My wheels, PIM Campi clones, were on the car when I bought it 11 years ago. The center bore for the hub was machined at ~2.638", 67mm. The hubs on the car measure ~2.425", 61.6mm. Without concentric rings they are lug-centric. To top it off the wheels were supplied with the wrong style lug nuts, in my opinion. They were supplied with standard tapered seat lug nuts but should have been supplied with tapered seat with shank style lug nuts. Without the shank style lug nuts the wheels were centered only by the taper. I solved the issue years ago by purchasing the correct style lug nuts. Still, it was not ideal so it became one of those projects I eventually would get around to. It takes me quite a while to get to things these days but I finally made time to get to this one.

Pictures below:

Wrong Lug nuts that were supplied with the wheels:

Correct style lug nuts for the wheels the shank takes up the slop between the stud and the hole in the wheel:

I cannot find a picture of the wheels before I installed the concentric rings. If I do, I will edit and paste it in here.

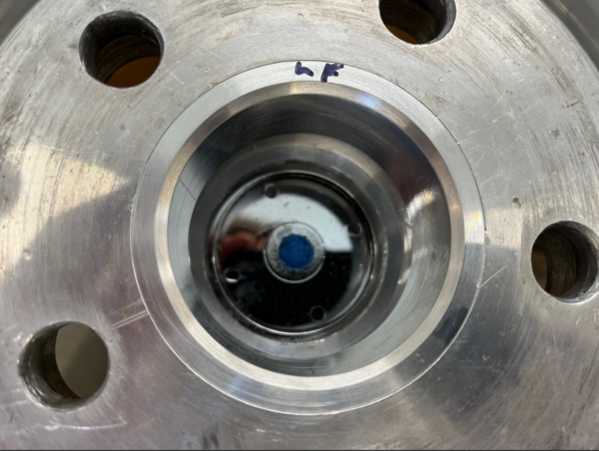

Wheels with concentric rings installed. I didn't take pictures of the rears, but it was the same story:

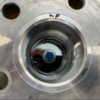

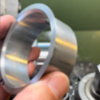

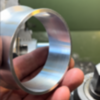

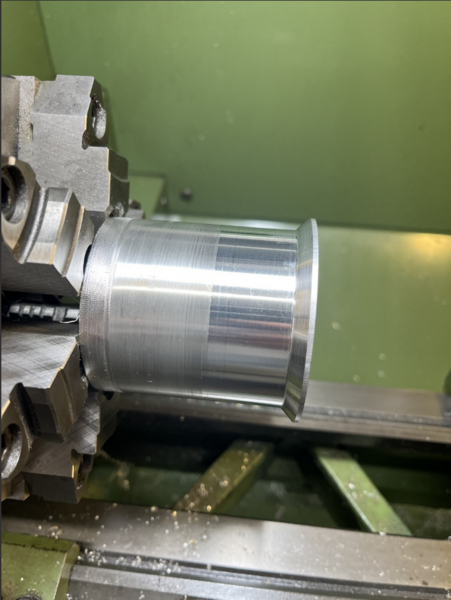

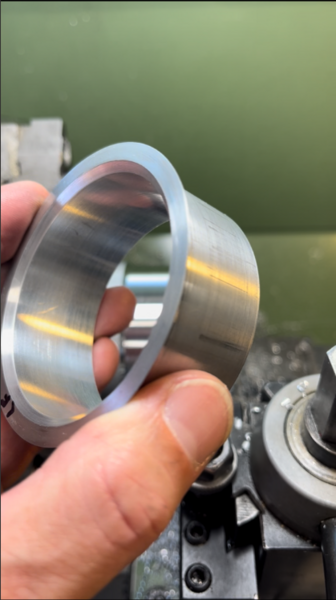

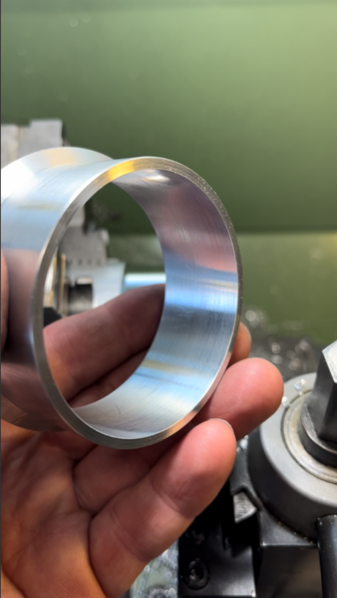

Making the rings:

Before the rings were installed, I had to fight to get the lug nuts on sitting on the ground, holding the wheels up with my legs until I could get 2 lug nuts somewhat aligned and run on so the wheel would rest on the shanks of the lug nuts. Now, I put the wheels on and spin the lug nuts on with little effort because they are perfectly lined up.

Steve