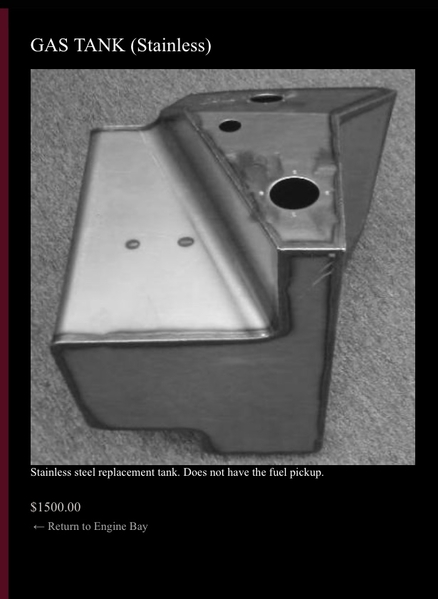

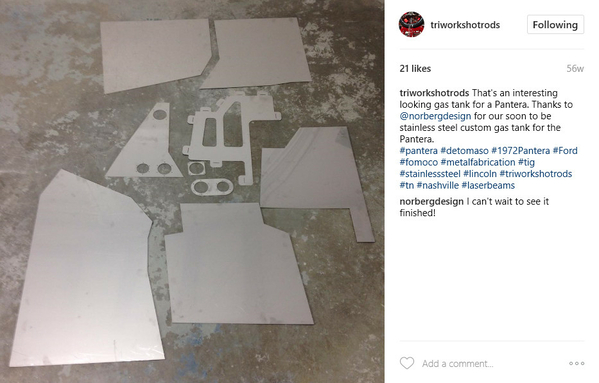

If the choice was mine, I would spec aftermarket gas tanks as follows-

1- no heavier than stock- which are pretty light for steel

2- corrosion resistant- thin ss or aluminum

3- sender as-stock, with a separate bung for EFI/carb return line

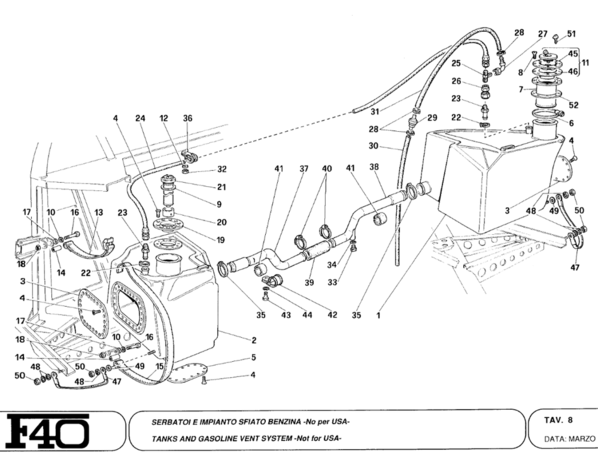

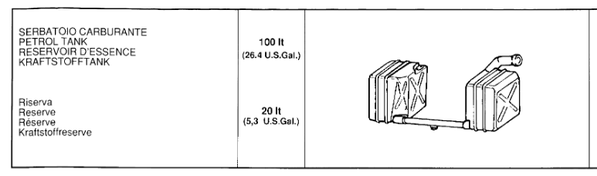

And if it were just for me, the best Pantera fuel system I ever saw was on a Euro Gr-3 street racer as sold in Europe '71-about '79. It had two 10 or 11 gallon tanks, one on each side with a 2-1/2" OD connecting line & vent running in front of the crank pulley above the radiator hoses. There's far too much weight on the left side of our U.S cars so this better balances the machine. Stock, 22 gallons of fuel weighs 150 lbs! VERY difficult to cross-balance such a car with driver AND full tank! Two small tanks can be simpler to build than one big one, as well.

The headers on the left side are constrained by the tall stock fuel tank, requiring a heat shield. Dual tanks do not need shields. The Italian fuel sensor is fine as is and the stock size access hole allows adding a stock Ford TBI fuel pump to the end of the sender ass'y. Inside mounted electric pumps run cooler and much quieter. All modern EFI cars since the 80's have inside the tank pumps. TBI runs at 12 psi so it can be regulated down to 6-7 psi for carbs, unlike EFI that runs at 48-55 psi & cannot be regulated down without overheating the pump. My two cents-