Mike,

I wanna say that somewhere under or around 2 gallons of antifreeze does the trick.....mixed from 33-50% with water for conditions..... if not enuf, then simply add more water. Should put you darn near there......hoses, tubing, overflow tank, which radiator....engine doesn't hold all that much in the big picture.....

I think the whole system used right about 2 gallons of fluids....was surprised at how much it didn't take!

If or when I had too much mixed up, it just goes on the shelf with a tag that says MIXED @ xx%. Generally used the same coolant in another vehicle(s) so came in handy!

If you predrilled your t-stat with a little 1/8" hole at the top somewhere, you can fill the car level and the engine will self bleed! Depending on radiator you may have bleed caps to pull/remove, or a valve.... I also had a bleed screw on a fitting on my small 90 degree pipe that went to the lower tube.

Easier to use bleed screws in the necessary places than go jacking up the car here and there.......to try and get air bubbles out of the engine!

Since you mentioned the T-stat thing......slightly related notes.....

There were two versions of the 90 degree intake water pipe. Early cars had no threaded provision for what I believe could have been a vacuum 3-port temp operated switch/valve, which connected to the full vacuum at the intake, ported vacuum at the carb, and the third went to the distributor vacuum port! Was a feature for AC cars........ (pic of new #898 stainless fab'd piece (no port) on bottom, orig ported on top!)

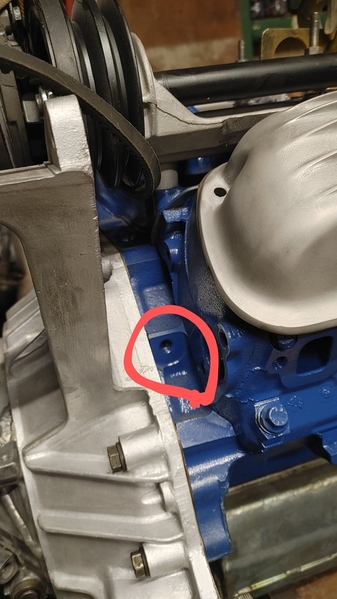

You can see port in intake here, with brass reducer/adapter for bleeder valve. Port on 90degree pipe just to the right.

Front view of bleeder valve installed on pipe after some paint! #878

The later cars got the ported pipes! As you can see in the above 3rd pic and below, that I didn't run this vacuum switch in my car but rather a bleed valve......there was a port on the intake, just to the aft of the bleed valve, for the temp sender, as I did not use the vacuum advance but rather ran it as a mechanical only advance distributor with a whole lot of initial advance... with the DuraSpark II ignition system.

The later cars got the ported pipes! As you can see in the above 3rd pic and below, that I didn't run this vacuum switch in my car but rather a bleed valve......there was a port on the intake, just to the aft of the bleed valve, for the temp sender, as I did not use the vacuum advance but rather ran it as a mechanical only advance distributor with a whole lot of initial advance... with the DuraSpark II ignition system.

Tubes and hoses connected.

Front view of Y-pipe & various connections. Short 2" or so piece of black hose near the bottom of the Y-pipe was for a vibration potential with something that I do not recall!

Note that the long oil sender extension used to put oil sender where it is sitting in above pic, was not stock to DeTomaso, but rather to Mustang/Cougar and most all other Fords of the time! This long one didn't fit properly...oil sender hit the frame(!) and I don't know where the original short one went......! It was a cut down long one....likely by DeT production folks! I ended up installing a "Boss 302 oil sender relocation kit" Pricey, but worked perfectly!

That was a long answer to your question!

Cheers!

Steve

The later cars got the ported pipes! As you can see in the above 3rd pic and below, that I didn't run this vacuum switch in my car but rather a bleed valve......there was a port on the intake, just to the aft of the bleed valve, for the temp sender, as I did not use the vacuum advance but rather ran it as a mechanical only advance distributor with a whole lot of initial advance... with the DuraSpark II ignition system.

The later cars got the ported pipes! As you can see in the above 3rd pic and below, that I didn't run this vacuum switch in my car but rather a bleed valve......there was a port on the intake, just to the aft of the bleed valve, for the temp sender, as I did not use the vacuum advance but rather ran it as a mechanical only advance distributor with a whole lot of initial advance... with the DuraSpark II ignition system.