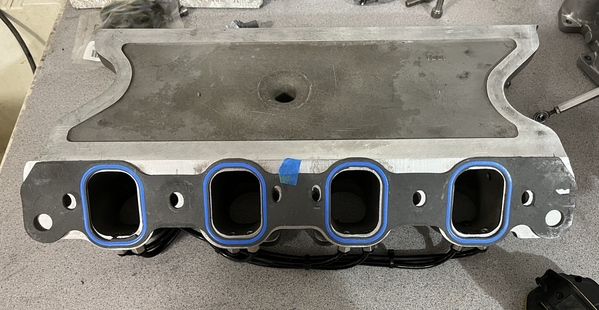

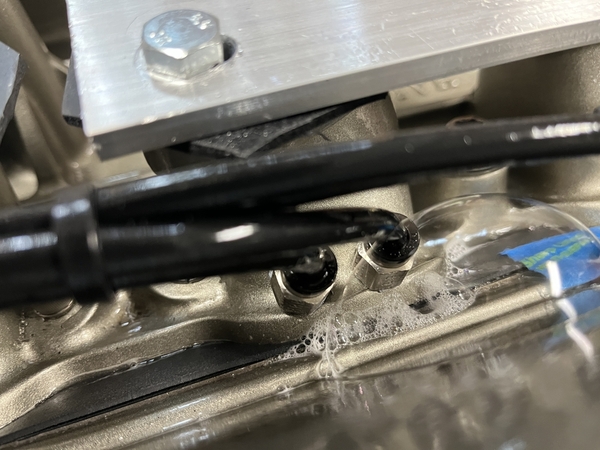

I am nearing final assembly of the engine for my Pantera project that I received in February. I had to do a lot of plumbing for the EFI's MAP sensor and IAC (idle air control) and wanted to test all of that before final engine assembly. Without lifters in the engine, I capped off the Weber intake runners with aluminum plate and rubber sheet, and then used about 30 PSI compressed air to pressurize the intake. I sprayed soapy water and looked for bubbles around my plumbing. There were none and the test was a success. I had already done some testing along the way.

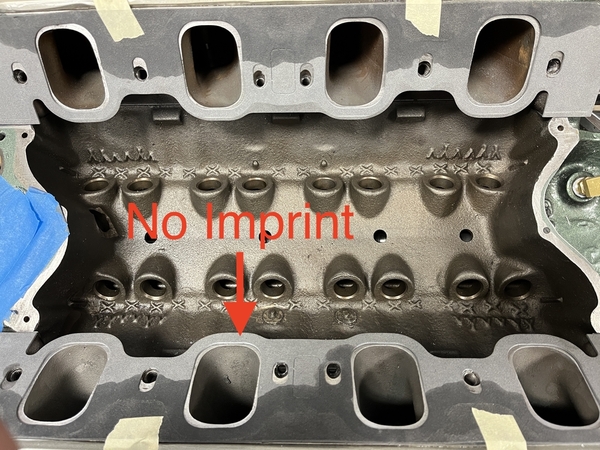

What did fail is the intake gaskets.

I did the above the above test twice. First with Right Stuff seal on back side of the gaskets and I got lots of soapy bubbles along the gaskets. I disassembled it and added sealant to the front side of the gaskets, and reassembled. This time I got a lot less bubbles, but the gaskets did not hold pressure.

On my other Pantera I have had intake gasket leaks where it produced a lot of blue smoke. I eventually put sealant on both sides of the gaskets and that fixed it. But there is no way to know that it is genuinely sealed 100%. After today's pressure test I am starting to wonder if the intake gaskets ever really seal on our engines. What is your experience with these gaskets?

Photos below show the plumbing I was testing.