Oil pressure problem on a 351 Cleveland engine. Oil pressure was running 25 lbs at idle to 70 lbs running. Now it's running 10 lbs at idle to 50 pounds running. Oil level is okay. I replaced the oil pressure sending unit and now the reading is 120 lbs (pegged)???. I replaced the sending unit with a manual gauge on the engine block and verified 10 lbs at idle, 50 lbs at running. I suspect the oil pump failure but, before replacing the pump I'm asking if there is anything else I should check.

Replies sorted oldest to newest

My hunch is that your engine and oil pump are okay.

The oil pressure varies significantly with engine temperature. Mine is pretty much 70 PSI at idle when cold and drops to 35 or so once heated up. I am running 15-40 weight with Liqui Moly Hydraulic Lifter additive.

What oil are you running?

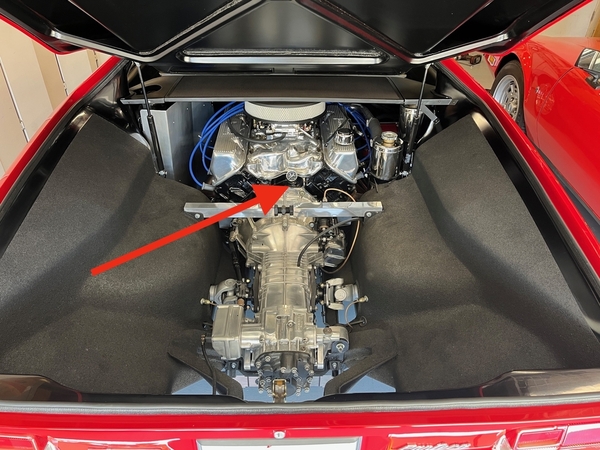

Where is your manual gauge? Below you can see where I get my readings. The sending unit for the oil pressure gauge is relocated near the oil filter.

Attachments

From the Facebook Clevelands Forever group site: "With the engine warmed up and cruising at a steady speed, take your foot off of the gas for a couple of seconds, then back on it a few times. Watch you oil pressure gauge when you do that, and if you are getting a fluctuation in pressure each time you do it, the bearings are probably worn. If it doesn't fluctuate, I'd suspect the oil pump."

Also, the weight of the oil will make it vary as well. I run Valvoline 20W50 VR1. Pressures are like what Steve reported above. 70 all day running regardless of motor temp. Idle at least 35+.

You can join the group and search away as they are a very knowledgable group.

near bell housing.

On Fri, Sep 13, 2024, 12:40 PM The De Tomaso Forums <alerts@crowdstack.com>

wrote:

It isn't just the viscosity of the oil that effects the oil pressure, it is the type.

It is not unusual at all to loose oil pressure as you put mileage on the oil.

This is VERY common with multiple viscosity oils since they are a blend of oil viscosity to begin with and have various additives which are affected by use, i.e., mileage, i.e., the ADDITIVES wear out. Some sooner then later.

10psi at idle hot to me is just indicating a stock oil pump.

There is an "old racer's adage" that says an engine needs 10psi of oil pressure for every 1,000 rpm.

The type of bearings installed internally in the engine also affect the pressure to some degree.

For instance some engine builders recommend 360° grooved main bearings while others will only groove one half of the bearing. That basically is because of the oil pressure variations like this.

I do remember MANY years ago engine builders recommending straight 30 weight oil if using 360° fully grooved main bearings.

Things have changed with improved "engineered" oils now.

Most engine builders that I know of now will recommend 360° grooved main bearings for a Cleveland.

I use them with a high volume oil pump. Some people don't like those because they put more strain on the distributors roll pins that retain the oil pump drive connection at the camshaft drive gear and the Clevelands in particular have shown a noticeable amount of roll pin failures with high volume oil pumps.

I will bet that if you change your oil to a known high performance oil and immediately look at the pressure, it will show higher? If that is so, then it's the oil itself.

You might want to consider looking at your main and rod bearings. The amount of oil pressure that you have lost seems to point to bearing wear rather than a problem with your oil pum.

gradually drop over time?

On Sun, Sep 15, 2024, 8:04 AM The De Tomaso Forums <alerts@crowdstack.com>

wrote:

If it was the rod bearings, you would probably hear a tapping noise as if there was a bolt floating around loosely inside the engine but the noise would be because one or more of the connecting rods was knocking against another due to play in the bearing.

If it was a main bearing it would be a constant oil pressure drop and would have dropped from a normal of maybe 60 psi cruising down to 10. Not just 10-15 at idle.

You can also loose pressure through the camshaft or hydraulic lifters.

There really is no way to tell for sure without dropping the oil pan and opening and examining each and every bearing.

IF they all looked ok at that point then you can measure the clearances using "plasti gauge".

PROBABLY if you have a bad bearing, probably, when you take off the bearing retaining cap, you will immediately see the condition of the bearing and of the race on the crankshaft.

I have seen bearings changed in the car but it isn't easy to do at all and it would be questionable as to how long they were going to last.

It could essentially "self destruct" almost immediately or could be ok for sometime.

