I recently replaced the clutch and pressure plate (from PI Motorsports) and have done my best to adjust everything according to the various posts and readjusted over and over. It just seems like the clutch doesn't disengage far enough, even with the pedal to the floor. Maybe I need a long throw slave cylinder? Iam running "Redline Full Synthetic Lightweight / Shockproof" gear oil but still need to shift somewhat slowly or I get some slight gear interference (just slight, nothing major). It's drivable, but I worry about wear on the syncros over time. Maybe I am just not accustomed to the Pantera ZF gated shifting idiosyncrasies. Does anyone think the issue could be related to the gear oil I used? Any other ideas?

Replies sorted oldest to newest

The Redline gear oil that’s the closest to matching the factory recommendation is MT-90. That being said, your problem sounds more like insufficient clutch release when changing gears. You can measure the clutch release with a feeler gauge, through the inspection hole in the bellhousing. I don’t recall the appropriate measurement but it’s here in the forums, most likely posted by Bosswrench.

Some of the problem is the mechanical part of the clutch release linkage. ALL of it is unhardened-steel-on-unhardened-steel, never lubricated and each little wear clearance is additive. The L model over-center linkage under the dash is particularly susceptible because there are so many steel on steel pieces. After 50 years of this, the clutch disc simply doesn't get enough motion to fully release.

I use a constant-contact throwout bearing that need NO free play at the release lever, which helps. A long throw slave might help, but go thru your linkage and see if there's anything grossly worn. Take that part off and weld up the worn area & redrill. Or add a bronze bushing (or four)..

NO syntectic oil, as above 80/90 or just 90 Limited slip mineral..all it is easy ..just change ever "year" that is more improatant as the 5 synchs and the slimited slip clutch disk do corrode..

Mat

Thanks for all the great suggestions. I will blead the system again, check for wear on the metal-to-metal parts, double check all the adjustments, replace the synthetic oil with a non-synthetic 80W-90 for limited slip. If that doesn't cure the problem, I will try a long throw slave cylinder. Does anyone know where I can buy a long throw slave cylinder for a Pantera?

There are two types of lube: one is straight 80W90 either synthetic or not- synthetic. The second is the same but with a portion of limited-slip additive, sometimes called "Positraction Additive". This material allows a bit of slip in your limited-slip clutches and prevents jerking from stick/slip/stick in tight turns. Its especially noticeable in rain/snow or on other low-traction surfaces.

If your car has badly worn limited slip clutches (3 per side), your won't notice the jerking. So I prefer lube with the additive; it can't hurt and may help low speed handling. Or, you can add anti-slip yourself to plain lube. GM EOS or other; not expensive & doesn't seem to wear out. Note that the Pantera is 50+ yrs old and some mistreated cars still have the original lube. ZF says to change it regularly. As for a long travel slave, the vendors are your best bet. Some are stainless steel.

Dan, before you do anything else, just change the oil in your ZF. Redline admits, most of their GL-5 gear oils are too slippery to use in a manual transmission. You may be experiencing this with the gear oil you're using. According to Redline, MT-90 (GL-4) is the exception. Its intended use is in manual transmissions and transaxles where a GL-4 gear oil was originally specified. When I switched from petroleum based to MT-90 synthetic gear oil, I immediately noticed shifting was easier. Lloyd Butfoy (RBT) says the only problem he finds with synthetic gear oil is, you're more likely to develop leaks.

If you decide to use petroleum based gear oil, keep in mind, the factory recommended spec. is 80W-90 GL-4. Some GL-5 oils may work fine but this is what ZF (and now RBT) recommends. Regardless of what lube you use, RBT recommends you change it annually, regardless of mileage.

Attachments

@bosswrench posted:Some of the problem is the mechanical part of the clutch release linkage. ALL of it is unhardened-steel-on-unhardened-steel, never lubricated and each little wear clearance is additive. The L model over-center linkage under the dash is particularly susceptible because there are so many steel on steel pieces. After 50 years of this, the clutch disc simply doesn't get enough motion to fully release.

I use a constant-contact throwout bearing that need NO free play at the release lever, which helps. A long throw slave might help, but go thru your linkage and see if there's anything grossly worn. Take that part off and weld up the worn area & redrill. Or add a bronze bushing (or four)..

Here is the state of the speader on mine when I disassembled it

And here it is after fitting the needles sleeves

Attachments

You can search the forum on the choice of ZF oil as it has been discussed numerous times but I will state what Roy Butfoy (Lloyd's father) told me when he rebuilt mine in 1990 - Use Castrol 80W90 GL5 gear oil (NON synthetic) and change it annually. Why do something different than what the master directed. His advice has served me well for 32 years.

After reading RBT's recommendation along with input from others on this thread, it seems like there are not many offerings that are suited for out transaxles. I have zeroed in on one that looks like it is a correct match. It is a mineral oil and is API GL4. It is called:

VP Classic® Hi Performance SAE 80W-90 API GL4 Gear Oil

Here is a link to it:

https://vpracingfuels.com/prod...e-80w-90/?c=261&

Does this look like a good fit?

I've not heard anything bad about Redline in ZFs. But keep in mind that our ZFs do not normally have any yellow metal inside them- usually referring to the sacrificial bronze or brass synchro rings in many American transmissions. ZF uses all-steel synchro rings that last much longer than brass. There were a few brass ZF synchro rings produced or adapted by unknown shops some years ago, but I haven't heard about them in awhile.

Steve,

I don't see any mention of a limited slip additive for the VP Racing oil.

John

Jack,

My experience with Redline was that shifting was slightly easier and my fairly new side and input shaft seals started leaking. I spoke with Lloyd Butfoy and he suggested draining the Redline and refilling with whatever gear oil I had been using before I tried the Redline. Problem (leaks) solved.

John

John, good catch. I suppose the limited slip additive could be added to the VP oil. Which oil are you currently using?

If you want a mineral based 80W-90 GL-4 gear oil, there are a few available, including Driven GO, PennGrade 1 (formerly Brad Penn), Castrol and the VP Classic Steve mentioned. My ZF's have always worked fine without any limited slip additive. Perhaps you should only add it if you find you need it.

Hi Jan,

I have used it before and it seems fine, but have switched to VP Racing Classic GL4.

Lloyd writes the following in his RBT website:

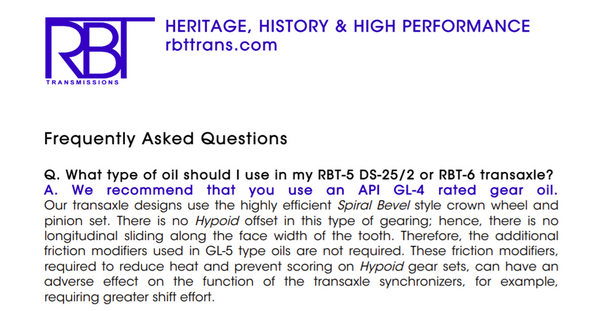

Q. What type of oil should I use in my RBT-5 DS-25/2 or RBT-6 transaxle?

A. We recommend that you use an API GL-4 rated gear oil.

Our transaxle designs use the highly efficient Spiral Bevel style crown wheel and pinion set. There is no Hypoid offset in this type of gearing; hence, there is no longitudinal sliding along the face width of the tooth. Therefore, the additional friction modifiers used in GL-5 type oils are not required. These friction modifiers, required to reduce heat and prevent scoring on Hypoid gear sets, can have an adverse effect on the function of the transaxle synchronizers, for example, requiring greater shift effort.

Attachments

Thanks, I may give that VP Classics a try in my other Panteras now that I see the Valvoline is for non-synchro trans. Here is some addl info on the VP Classic in the link below. I would use Castrol GL4 80-90 but here in the US it's easier to buy crack than that.

Caution on the oils that indicate they are for non-syncro transmissions assumes that the synchronizer rings are made of brass. Some of those GL5 additives are not compatible with brass.

as previously outlined above, that is not the case for our ZF and the caution against a GL5 oil is not applicable to our transaxles.

Larry

Lloyd is recommending GL4 because it makes shifting easier. There is no brass in a ZF or RBT transaxle. VP suggests that their gear oil does not harm brass synchros. We should not buy GL4 based on it being kind to brass and instead that it makes shifting easier as Lloyd describes. He says the hypoid additive works against our synchros. I cannot be judge on this and will yield to the expert.