried about heat, I was tired of changing my struts regular which is challenging enough with a one man job. So I decided to try some heat shield (from Jegs or Summit I believe) around the thick part of the struts and wrapped that in insulation foam and I install them whenever I go for a run. The outer foam tube just helps keep the heat shield material in place, fits nice. Maybe even heat shield wrapped with correct diameter hose could work too. I decided to try this once I noticed I couldn't even touch my struts after a run. Once I stop from a run for a show or whatever I just remove them. Yes they are still pretty warm but not like toast without them. My new struts have lasted for several years, so far so good.

Attachments

As Larry mentioned, most Pantera specialty shops will not sell decklid opening struts of over 110-lb strength, no matter what you've loaded on it. The monococque sheet metal surrounding the hinges WILL wrinkle over time, and fixing those body panels is far beyond almost all owner's capability. Bondo won't work!

Conversely, using a lightweight fiberglas/carbon-fiber/aluminum decklid really requires only one strut to open.