quote:

Originally posted by pantera chris: I was very surprised by your experience, I have a twin disc clutch, master on my bike and a proportioning valve on the Pantera as well, the tec service I had was exceptional and they are very familiar with our cars?

Not sure if you are referring to the McLeod hydraulic slave or just their products in general. My comments were in regard to the McLeod (slave cylinder not master) TOB in the link the Original Poster posted, and perhaps they were having a bad day, but it actually was three bad days over the course of 3 weeks because that’s how many separate calls and iterations it took.

As I mentioned I phoned to speak with them about their kit and got the usual assurances but they would not sell to me direct and referred me to Jegs and Summit with a part number. When it came there was no spacer included in the kit. After a few futile phone calls with Scummit they sent me back to McLeod. McLeod said was oversight. –OK Fair enough; it happens. They sent one to me. It was the wrong spacer. When I called them and explained the problem, they sent me another one…….the same wrong one and they either had ignored the conversation or they had a stock of incorrect parts under the ZF spacer part number! When I called and emailed pictures of the problem they told me they had never had a complaint and couldn’t help me…….I had already concluded the latter by that time.

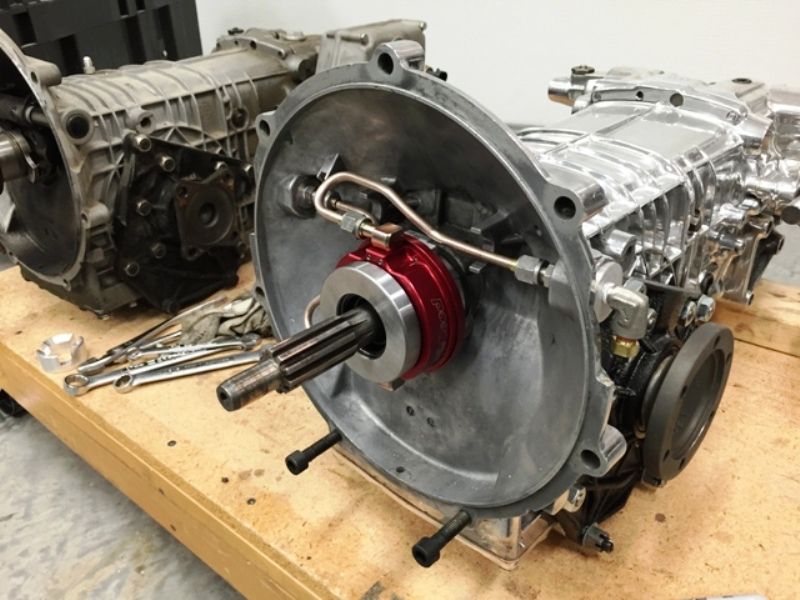

The picture below is the spacer they sent me (twice).

The problem is obvious right? The slots were clocked improperly to clear the bolts on the ZF input shaft collar. All ZFs are the same in this regard and the bolt heads are not evenly spaced at 120 degrees apart. It also was the incorrect height, and yes, it was their clutch too. Now I could have just chucked it and turned it to the correct height, and milled the slots wider, but the only thing that made it a Pantera kit over just buying their hydraulic slave was the spacer and two hoses, which by the way were strange lengths and not useful so I tossed them in my used parts stash. Anyway, there were other issues too but it’s all in my little write up, and as I’m sure you can tell, I’m still grumpy about it.

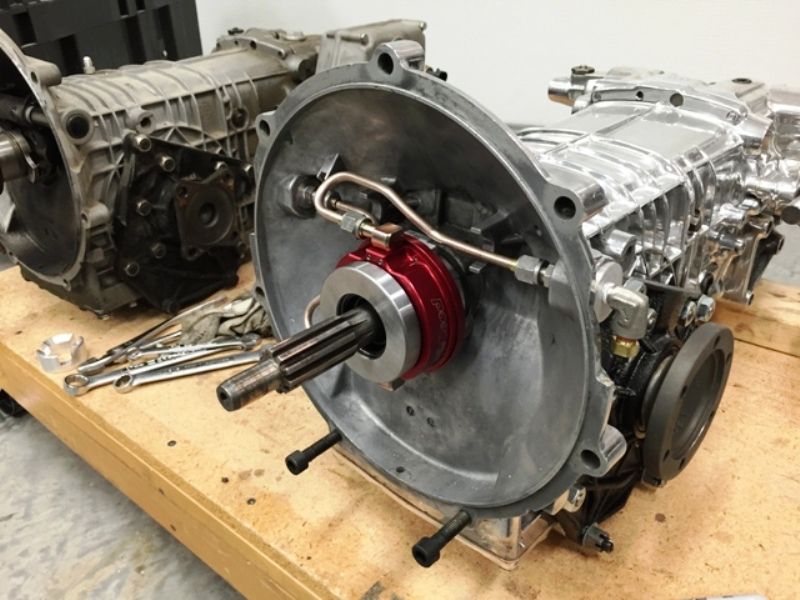

Here’s a picture after my mods and final install.

Here’s another McLeod story. I’ve run street Twins in my cars and Pantera for the last 15 years. Here’s a cut and paste I previously wrote on that experience and a little history on that products evolution. I offer it just in case some else has an old Street Twin, and perhaps to further understand how I’ve formed my opinion. –Better get a cup of coffee.

