Freddie, the gearbox is cast aluminum and can be TIG-welded by someone in your area. The bad news is, you must remove the whole transaxle (it weighs 155 lbs), drain it of lube that will otherwise catch fire, and take it to a welder; TIG or heliarc welders are not portable.

Once the case is rewelded, the bolt hole probably will need to be surfaced and rethreaded, so maybe a machinest should also be consulted. I would try 'JB-Weld'- an economical aluminum/epoxy material first, as JT suggested.

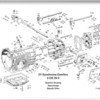

You have damaged possibly THE most expensive single part of your car. A completely rebuilt ZF dash-2 transaxle, using all-new parts from RBT Transmissions in the Los Angeles area of the U.S.

www.rbttrans.com, will cost roughly $10,000 USD. And you pay shipping both ways. Used assemblies of unknown quality cost $5500-up. Which is why I suggest a welder and machinest local to your area be contacted, or try the epoxy.

RBT is the owner of this design of ZF, having bought the rights, tooling and all spares from the German company some 30 years ago. There are no other sources of new parts, although good used parts can sometimes be found. Good luck.