Here's a dyno sheet of essentially a Boss 351 in a 68 Shelby GT350.

Those are Weber 48ida's with short stacks.

It's an iron head, closed chamber 357. 10:1 cr. Compcams "Weber" cam.

Here's the car.

Attachments

Original Post

Replies sorted oldest to newest

quote:

Originally posted by René #4406:

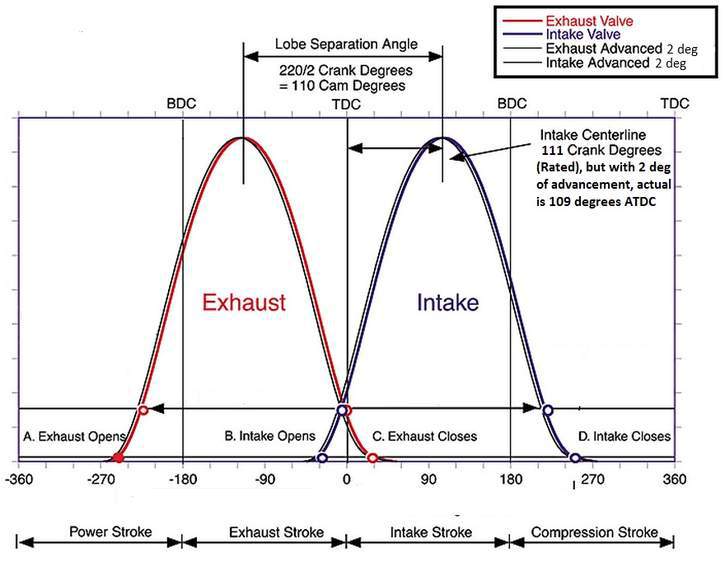

115 ° lobe separation, it seems to me that this is the value George recommends for a street engine?

quote:Originally posted by René #4406:

It would be best if the cam grinders publish the lift curves. I have never understood why they do not do it, I know that they consider it to be their Know How but it is false since it is possible and easy to take these curves.

In addition it would allow to calculate the clearance between the piston and the valves and calculate the depth of relief valves without having to do a lot of tests.

quote:Originally posted by PanteraDoug:

The procedure for determining piston to valve clearances is a standard/known procedure.

You don't calculate it, you measure it with clay.

For safety a "standard" number is used. I think it is .080" on the intake, .100" on the exhaust.

US pistons are all made with those considerations and you don't get close until you are around .650" lift.

So that really puts the "Pro Stock" and NASCAR type engines in danger with .700+ lifts.

quote:

Originally posted by Gazoz:

George could you please explaine the hydraulic roller cam intencity number.or if you already have in the past just direct me to were i should be?

quote:Originally posted by René #4406:

And if I see that there is not enough clearance, what do I do? I deposit the head, and I dig valves relief ..... if there is enough margin with the top ring.

But I agree, the weak spring is more practical than the clay.

quote:Originally posted by PanteraDoug:

I have never seen a graph of a cam lift.

The closest clearance is at maximum lift at the highest point the piston is at, unless you have invented a new form of physics?

I suppose in this era of alternative facts anything is possible? I must live in an alternate reality?

quote:Originally posted by PanteraDoug:

The procedure for determining piston to valve clearances is a standard/known procedure.

You don't calculate it, you measure it with clay.

For safety a "standard" number is used. I think it is .080" on the intake, .100" on the exhaust.

US pistons are all made with those considerations and you don't get close until you are around .650" lift.

So that really puts the "Pro Stock" and NASCAR type engines in danger with .700+ lifts.

quote:Originally posted by René #4406:

I do'nt agree, the minimum clearance may occur a bit before or a little after the top dead center, I checked it on other engines where I was using a camshaft with a lot of overlap and very fast openings and closures.

Anyway, I never asked how to check that, I know how to do it, I just said that having the lift curve facilitates this check.

My subject was above all the supply of lift curves by cam grinders in order to really compare camshafts with each other.