the weather was suppose to be rainy, but just cloudy and misty. I thought that would be good lighting to take some pics. (then took an hour drive!)

the dash was original covering, but from another since mine got "lost". the rocker wiper & washer switches were move to gauge console. the emergancy flasher switch moved to the dash illumination rehost position. the light between speedo & tach is now a two color LED that provides warning of "low oil press" as blue and "high coolant temp" as red. the small display on right for the Holley Sniper fuel injetion. the left is Garmin 55. steering wheel is Nardi that was when I got car. the heat / ac controls, the lower lever is conected to double swith, center off, left turns on AC compressor and right opens heater solinoid valve

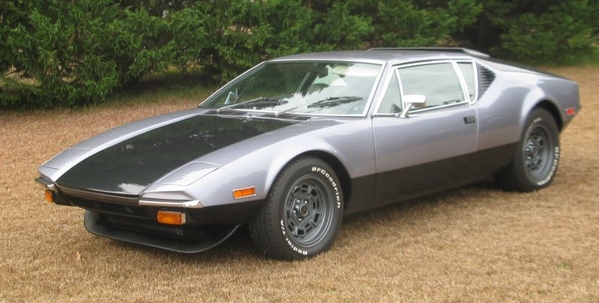

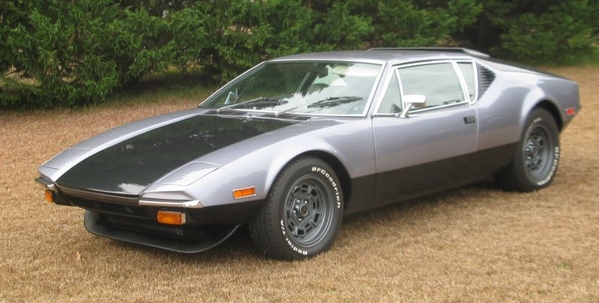

side / front / rear views

corner views

some of the details i wanted

replace the "L" bumpers with bright bumperettes and the alignment of those with the hood gap,

another the fitment and angle of the front spoiler.

(i am thinking . . . putting a wood "skid" under the recovery hooks, 1/2 X 3" oak) ???

AND the exhaust tips !

the tire lettering , the valve stems and center logo all were indexed.

a challange was my desire to have an original air filter housing fit under the engine screen and not tilted. my fiberglass tube had been shorten (for as purchase turbo installation). But it gives a good view of engine.

my center engine screen had a little rust on the end strips so They got a New one from one of the vendors. I don't know which one. Does this look like something that maybe came on an earlier car. that is the solid section is just tack welded to the screen ! looks cheap to me, (but it sure wasn't). the gloss paint has dust stuck to it.

The Plate Opening is 2.100" Wide X 3.860" Long.

The Plate Opening is 2.100" Wide X 3.860" Long.