I tend to agree with this.

To add credibility to it, Ford actually had admitted culpability back then in only offering replacement pistons at .002" oversized.

Today you can order any size replacement pistons and matching rings for $500 and $125.

You need to take the engine to a Ford specialist and have the thing honed, not bored and let the shop spec the size of the piston and rings.

In theory, they can all be different sizes.

So I suppose this is going to eliminate Ebay as the parts source and you will actually need to talk to a real live person?

FYI, JE Pistons (SRP) has a catalog offering for forged flat tops in .010, .020, and .030 inch oversize at a reasonable price.

Those are standard sizes. There is no reason to stay with standard sizes now.

With a Cleveland as well as a 427, a 428 or ANY "vintage" block it is to your advantage to minimize the overbore.

For one thing that gives you more possibility of a rebuild sometime down the road without having to worry about replacing or sleving the block.

With a Cleveland as well as a 427, a 428 or ANY "vintage" block it is to your advantage to minimize the overbore.

For one thing that gives you more possibility of a rebuild sometime down the road without having to worry about replacing or sleving the block.

I found on the web the height of the block (9.206" is not it?), but what is the length of the cylinders, I didn't find ?

Okay for 9.215", I found 9.206" in George Reid's book "FORD 351 Cleveland Engine, How to build for max performance"....

For the moment I'm inquiring, I will certainly increase the engine displacement but when I look at the prices I see that the difference is low between rebuild my engine with a stroker kit myself or buy a new one.

If I rebuild the engine myself, it's the same for the heads, if I keep the original ones (4V Open chamber), the price of valves + dual springs + retainers + rockerarms + machine work + ... is only a very little sheaper than new complete aluminium heads.

If I rebuild myself, I look at the different possibilities and wanted to well understand why you recommend not to exceed 3.75"stroke while there are a lot of kits with 3.85 and even 4" stroke.

So, I think, I think .....

For the moment I'm inquiring, I will certainly increase the engine displacement but when I look at the prices I see that the difference is low between rebuild my engine with a stroker kit myself or buy a new one.

If I rebuild the engine myself, it's the same for the heads, if I keep the original ones (4V Open chamber), the price of valves + dual springs + retainers + rockerarms + machine work + ... is only a very little sheaper than new complete aluminium heads.

If I rebuild myself, I look at the different possibilities and wanted to well understand why you recommend not to exceed 3.75"stroke while there are a lot of kits with 3.85 and even 4" stroke.

So, I think, I think .....

quote:

Originally posted by René #4406:

... I will certainly increase the engine displacement ...

Why?

quote:

Originally posted by René #4406:

... wanted to well understand why you recommend not to exceed 3.75"stroke ...

I've already explained. You are welcome to ask me for clarification if there's anything confusing you.

quote:

Originally posted by René #4406:

... while there are a lot of kits with 3.85 and even 4" stroke ...

Do you remember the story of the king with no clothes. All the people commented how well adorned the king was. Nobody wanted to be the only person who saw no clothing. I have confidence in myself, I'm not afraid to speak up when there is bad engineering. Or, to express it another way. I have nothing to gain by lying to you, because I don't sell crankshafts.

quote:Originally posted by George P:

[QUOTE]

Originally posted by René #4406:

... I will certainly increase the engine displacement .

Because I want my Pantera to have an engine at the level of his so sporty and so aggressive look and I would like to have a 400/450 hp STREET engine to have about 3 kg per horse (or 330 hp / ton). But if it's possible to get 400/450cv with good power at low and medium revs, replacing only the pistons for higher compression ratio, the camshaft and the valve train, the intake manifold and the carburetor, why not?quote:Originally posted by George P:

Why?

quote:Originally posted by René #4406:

... wanted to well understand why you recommend not to exceed 3.75"stroke .

Yes, you have already explained and I understood, but I like to redo the calculations myself especially if I don't buy a kit but separatly partsquote:Originally posted by George P:

I've already explained. You are welcome to ask me for clarification if there's anything confusing you.

quote:Originally posted by René #4406:

... while there are a lot of kits with 3.85 and even 4" stroke ...

