is the taller tank supposed to be higher for the swirl tank mod?

Replies sorted oldest to newest

TSB 96 recomended that checking coolant level no longer be performed by removing pressure cap from swirl tank. Damages cap seal.

Instead check for half full in the expansion tank (overflow). to ease access, cut a hole in right engine cover . thus raising the tank would aid in checking level.

For application, IF the taller tank remains as the expansion overflow tank, its relative height with respect to swril doesent matter.

HOWEVER, if coolant system is converted to continous venting, making taller tank the pressure tank, then the elevation becomes importaint as to establish the air volume needed to allow for expansion

Here is a picture of mine. Still need to clean up the cosmetics.

I followed the original instructions for the mod. I keep the coolant level at the 1/8" hose level which leaves enough space for air to purge in the larger tank. I'm using a 13lb radiator cap.

John

Attachments

the taller tank has the vent from the radiator going to it.

you think the top of the cap should be above or around the height of the engine gaurd?

if tank has vent from radiator, is the bottom of the tank connected back to block (at heater hose return)?

do you also have vent from swirl going to tall tank?

as for cap being above engine cover. . . in leu of cutting the hole in original engine cover, the shop purchased one with hole cut. unfourtonetly the hole is in the wrong place so my cap is just below the engine cover.

I don't have log book where I recorded, but I seem to recall filling tank FULL, going from 40F to 190F the expansion peed about 24 ounces. for my tall tank that established an air volume down about 7 to 8" when cold again. this is slightly more than tall tank is above swril, so that means there will be some air in swirl.

while 5177 is back in shop, I have request engine cover hole be enlarged/ovaled and tank raised to have cap at engine cover elevation

Attachments

I think the taller tank would be perfect at the engine guard height.

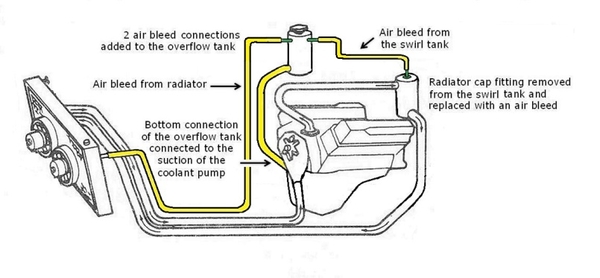

Here is the diagram for mine. I forgot the gentlemen's name, but he wrote up a great explanation for the header tank system and also posted on the GT40 sites. I'm sure you can do a search on this site and read the details.

I'm using a FlowKooler water pump, so it has an extra port to connect to the bottom of the taller tank.

Attachments

there is an "always on top" post about coolant on this site, the G Pence write up is it.

https://pantera.infopop.cc/top...-cooling-system-info

this set coolant arangement was also recomended by a guy name Carrol Smith, (racer/engineer/author)

I also found technical papers from 1940's for similiar arrangements saying the swirl remove entrained gases from coolant