My buddy has a fab shop and he would consider building us parts if there was a response or need.

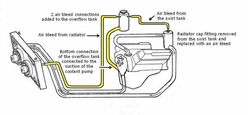

He built me these coolant tanks with the vent mod and they came in around 580 bucks and the next set would be better as revisions and requests are applied.

He is a journeyman power plant welder and he built a beautiful fuel tank for my boat. He is willing to build a few fuel tanks if there is a need.

I have a spare fuel tank here that I will take down to him.