And that's why your article is very interesting and that I thank you but I like to get deeper into things. (3.85" or 4" crankshafts aren't more expensive than those of 3.75"quote:Originally posted by George P:

Do you remember the story of the king with no clothes. All the people commented how well adorned the king was. Nobody wanted to be the only person who saw no clothing. I have confidence in myself, I'm not afraid to speak up when there is bad engineering. Or, to express it another way. I have nothing to gain by lying to you, because I don't sell crankshafts.

George,

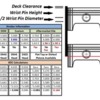

In reference to your Stroker Information chart, can I confirm the deck height as I am having Mahle make me up some custom pistons and I just want to get my calculations correct.

1/2 3.850 stroke + 6" rod length + 1.275" wrist pin or comp height - 9.206" deck height = -0.006" (below deck).

I have seen a couple of places were these measurements said these were zero deck but the math does not add up for me.

In reference to your Stroker Information chart, can I confirm the deck height as I am having Mahle make me up some custom pistons and I just want to get my calculations correct.

1/2 3.850 stroke + 6" rod length + 1.275" wrist pin or comp height - 9.206" deck height = -0.006" (below deck).

I have seen a couple of places were these measurements said these were zero deck but the math does not add up for me.

The true "nominal" deck height of a run of the mill production 351C is 9.215 inch, unless you have a Boss 351 block, then its 9.206 inch. That's where the 9.206 dimension came from. The Boss 351 dimension is repeated in several books and even in Ford's SVO catalogs. But its in error. Just like a 351C with 11:1 compression has always been in error.

A good machine shop can level the decks, and make the two banks equal height, by shaving nominally 0.015 off the decks. That takes them down to 9.200. That's all the milling any Cleveland block I've ever seen needs to true it up. But just as often these days I've seen the decks taken down to 9.190 and even 9.180 a time or two.

I've seen piston manufacturers and crankshaft (stroker kit) manufacturers use 9.213 (Ross), 9.200, and 9.190 (Scat) for the 351C deck height. Obviously the manufacturers using 9.200 or 9.190 are assuming the decks have been milled.

A good machine shop can level the decks, and make the two banks equal height, by shaving nominally 0.015 off the decks. That takes them down to 9.200. That's all the milling any Cleveland block I've ever seen needs to true it up. But just as often these days I've seen the decks taken down to 9.190 and even 9.180 a time or two.

I've seen piston manufacturers and crankshaft (stroker kit) manufacturers use 9.213 (Ross), 9.200, and 9.190 (Scat) for the 351C deck height. Obviously the manufacturers using 9.200 or 9.190 are assuming the decks have been milled.

Great thank you George.

That makes sense. You really need to measure to ensure everything is as expected. I am now running a 9.194" deck height after a 0.006" cleanup from the previous build.

That makes sense. You really need to measure to ensure everything is as expected. I am now running a 9.194" deck height after a 0.006" cleanup from the previous build.

Here are perfectly clear explanations.

Thank you George.

Thank you George.

??????

The volume of the combustion chamber does'nt appear on the list.

The volume of the combustion chamber does'nt appear on the list.

