All,

Replies sorted oldest to newest

Turns out there's at least two sizes that look identical and the wrong one will not bolt up. Hopefully you can provide the old one to Marlin to use as a template.

I believe Steve Wilkinson has them. I thought this was called a "guide tube" for the TO Bearing?

Yes, it is officially a guide tube. Part number 07203A. Or ZF snout. Or bearing carrier sleeve.

I have ordered a used one from Wilkinson at a very reasonable cost of $107.

Larry

Marlin,

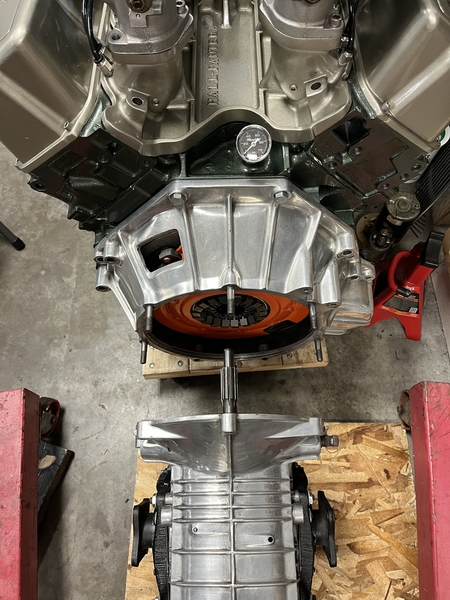

thank you, kind, sir but as I just posted, I found a used one at Wilkinson. The reason for replacement is a mechanical failure that resulted in some binding and subsequent galling of the guide tube and the bearing carrier.

I sent photos to Ron McCall and he suggested I replace both pieces

Larry

Now to explain how this happened.

The black clutch fork is attached to the cross shaft with double split roll pins. One of the center roll pins came loose and was physically touching the inside of the Bell housing.

This was not a factory installed clutch fork. I recently reverted back to the external slave system, retiring my internal hydraulic throwout bearing. Ron McCall said he has never previously seen this failure.

I had noticed during installation one center roll pin seemed a bit loose but dismissed it as unimportant.

Just goes to show the little things DO matter.

🤬☹️

Larry

@rick posted:Turns out there's at least two sizes that look identical and the wrong one will not bolt up. Hopefully you can provide the old one to Marlin to use as a template.

I have been told there is a version for the Pantera ZF and a slightly different version for the M1 ZF.

when ordering my guide tube from Steve he mentioned the guide tube on his new transaxle does not fit the original Pantera ZF.

he made no mention of it being the same as the M1, so now there are likely three versions.

Larry

If I recall correctly, there was a guy on this board called “Mike the Snake” that had the same sort of galling problem.

I’m not sure though how he ever resolved it, Or if it just sold the car. He had a lot of troubles with his car….

I think the post Rocky is referring to is here. "Throwout bearing"

Yep, That’s the one. I got my PanteraChris, and Mike the Snake mixed up!

Thanks!

There are at least 3 ZF configurations, the M1, the Dash 1 and Dash 2. I know the input shaft is different on each of them. I do not know if the guide tube is different x 3 or only x2.

It appears the galling experienced by panteraChris was on a machined steel carrier, same as mine. And I know of another PCNC member who had galling problems, also with the McLeod machined steel bearing carrier.

For comparison, the OEM bearing carrier was machined cast iron and I have never heard of anyone with problems with that metal combination.

does anyone have a galling problem that involved the OEM cast iron carrier?

I am beginning to think that the newer metal bearing carriers have a propensity for galling if there are any mechanical misalignments or lack of adequate lubrication.

Thoughts???

Larry

“The Tribe has Spoken!!!”

(Sorry, couldn’t resist)

Marlin,

thanks for your very kind offer. I will gladly send the old pieces to you for your inspection and amusement.

I know not to use an excessive amount of grease, but I’m now leaning to using Moly assembly lube, which has added graphite.

but I am also going to look into a true Moly grease to see if that would be a better choice.

I have also considered lithium grease, but have found it is not recommended for sliding applications due to low adhesion.

what would you recommend as a proper grease for this sliding application?

Larry

The 72 project Pantera that I received in February has some scoring on the ZF snout as well. The bearing carrier that slides over the snout does not have as much scoring. I test fitted it dry and it moves smoothly. For final assembly I will grease it and install as is.

I took both of my replacement pieces to CAPS here in Fresno to have them cerakoted.

through my continuing education down the Google rabbit hole, I purchased a tube of Stalube Molly grease, and will use it in place of the Stalube Molly graphite assembly lube.

The lube is designed to break down and melt with hot oil while the grease is not so designed. I don’t know how hot it gets inside a bell housing, but to be on the safe side I’m using the grease.

I also read that lithium greases are not good for sliding friction so that eliminated white lithium grease, which was one of my initial thoughts.

YMMV

Larry

@marlinjack posted:Moly-Disulfide, it's a High-Pressure lubricant. As You said it's assembly Lube. Great for the Tips of New Valves when you're running in New Roller Rockers, and running in new cams.

have you ever used Dow Corning 321 MOLYKOTE ? It is a wet spray that dries thin and hard.