Usually it is just the rod bearings that survive being done in the car. I don't know how you would do the complete main bearing without dropping out the crankshaft.

For that it would be better to pull the engine and work like a civilized human?

How many miles are on the engine and do you know it's entire history?

On Sun, Sep 15, 2024, 9:45 AM The De Tomaso Forums <alerts@crowdstack.com>

wrote:

Drop the oil { save some in a clean container } and send it out for a oil analysis.

John, if the pressure reading dropped within a week or so, I'd look closely at the electric sender. Decades ago I had a friend that worked at an auto parts shop. I borrowed a dozen stock NEW senders and tried them one at a time on my engine. I got ten different gauge readings that varied by +/- 20 lbs. I picked the one that was closest to a mechanical gauge teed into the block and returned the rest. I now use the mechanical block gauge if I want to know the true oil pressure; the electric dash gauge only tells me I have (some) oil flowing. Incidentally, the electric water temp gauge reading is also unreliable.

You'll get a higher pressure reading if you add a sender at the front of the block near the fuel pump. That oil comes right out of the oil pump, compared to one in the (stock) rear position, which reads pressure after the filter, all the engine bearings, 16 lifters and any random leaks. Be careful comparing pressure reading with engines rigged differently. A bent or thrown pushrod or lifter out of its bore will notably drop oil pressure. I've found these even on low-rpm diesel engines.

I'd also look at the single wire that feeds the gauge, and the gauge's panel's ground. Odd things happen with the console gauges when the ground wire connections get slightly loose. Rarely is the stock pump to blame. The standard 351-C pump is larger than the ones used in the 427 Ford GT-40s at LeMans. Another rare happening is, the thin-wall oil pump feed line in the pan cracks where it screws into the pump body, so the pump delivers oil and air. Some shops spot-braze the line to the pump or add a brace. Good luck-

50 lbs is plenty, although the gauge is probably lying to you. Drain the oil and sweep it w a magnet before you send it out.... I have a trick motor for sale...lol...

Update on the oil pressure. Talking to a sprint car racer, he suggested adding Marvel Mystery Oil and running the engine. Then change the oil and filter. It worked! The pressure is back to 25 - 70 lbs. His thinking the oil pump bypass was stuck. He adds the Marvel Oil prior to every oil change. Who knew snake oil would work. He convinced me.

@John Czarnecki posted:Update on the oil pressure. Talking to a sprint car racer, he suggested adding Marvel Mystery Oil and running the engine. Then change the oil and filter. It worked! The pressure is back to 25 - 70 lbs. His thinking the oil pump bypass was stuck. He adds the Marvel Oil prior to every oil change. Who knew snake oil would work. He convinced me.

Wow! I've heard that "it's better to be lucky then good!" ![]()

Attachments

The snake oils can work very well with fuel injection on older cars. Lucas fuel injection cleaner in my daughter’s 2011 Subaru made a huge difference. I also used Seafoam on my motorhome’s generator carburetor and it helped a lot. In that case, the motorhome was new, but the carb had been dried out before i got the motorhome. Seafoam also helped my son’s old Saturn with improved MPG. After reading this thread, I will use marvel mystery oil in my euro Pantera before its next oil change.

@John Czarnecki,

did you remove engine oil and dd Marvel to the oil? I'm assuming you did but wanted to double check before I do the same.

Thanks,

John

#3590

@jwelch68 posted:@John Czarnecki,

did you remove engine oil and dd Marvel to the oil? I'm assuming you did but wanted to double check before I do the same.

Thanks,

John

#3590

I usually added a quart of MM oil to the oil that’s in the engine (not new oil) and let it idle for a bit (to temp) .. watching oil pressure… the I drove one time around the block.. nicely…

Turn off and let it sit over night… next day let it idle to temp again and then drain the oil , new filter..

new oil… NO MM oil now!

thats just me..

overfilling the engine oil (if you are at max) by a quart is irrelevant in this case…

@John Czarnecki posted:Oil pressure problem on a 351 Cleveland engine. Oil pressure was running 25 lbs at idle to 70 lbs running. Now it's running 10 lbs at idle to 50 pounds running. Oil level is okay. I replaced the oil pressure sending unit and now the reading is 120 lbs (pegged)???. I replaced the sending unit with a manual gauge on the engine block and verified 10 lbs at idle, 50 lbs at running. I suspect the oil pump failure but, before replacing the pump I'm asking if there is anything else I should check.

I would do an oil change and see if any metal comes out of the pan, maybe drop the pan, if there is silver material in the oil, then you know you have some bearing problems. If its minimal silver material, change the oil and run it, see where your pressure is.

I've put a manual guage on the back of the block on a T fitting so it eliminates the electronic gremlins as a fail safe.

Attachments

...I have heard...Teflon TAPE Messes with a Good GROUNDING. There, and to the Block!

MJ

@marlinjack posted:...I have heard...Teflon TAPE Messes with a Good GROUNDING. There, and to the Block!

MJ

I heard the same thing… I did check quickly with the Ohm meter And it showed no resistance…(I did this when I had the problem with the brand new faulty oil pressure Senders and nothing was working.)

On the final installation I used thread sealant.