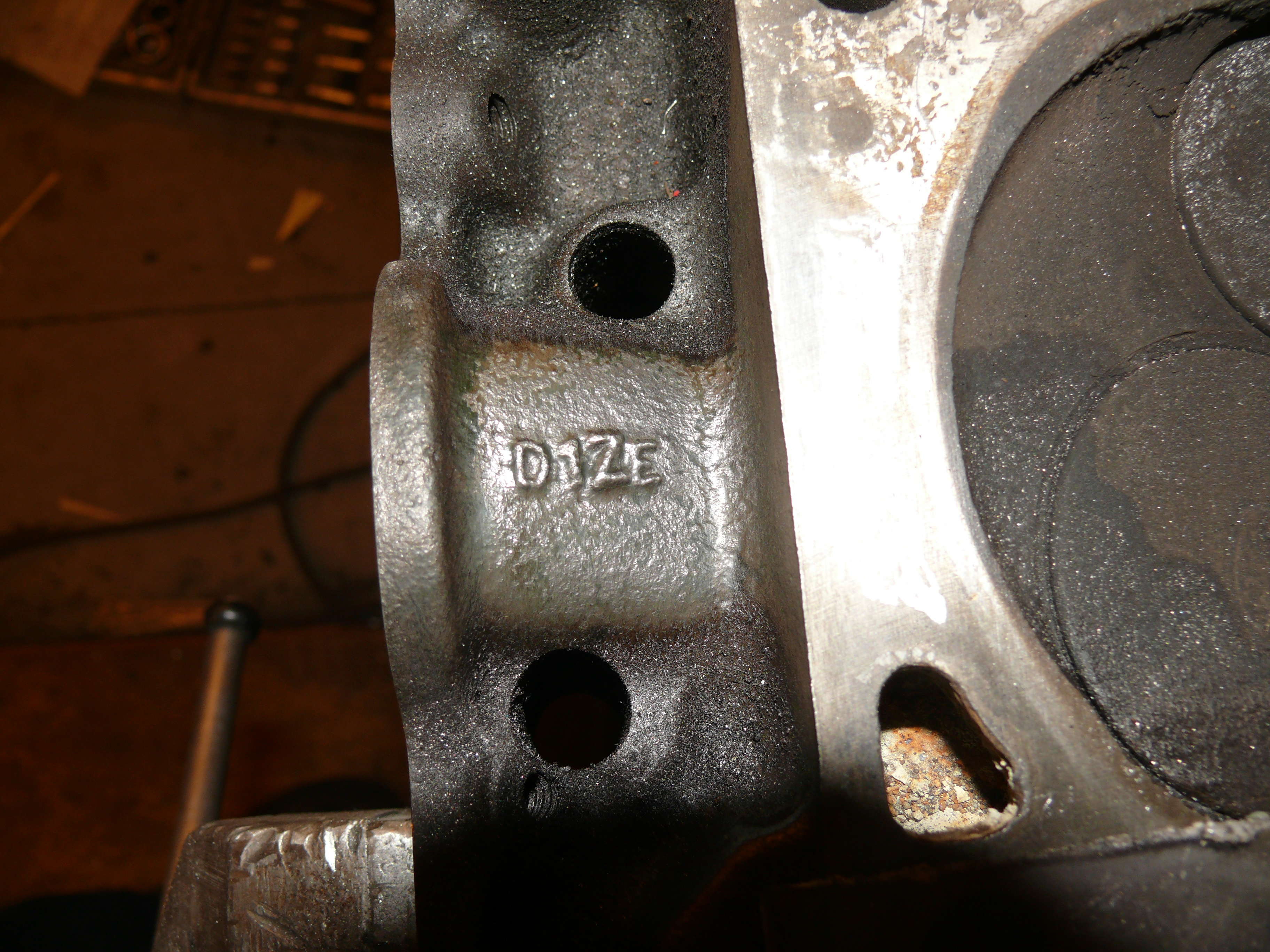

Yes I've heard of this. I've also heard of D3ZE heads with the larger 4V sized valves. There was obviously a transition period during construction that occurred in this order:

D1ZE heads were cast with larger chambers

The casting number changed from D1ZE to D3ZE

The valve sizes were reduced from 2.19/1.71 to 2.04/1.65

D1ZE heads were cast with larger chambers

The casting number changed from D1ZE to D3ZE

The valve sizes were reduced from 2.19/1.71 to 2.04/1.65

quote:Originally posted by René #4406:

??????

The volume of the combustion chamber does'nt appear on the list.

OC or CC

Open (76-78cc) Chambers or Closed (61-66cc) Chambers

Yes, transition period, mine still have big valves 2.19 and 1.71" BUT already the big chamber of 78.5CC.

