quote:

Originally posted by Bosswrench:

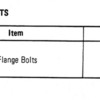

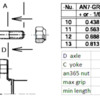

...the 16 bolts MUST be unthreaded-shank 11 mm

or unthreaded-shank SAE 5/8" gr-5 bolts on later ones.

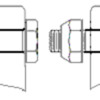

I took thicknes measurements on by axle flange, and half shaft flanges. (I don't have the ZF flange)

the axle flange was ~0.32"

one end half shaft ~0.23"

thus total thicknes of 0.55"

for an untread shank of 11mm (0.43") removing the split washer would be OK

for an untreated shank of 5/8 (0.63) the split washers thicknes of ~0.1" is needed (still too close for me)

the linked thread recomend AN7-11, which has untreaded shank of 9/16 (0.56") and a split washer is also needed.

something I didn't expect to find was that for the one half shaft I dugout to measure, the two end flanges were differnt thickness. One was ~0.23 and the other 0.35". sure wish I knew the ZF flange thickness.

AND, I had an assortment of untreaded shank and full thread bolts with washers.

edit

I look again and determined the yoke flange that bolted to the axle was the thicker, thus for my axle flange