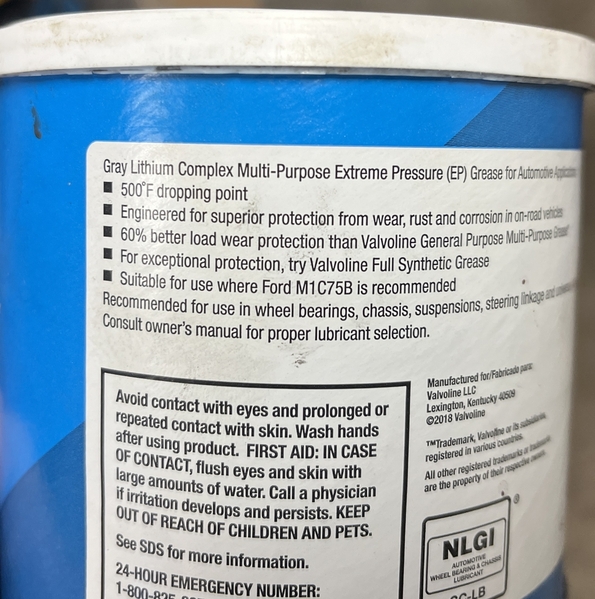

I already have a tub of this. Is it approiate for the sleeve?

Larry, I wondered about ZF heat awhile back, so I installed a temp sensor (0-250F) in the ZF mounting flange to the bellhousing and wired it to a gauge. Then we drove to 'Vegas at 'appropriate' speeds for the mostly-deserted highways.- a 450 mile road trip. The ZF case got to 188F so since the bellhousing is bolted to it, one could assume they both get at least that hot. The engine block on the other side of course may get to 200F+.

One Silver State runner said water accidentally dripped on the ZF after his significantly faster 92 mile run flashed to steam instantly. I checked on my ZF while it was parked under cover at the 'Vegas Hotel, and it took nearly 3 hrs to cool down to ambient temp. That's why GT-40s and Group 4 Panteras had all sorts of tranny oil coolers as-stock. So yes- the Pantera's clutch area gets cooked pretty well, and high temp grease is advised for all the stuff in the bellhousing.

that is very interesting info. high temp wheel bearing grease which is what is supposed to be used on the guide tube operates up to like 600 degrees depending upon what brand and spec you buy so more than good to go in this application. White lithium grease is a no-no. Good only for little gears, etc. And engine build lube absolutely not. The idea here is to provide a light coating to ensure the TO bearing does not stick or in some way rust to the guide tube if it sits for long periods of time.

Moly disulfide fortified grease is designed for sliding applications. It is not recommended for higher speed spinning applications.

So, perfect for the throwout bearing guide, but not so much for something like a pilot bushing, for example.

The Valvoline grease in the photos above is good to 500F degrees according to the back of the tub. Beyond that it goes from its semi solid state to a liquid form. Apparently that is called the dropping point. Our ZF only gets to about 200 degrees. The grease should be unaffected by that.

Sounds like the correct stuff. I watched a couple videos on YouTube of people assembling the TO bearing, etc. onto Ford 5 speeds. They all grease the guide tube and pivot points. Question, some say to grease the front of the TO bearing where it contacts the pressure plate fingers. Is that correct? Also, since the TO bearing is sealed, I assume there is no need to add grease to it? Finally, some also put a light coating of grease on the trans input shaft splines and pilot bearing nose. Comments and thoughts welcomed

thank you Marlin.

@stevebuchanan posted:The Valvoline grease in the photos above is good to 500F degrees according to the back of the tub. Beyond that it goes from its semi solid state to a liquid form. Apparently that is called the dropping point. Our ZF only gets to about 200 degrees. The grease should be unaffected by that.

In my opinion, that is not a correct grease for this application. It is a lithium which is not advised for sliding friction. It has no Molly additives. No graphite additives. Use at your own risk.

this is the grease I have selected.

Larry

I think they are both the same. They are both lithium based with moly added. Satlube says: A special lithium base grease fortified with molybdenum disulfide and polymers. It is used for the installation & repair work on CV joints. Will extend the life of the CV joint & the additives will sustain the shock loads encountered in the CV joints.

I don’t see anything about graphite in the Stalube.

On the face of the Valvoline can it says it has moly:

I am getting ready to bolt my ZF to the engine. Any more thoughts about the appropriate grease for the ZF snout?

Ask Ron McCall. I will before I do mine.

I spoke with Ron McCall this morning and he uses Kendall Super Blu wheel bearing grease on the snout and has been doing so for 20 years. He also said any good quality wheel bearing grease will work. He added that the aftermarket throwout bearing carriers tend to gall. The factory units have a 3/8" shallow groove that gets packed with grease. The aftermarket units don't have this and start scoring when once the grease is gone. The relatively large factory groove acts as a reservoir and provides lubrication much longer.

I also asked Wilkinson which grease he uses on the snout and the answer was synthetic wheel bearing grease. He said not to use WHITE lithium grease.

My carrier has four small grooves: