Like you all have experienced, you are working on a specific project and the door panel is off, or the seat is out… you know there is something else that is staring you in the face.. 😳 it’s asking for your attention! So suck it up and do it… I suck a lot up… today I posted finishing the fresh air intake for the cabin and looking at the post it seems like … well, he puts a hose on today.. but as a working day goes, you come across a lot of things that 😳🤓🥹🥸🫣 look at you and ask to be fixed… some minor, some ugly and some x-file stuff that some alien built….

This thread is mainly for me to keep track of things I did and for your entertainment or for you to check next time you’re in that area…

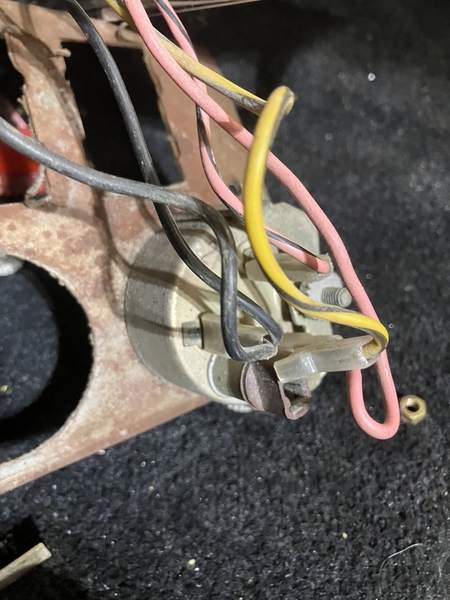

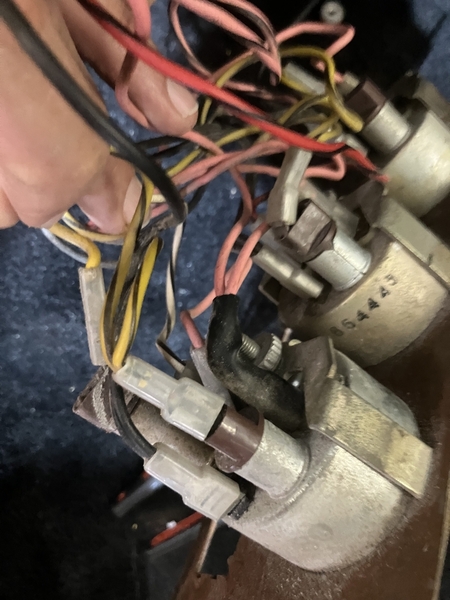

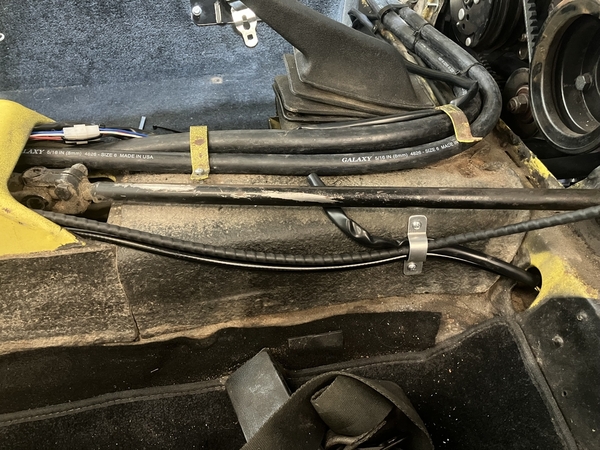

Door panels off.. we are redoing the 50 year old interior, we’ll hand it to the upholstery guy with some instructions! oh my… look at the bottom of the doors.. there is a lot of things, metal(bolts,washers, a small pin?), leaves, debris, blocking the drain holes… clean that out.. bolts… hmm I’m sure they had a home and so did the washers - you see where this goes… we ended up taking the window regulators out left and right, opening both gear drives and I found to my delight that it had already bronze gears in it.. solid with hard baked Brown grease … you know what to do.. cleaning regulations, lubricanting everything and put it back together, finding the washers were spacers to make it run smoothly…

what’s that.. pin… broken spring from the drivers door handle… take the handle out… and the passenger as well..

never tried the key… hmm doesn’t work, not left not right BUT fits the rear lid👍

back to driver door handle… plastic bucket is cracked too.. finding a used spring…. to get it : the pinhead, carefully drilling the head off and carefully driving it down… Getting stuck rust , cutting a bit off driving it backwards, cut again, tapp tap it’s out.. I got a spring.. new bucket came with pin and C-clips..

same again

cleaning the used spring.. ent-rust it , paint black.. well, still no key… I know a guy… he did the ignition lock on my Jensen Interceptor… old guy… on my way home I see him in his little locksmith shed next to .. Lowe’s..

tell him what I got… he’s looking around and after 5 minutes he shows up with 6 keys… says Fiat on them… smile…

the old man says… you know, I had a DeTomaso 40 years ago… got stolen…

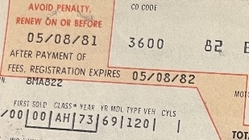

yahh a silver Mangusta… 1982 it got stolen… still got the keys and the title and a ticket…

VIN 8MA822

I have to laugh right now where this is going…

anyway, he made me the key...driverside

More to Come