AHAH!!! FINALLY, I ran across an old folder of low res GOose pictures that I have never managed to find let alone re-file......as there are ball joint photos!!! And more!Original style ball joint. Upper plate cracks and turns stud loose on the public! Avoid this style if at all possible....or buy spares....and life insurance policy...up your collision coverage too......!

Newer style cast all in one. Mystery part number??????

Upper A-arm all ready to go back on.

Improved style A-arm with reinforcement over the ball joint cup and all the way down the length of the arm. Material is "U-shaped" and "stitch-ish" welded...not solid beads.

Proper "needle" style fitting for grease guns and UniBal joints!

I know this doesn't help find the ball joints.......keep diggin! Scour the earth for niche Fiat businesses!

Steve

Attachments

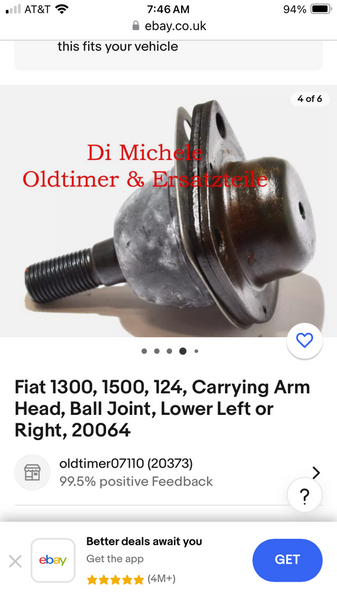

The Fiat style joint for the 1100-2300 listed in Ebay UK item #115683332101 that Lee posted looks perhaps to be the best candidate yet????

I would ping the seller to get the dimension/diameter of that lower casting piece that fits into the Goose a-arm........run to the bank from there.....if need be????

There were some other candidates.....many listed as lower for other cars.....that looked interesting. Again, I was looking only at the "one piece" castings and not the stamped multi layer steel versions.......

Steve

Ran across this picture of my car at a PCNC tech session, preparing for Vegas POCA show I believe. It sez 2006 but I wonder about that.....seems like it should have been earlier......brain fade! But figured you'd enjoy the story....

What started out as a "look see" as to why my front tires were wearing oddly....new tires......and turned into a full on "ball joint" fest...... I had to have my son dig out my 4 new ball joints from my parts stash in my garage about 15 miles up the road, THEN convince my wife that she needed to joint the party and bring them down......that was easy.....the convincing thing....! ![]()

Note the old Koni and original spring. If I didn't replace all 4 front joints that day, I most certainly did the job shortly after!!! ....and got it realigned!

![SteveL[1] SteveL[1]](https://pantera.infopop.cc/fileSendAction/fcType/0/fcOid/1598208419924711/filePointer/26812249033097219/fodoid/26812249033097214/imageType/SMALL/inlineImage/true/SteveL%255B1%255D.jpg) Seems like I worked on everything on the car....at a low altitude at these tech sessions......power windows.....ZF......shocks....

Seems like I worked on everything on the car....at a low altitude at these tech sessions......power windows.....ZF......shocks....

Cheers!!!

Steve

Attachments

...maybe Lancia Fulvia is not a bad start--at least, I remember all other A-arms (for the fiats here) were stamped steel--so no critical fit....but I see the Lancia Fulvia has something of a cup on an a-arm made of tube...

Attachments

...and the miracle, he has 6 of them. As I can tell, the ones that should seem to fit come in ones or twos...looks like a winner.

If these are the "sandwich type" with the steel top piece that busts out before you have 30K miles on the car.....I'd keep looking.......!

IMHO,

Ciao!

Steve

Sorry, I was looking for a replacement that looks like the original…

I guess it may be me that is over thinking this...... Ultimately it's up to the owner to decide what and how to build his car. I forget that the looks of something can mean a lot....I should know that as I sell parts for other vehicles based on the fact that they are and look like the proper parts!

I drove my car a lot......(miss it a lot....) and when pieces fell out of the a-arm when I removed them (both sides!), I was shocked! It was literally one good bump away from who know what kind of a "hold my beer" moment. But seriously, it was bad enough that the early cars were known for simply busting the ends of the a-arms off completely! Hence the two-three different revisions as time went on! To have the ball joints self destruct doesn't give me a feeling of confidence. I guess that was the cautious safety inclined me.

But today, as the values of these cars has skyrocketed, I can understand where actual original parts have a place in a car that will likely only see road duty on and off of a truck/trailer and around the grounds of a car show. ![]()

Carry on!

Kind regards,

Steve

@mangusta posted:I guess it may be me that is over thinking this...... But today, as the values of these cars has skyrocketed, I can understand where actual original parts have a place in a car that will likely only see road duty on and off of a truck/trailer and around the grounds of a car show.

Carry on!