I bought by first McLeod Twin Disc clutch from Dennis at Pantera Performance in 2001. I also visited the idea of the hydraulic TOB with him at that time but declined. I considered it again around 2003-2004 on another engine build didn’t opt for it because I just couldn’t go away from external access to the slave cylinder…..It’s a lonnnnng story but there may be something to be learned from it so here it goes:

Dennis was working with McLeod to adapt it their street twin to the Pantera around 2000. It required the usual tweaks, just needed to make sure there was no bell interference from the PP and actuation arms, and of course properly engage the TOB. I believe he offered the hydro TOB well before that time. He told me my Twin was one of the first two he had sold for a Pantera. I was a bit hesitant because it was expensive but I was going to buy an aluminum flywheel anyway and Dennis was eager to get a few in the field so he said he’d make it worth my while and I bought it. That was about 2001. It was a very nice piece and quite a bit lighter than my unit at the time, but this is basically all a function of the aluminum flywheel. The engine I had at the time was externally balanced so the aluminum flywheel is too. All my engines since have been internally balanced.

So back in this time, all McLeod Street twins had a proprietary flywheel specific to the Street Twin, and the external balancing was done by slugs pressed into the flywheel instead of bolt on weights that change neutral to whatever balance as in today’s models. The other major difference, at that time, all McLeod street twins had pin drive instead of strapped floater discs they sell now.

I did not do the clutch install as my car was at PPC at the time. When I eventually got the car on the road, initially it ran beautifully, shifted like butter and the clutch held like a vice. However, over time, and I’m talking a few years, the shifting quality began to degrade and it started to hang up. Not bad but you could feel the tension pulling it out of the lower gears and eventually it started clanging the synchros a bit in 2nd and third gear. I was told my ZF might be getting tired but it had just been rebuilt by Butfoy. I noticed when it was cold, it still operated very smoothly but the hotter the day and harder I ran it, the more symptomatic it became. It seemed highly correlated to operating temperature so I removed the bell housing site window cover I had installed and it actually made a noticeable difference in that it took longer to run it to the point where it acted up.

Over time (we’re talking 8 years) it continued to act up occasionally and degrade to the point where last year, if I took it out and ran it very hard on a Summer day, a couple times it got so bad I could not even get reverse or first gear while sitting still. I’d have to shut it down, put it in gear and start the engine with the clutch engaged. Well at this point I’d obviously had enough of it but knew I’d have a go at it during the planned engine swap, thus the current go-around I’m having with the McLeod for the RST install.

So of course over this time I was engaged with Dennis and McLeod multiple times. I got fed a steady diet of the idiot questions; did you bleed your clutch, have you checked your slave and its stroke, have you checked the clearance between discs with a feeler gauge, are you over stroking the master. I had previously checked all those things over and over. Dennis even had me change my CNC master cylinder because he had had some problems with them over the years. I called Mcleod no less than six times over this period, spoke with their experts, and got fed a steady diet of the same idiot treatment by them.

OK, here’s why you read all this. A while after I pulled my engine for this swap, and removed the clutch I eventually took the old clutch apart on the bench and had a close look at it. Remember above when I said the old Twins were pin drive? Well the floater is a Blanchard ground plate about ¼” thick with three ears with holes the pins engage so the floater can slide on them when actuated and transmit torque through the pins which are bolted to the flywheel. Upon closer inspection I notice the drive pins look a bit deformed. They mushroomed a bit under the nut that secures them and the diameter was visually not consistent along their length. So I take one of the pins off to have a closer look and discover they are plastic!!! No kidding...plastic!!! So you have a ¼” thick plate bearing against three ¾” diameter Delran pins to transmit in my case then ~550 ft-lbs. The Twin clutches were rated for much more.

I instantly realize the problem began feeling a bit angry (this seems to be happening more often these days) thinking back to all the conversations I had with the McLeod tech line on the subject over the years. So that night I do some web surfing on a couple gear head websites I frequent, search McLeod Street Twin in those date ranges and easily get many hits with similar problems and complaints about McLeod Street Twin at that time. It turns out McLeod actually recalled them for these very reasons. Now I feel like a dumbsh!t and am also getting more PO’d because McLeod had to have known about this issue all that time I was calling them….is apparently was common knowledge.

So in the middle of the slave cylinder fiasco, I took the opportunity to take this issue up with the same tech guy I dealt with on that matter. I tell him the whole story (except the bit about my discovery upon recent inspection) and ask if he has any idea what may have been causing such a problem. He would only say my clutch was obsolete and all Street Twins now are strapped floaters now not pin drive. So when I told him what I had observed about the drive pins and actually asked if McLeod ever had any problems with Delran drive pins on pin drive Twins, only then does he come clean and explain that McLoeod started selling the pin drive Street Twins with Delran pins because the floater plate would rattle on the steel pins when folks revved the engine with the clutch disengaged. People with street cars complained. The Delran pins solved the noise issue. However, the material properties of the Delran were not able to withstand the contact stressed induced by the floater, a condition which was of course aggravated by elevated temperature. Do you think the floater ever gets hot from clutch friction? This is what led McLeod to develop the strapped floater design.

I asked him if the old Twins performed well with steel pins, if they had any pins, and if so how much they were. He said yes, they performed flawlessly with them, they have them in stock, cost a couple bucks a set, and he would throw a set in with the spacer for my current set up which of course he never did, but I did get them when I got the (wrong) spacer.

So here is the morale of the story. All that time, I was being afflicted and aggravated by a problem well known to McLeod that they would not disclose to me in multiple tech assistance calls, presumably because they didn’t want to warrant their product. The fix was penny parts....I mean three ¾” diameter steel stand-offs with a mounting hole in the middle. I could have made three on the lathe in 15 minutes. Even when I brought it to their attention on the recent debacle, I had to specifically ask about the problem and the Delran pins to get them to acknowledge the issue.

So you may also assume the other moral to the story is I’m a glutton for punishment and why in the Hell would a buy from McLeod again? Answer: I had already made my purchase before discovery of all the above, I want to get my car back together or everything would go back. The products I bought look to be of very nice quality. Their tech support.....well opinions may vary but I think you can guess where I sit on that subject. I certainly hope for them, I’m the exception not the norm.