I'll have to mill them to get a dynamic ration of 7.8: 1

My question was about the volume of OC, 75.4 or 78.4 CC but thanks anyway for the link.

I'll have to mill them to get a dynamic ration of 7.8: 1

quote:Originally posted by 4V & Proud:

OC or CC

Open (76-78cc) Chambers or Closed (61-66cc) Chambers

My question was about the volume of OC, 75.4 or 78.4 CC but thanks anyway for the link.

George, you recommend titanium retainers, at Manley the difference in weight is 6 g for only $ 30, the price is so not a criterion but for a street engine that is not intended to be disassembled often, is there no more risk of breakage with titanium than with steel?

Not so much breakage (on the street) but wear. It's recommended to use a small grinder or sharp file to polish every spring & damper edge in contact if you use aluminum or titanium spring washers. The usual sharp edges even on used springs or dampers will saw thru softer alloys in short order, if you rev the engine to the point where light-alloy parts make a difference.

Ti or aluminum washers also can be had in various assembled heights, changing the way the rockers contact the valve stems. So you need to know what you need. And of course, the stock multi-groove intake & exhaust valves should be consigned to a trash bin before they break and destroy the engine or at least the head(s). Good luck.

Ti or aluminum washers also can be had in various assembled heights, changing the way the rockers contact the valve stems. So you need to know what you need. And of course, the stock multi-groove intake & exhaust valves should be consigned to a trash bin before they break and destroy the engine or at least the head(s). Good luck.

Valve retainers are not high wear items, as long as (as Jack warned) the springs wearing against them have no sharp edges.

My preference with valve train parts is to lighten them as much as can be done for a reasonable amount of money, and then use springs of "moderate" force. This is the best strategy for enabling hydraulic valve train to rev to 7200 rpm, and for reducing valve train wear in street engines that are expected to operate many miles without maintenance. And of course stainless valves and titanium retainers are the most "cost effective" manner for reducing valve train weight.

Side note: stainless steel is not that much more durable than titanium, yet the valves are much higher wear items than the spring retainers. Stainless valves give me more concern about wear than titanium retainers.

The need for light weight valve train becomes more important as valve lift (lift rate) increases and as the engine's rev limit increases. You can substitute lighter parts with stronger springs, but only to a small degree IF the engine is equipped with hydraulic tappets because very stiff springs can lead to premature tappet collapse.

On the other hand, if the engine shall be rev-limited at 62000 rpm, or if valve lift is moderate, chromoly retainers should be fine.

My preference with valve train parts is to lighten them as much as can be done for a reasonable amount of money, and then use springs of "moderate" force. This is the best strategy for enabling hydraulic valve train to rev to 7200 rpm, and for reducing valve train wear in street engines that are expected to operate many miles without maintenance. And of course stainless valves and titanium retainers are the most "cost effective" manner for reducing valve train weight.

Side note: stainless steel is not that much more durable than titanium, yet the valves are much higher wear items than the spring retainers. Stainless valves give me more concern about wear than titanium retainers.

The need for light weight valve train becomes more important as valve lift (lift rate) increases and as the engine's rev limit increases. You can substitute lighter parts with stronger springs, but only to a small degree IF the engine is equipped with hydraulic tappets because very stiff springs can lead to premature tappet collapse.

On the other hand, if the engine shall be rev-limited at 62000 rpm, or if valve lift is moderate, chromoly retainers should be fine.

I have read and re-read this article for weeks. I am so happy to have found this resource. I never expected to find anything this exhaustive when I set out to search the internet for tips on optimizing my 351 Cleveland 4V rebuild. I only hope I can find a builder for the heads that will adhere to the information in this article. I have found that builders have their own ideas about what should be done and they are not that open to input. Anyway, thank you for sharing your experience and knowledge.

I would like to thank you for this(those) usefuls article(s) that I have used for the rebuild of my engine (351C-4V Q code Open chamber). I have installed the bushing kit from Wydendorf Machine, it's easy to do but it's stressful.

Add Reply

Sign In To Reply