Question for those in the know. How long would it take working at a moderate pace for complete Disassembly and reassembly?

Replies sorted oldest to newest

With or without the necessary and specialized tools?

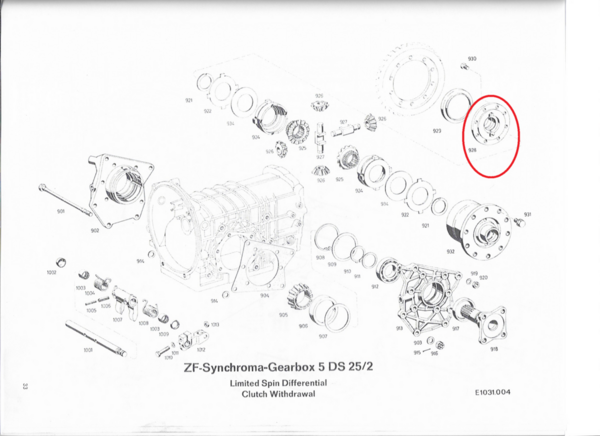

from those in the know I have learned that the transaxle, although more exotic than a Muncie or a Toploader, is not rocket science if you understand transmissions. They say the problem comes in finding the proper tools and then re-assembling everything with the proper clearances

not a project for the timid

Larry

We (Wade - MkIV4280, or something like that) took my ZF apart on two occasions.

First, we replaced the bolts on the ring gear, and safety wired them. That was accomplished in about 2 sessions of 5-6 hours on two consecutive days.

Second, we swapped out my second gear synchro, and swapped out my 5th gear for a taller gear.

The second project took a lot longer.

It took us about 2 or 3 six (6) hour sessions to carefully disassemble the box. My transaxle was disassembled for about 3-4 more weeks waiting for parts (you can read about my progress in my build thread).

Careful reassembly probably took us about two additional 6 hour sessions.

Remember, I’m a bonehead, and I’ve only done this exactly two times. But I will say that with the guidance of a guy who had disassembled VW transaxles, and being very careful, we were completely successful in both the synchro replacement, and the install of the taller 5th gear.

Guys who have all the parts, and lots of experience (Ron McCall, Lloyd, Roy , and Les Gray) may chortle at my pace - but it is what it was…. AND we got it done!

I will also say that Lloyd Butfoy was very helpful with some phone consultation, it seemed to me he had his hands full with his ongoing workload, but was happy to provide advice to someone working their own box…

A ZF is not magic, it’s just precision. It can be done if you can build a couple fixtures, and are (very) careful. BUT - It is complex!

Rocky

If this link works, you can see a discussion on my ZF 2nd gear syncro fix, Plus more links to my overall build thread.

ZF Synchro Repair Discussion | The De Tomaso Forums (infopop.cc)

For information on the fixturing needed on a ZF disassembly, look at page 6 of my 5357 build thread....

Can you remove the ring gear and carrier assembly from the housing without pulling the side bearings off the carrier?

I don’t think you can get the two long bolts out of the bottom of the ZF case (which hold the bottom cover on) without pulling the ZF, or at least raising it so high that those bolts clear the frame rails……

Then, once you have the ZF out, your access is really restricted if you are trying to work on the ring gear and carrier only through the bottom of box

it’s 10x easier to work on things with the carrier out than in.

Rocky

Hi Rocky, Thanks for the reply. I have the trans out of the car. I am installing new 3.56;1 ratio. as i recall. I cannot remove the carrier from the housing without removing at least one side brg. can you confirm.. i need to mention this is a -1 trans.

Mine was a -2, but we had to pull the side covers to get the carrier and ring gear out.

Wasn't too hard, but be careful with the torque on the reinstall of the side cover bolts, you don’t want to strip any out.

Rocky

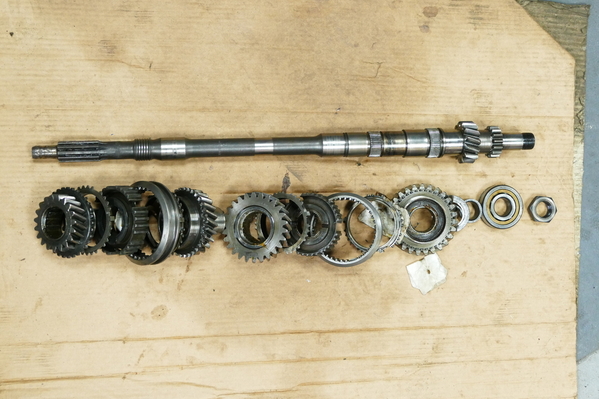

I have just completely disassembled mine, nothing complicated but I made myself the special tools to extract the fixed hubs from the synchros and I have a hydraulic press also homemade.

I took 6 hours taking my time and not counting the manufacture of tools.

I haven't reassembled it yet, I'm waiting for the parts.

Without these special tools it must be much more difficult.

Attachments

i appreciate the feed back however. Maybe you guys are not understanding my question. I have the trans completely disassembled and the new 4th gear set installed. ( the -1 had a very short 3-4 shift. I replaced it with the same ratio as the -2. .846 Gear stacks are reassembled. I need to remove the diff. carrier from the housing and it will not come out. ( yes side covers are removed). The only way i see possible is to pull at least one side diff brg. to allow enough room to slip past the housing. then i can change the ring gear.

Yes, you have to remove a bearing or the 8 screws from the limited slip differential cover and remove the cover with the bearing.

Thanks Rene. being that it is safety wired makes it a bit more difficult when re-wiring. But i guess only the two bolts.

Interesting... This must be the later version. the small end of my carrier is fully welded. it splits apart at the ring gear to access the limited clutch pack.

Tyler5, Yes. on the -1 diff, the assembly will not fit out of the housing with the bearings in place. ( And rene4406, the housing does not come apart like the -2 version)

I would suggest, simply break the outside cage of the bearings and replace them once the diff is removed. They are fairly inexpensive and should be easy to locate replacements. And those bearings tend to collect quite a bit of debris anyway. I replace them on every build.

Ron McCall

Thanks Ron, i ended up removing one side brg. and found the carrier would still not come out. So I separated the carrier at the ring (crown) gear. removed it in the two pieces. Re-assembled reverse procedure. But with new 3.56:1 ratio, Just a real pain to re-safety wire ring gear bolts. -1 definitely different. the other real tricky part with the -1 is the shift collar spring and ball detents. 1 ball.. easy. 2 balls tricky.. 3 balls.. wear safety glasses as they will all tend to fly across the room. lol. rubber bands help but not consistent.

thanks again to all!!

m).

m).