I have always had concern regarding lifting my Pantera with a floor jack on the sheet metal boxed sections of the front quarter panel. I have never seen the thickness of the metal in this area, so I am concerned about these sections collapsing, as well as putting undue twist on the chassis when lifting one corner at a time.

So I came up with this lifting fixture / load spreader.

By taking a piece of 1 ½” x 3” rectangular tube and cutting two slots (¾” deep), I created this lift bar for the front of my car. See Figure 1 for bar and slot dimensions. You can use a chop saw, a cold metal saw, or a mill for this task.

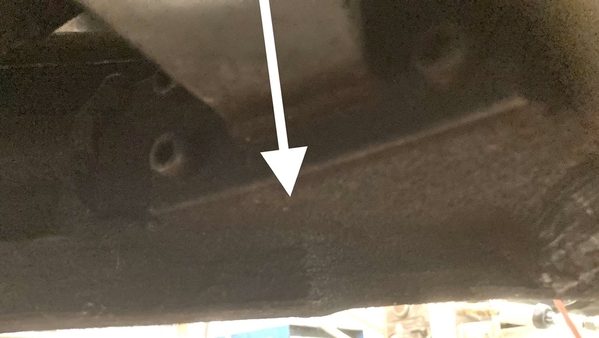

The slots create a positive locating feature for the lift bar on the pinch welds below the car’s frame. The load is spread across both sides of the frame across the bar (see Figure 2). The two triangular gussets across the front of the car’s frame also engage the bar.

The lift bar allows me to jack the front of the car in a level configuration with a single floor jack (Figure 3). I generally place two equal height jack stands in the inner sway bar mount pockets when the front of the car is raised.

(UPDATE): Not sure why the pictures aren't showing automatically, but if you click on them (below) they show up, at least for me.

Rocky

Figure 1. Lift Bar General Configuration & Dimensions

Figure 2. Lift Bar Showing Frame Engagement / Frame Gusset

Figure 3. Lift Bar in Action