Kind regards,

Steve

very true… and while the owners try to preserve the value of the car - at the same time they’re killing the car by not driving it!!

my car did 80 miles in 10 years. I had to replace or overhaul everything front to rear.

you don’t use it - you lose it!

Regarding the BJ .. I had some time to kill waiting… so I thought I help searching.. getting pretty good at it if I may say so (lots of practice with weird cars)

Thanx for data on ball joints. Have first set I ordered on ebay, and am waiting for second set to arrive.

Out of curiosity, if I am actually able to get the 4 bolts out of the hub and then am able to separate the hub from disc, how hard can I expect it to be it be to get the inner/outer bearings and seals out? Will the two seals be easy to find? Looks like the bearings are available after going through forum.

Once you get those nuts off of the spindle, all will be easier than if you don't!! ![]()

Seal number: 4117608 Fiat 1300 and many many many more. This too is info found on this site! Hello Moderator! We need stickies!!!

Cheers!

Steve

Ordered the following parts from Spareto in Estonia and they fit:

Ball Joints - TRW JBJ306 (FYI...4 ball joints for total of $40.72...shipping was additional $37.81)

Tie rod end - Delphi TA650 (FYI earlier order...2 tie rod ends for total of 10.12 Euros; clutch slave for 9.26 euros; 2 of the steering rack gaiters for total of 4.30 euros; 4 of the wrong ball joints (Delphi )TC76 for 27.96 euros...shipping for all was 39.64 euros...on this order forget to select $ for payment)

Have now ordered from them three times with zero issues. I ordered the TRW ball joints from them on 21 May and then added a hard to find relay for different car on 22 May. I received this order at noon today via DHL.

wrt to hub on disc again...have been looking at this hub/disc topic online. If I can get those 4 bolts out of hub holding it to disc, online shows quite a few nightmares about getting hub off disc. Are mechanics such on the Goose that this issue will not occur between spindle, disc, and hub?

When "staking" end of spindle as discussed earlier, attached pic looks like previous folks doing wheel bearing replacement simply "squeezed nut" to fill indents on bolt end of spindle vs using a cotter pin. Not having done a wheel bearing job before, is this an acceptable approach or should a cotter pin always be used?

Attachments

MJ,

You are looking at state of the art Italian technology here!!!!! ![]()

No cotter pins required or used or have the provision for it.....only new nuts...... Use a nail to release the nuts from the spindle....watch out for the threads......

I used cotter pins only because I drilled holes in my spindles....gonna save the world......! Did not take into account how deeply hidden the holes would be in the hub!!! Had to pre-curve or arc the pins in order to get them in and out easily.........

Order extra nuts....they are cheap....... See LeeA, he's the nut dealer! ![]() )))

)))

Steve

Thanx...searched the forum and found these various numbers for the wheel bearing job so they are all in one place:

front wheel bearings Timken LM67048, LM67010, LM11949, LM11910

Front seals 4117608 (??? how many)

Front nuts 14044871 (right front), 14044171 (left front)

Since I haven't gotten the hub off yet, not sure just how the bearings and seals (or how many seals there are) are arranged in Hub. Was able to get three of four of the hub bolts out, with one being stubborn, and am soaking the last bolt longer in kroil oil. Lot of rust on those bolts, glad they didn't snap off. Was able to create a solid base to brace hub by putting for nuts on the lug bolts, turning the hub upside down in a vice tightened to the 4 nuts on the lug bolts, and then unbolted the bolts holding the hub.

Ended up drilling out fourth hub bolt and knocked off head...will address remnants left in disc on thread when I get hub and spindle/disc separated. With that in mind, for the front left spindle, does the nut turn clockwise to tighten/counterclockwise to loosen? or is it a reverse nut?

Also, given hub nut pic above, managed bend screwdrivers try to push out the crushed part to no avail. Is best way to cut the crushed part with a chisel?

NAIL!!!

No chisels, no screwdrivers....... maybe, perhaps, possibly use a skinny center punch to push out the staked material. DO NOT deform the grooves and threads.....you'll hate life....or you'll need a LH thread reforming tool!

I forget which side is LH..... look closely at any exposed threads and read them.

Also NUT may have stake marks on all 6 points indicating it is LH.....

See Lee's pic that he posted a few posts back for the difference!!!

Steve

Yes, one side of the stub axle big nut is reversed thread! Look closely at the left side stub axle threads...amazing how much easier it is to remove the nut when you think righty-loosy lefty-tighty...

![SteveL[1] SteveL[1]](https://pantera.infopop.cc/fileSendAction/fcType/0/fcOid/1598208419924711/filePointer/26812249033097219/fodoid/26812249033097214/imageType/SQUARE_THUMBNAIL/inlineImage/true/SteveL%5B1%5D.jpg)