I can't answer about the cable function because I simply would never engineer one like that.

I would use a bell crank.

I do think that it is highly likely that is where you binding takes place.

Just pull the fuel rails appart and change the o rings. That's all that is in there. Nothing fancy.

You have to be running around 40 psi for fuel injection, so even just a drip isn't going to remain a drip for long.

I have flooded the intake manifold with fuel ON A HOT ENGINE! I saw my entire life pass me in just a micro instant.

The fumes took at least 100 points off of my IQ permanently. Now I am left with less than 1/2 of a brain, which I am sure surprises no one?

You DO NOT WANT TO EXPERIENCE that. It is at least 10 years off of your life.

mike the snake (Guest)

OK, well that's good to hear.

I can take stuff apart no prob, been doing that since I was a wee tot. It's getting it all back together that's often the hard part.

I'll take the fuel rail off and fix that. Fuel pressure runs around 42 I believe. I just noticed the raw fuel around the cable guide today, as I started chasing the throttle cable issue today.

BUT, since now it's gonna be a pull the seats and firewall and remove the cable ordeal, along with repair of the fuel rail, once again it's gonna be a while before I get to enjoy driving Snow White (it's actually not that much work, just sucks to do it alone).

We're still within the realm of stuff I can do myself, it's down to motivation and interest now. I'm getting tired of working on the car.

Might just take a break for a while

I can take stuff apart no prob, been doing that since I was a wee tot. It's getting it all back together that's often the hard part.

I'll take the fuel rail off and fix that. Fuel pressure runs around 42 I believe. I just noticed the raw fuel around the cable guide today, as I started chasing the throttle cable issue today.

BUT, since now it's gonna be a pull the seats and firewall and remove the cable ordeal, along with repair of the fuel rail, once again it's gonna be a while before I get to enjoy driving Snow White (it's actually not that much work, just sucks to do it alone).

We're still within the realm of stuff I can do myself, it's down to motivation and interest now. I'm getting tired of working on the car.

Might just take a break for a while

Fix the access panel to the engine. Make it removable without taking out the entire panel or the seats.

mike the snake (Guest)

Do most people do away with the big metal cover, and just mod their upholstery hump so it velcros or snaps in place?

mike the snake (Guest)

Yes, I believe it's something like that.

quote:Originally posted by JFB #05177:

MtS, I am trying to visulize your linkage. does this look like it?

quote:Do most people do away with the big metal cover, and just mod their upholstery hump so it velcros or snaps in place?

I can't speak for most people, but I don't thing most people are running without the metal panel.

I have a flattened metal bulkhead cover. Now you can't just "make one" - it requires some mods to "outboard" your alternator, and maybe your A/C Compressor.

The "hump" on the big fiberglass panel is (one of) my next project(s).

Just to torment everyone (and to show off the work of my friend and mentor, Wade - a.k.a MarkIV/4280), I will post up another link to my build thread. If you scroll about 1/2 way down, you can see the flat bulkhead modification. On page 4 of the thread, right at the top, you will see pictures (and discussion of) the outboarded alternator and Sanden Rotary A/C compressor on the engine before we installed it.

Now I need to make the fiberglass cover match the profile of the inner hump, and make the outer "hump" removable with Velcro.

Once this is done, my passenger gets about 3" more legroom and/or recline, and I get easier access to the front of the engine bay.

Scroll About 1/2 Way Down to See the Flat Metal Bulkhead...

I recommend you also look at page 6 (down at the bottom) - there is more pix, and a like to David Nunn's setup.

This is how we did it - I am sure there are other ways to skin this cat.... (get it?)

Rocky

I would not get rid of the metal cover. Not only is it your firewall, but offers some protection from flying objects.

MtS,

I am curious and would like to learn something about an IR setup, so I'll have some questions.

Is the "idle" speed set by adjusting the opening of the butterfly plate and balancing air flow?

IF so,

is the butterfly opening a "stop" adjustment on each shaft?

is the linkage disconnected when setting idle to ensure it does not hold a butterfly off its idle stop?

when you get a chance, a photo showing the detail of the rod end bearing's connection to the throttle shaft arms would be nice

I am curious and would like to learn something about an IR setup, so I'll have some questions.

Is the "idle" speed set by adjusting the opening of the butterfly plate and balancing air flow?

IF so,

is the butterfly opening a "stop" adjustment on each shaft?

is the linkage disconnected when setting idle to ensure it does not hold a butterfly off its idle stop?

when you get a chance, a photo showing the detail of the rod end bearing's connection to the throttle shaft arms would be nice

mike the snake (Guest)

I'll gladly take more pics, but there are many adjustment screws. I have an OK idea as to what each screw does.

I do believe there's an adjustment stop on each body, and also a main idle adjustment screw as well.

Some of the screws are to balance between the front and rear pair of IR's, I believe the cross shaft adjusts the balance between the two sides, and there's a main idle adjustment somewhere as well.

I started to try and make sense of it, but all the holes showed so close with my unisync flow tool that all I touched was (what I think was ) idle, and it was so sensitive, i put it back where it was and decided when thwe time came I'd throw the car at someone who knew their way around these systems.

I also need a tune BAD, but my Haltech is ancient, and I need to find a program that makes a newer computer appear to be running DOS so it can communicate with the Haltech, then a tuner acn make adjustments.

THEN I need to find a tuner who knows his way around tuning IR systems like this.

This is plan A.

If enough time goes by, or I can't keep the car running, I'm going to wait and save and upgrade to newer electronics and tune that controls both ignition and fuel. This is Plan B, but that won't happen until after I rebuild the engine.

I do believe there's an adjustment stop on each body, and also a main idle adjustment screw as well.

Some of the screws are to balance between the front and rear pair of IR's, I believe the cross shaft adjusts the balance between the two sides, and there's a main idle adjustment somewhere as well.

I started to try and make sense of it, but all the holes showed so close with my unisync flow tool that all I touched was (what I think was ) idle, and it was so sensitive, i put it back where it was and decided when thwe time came I'd throw the car at someone who knew their way around these systems.

I also need a tune BAD, but my Haltech is ancient, and I need to find a program that makes a newer computer appear to be running DOS so it can communicate with the Haltech, then a tuner acn make adjustments.

THEN I need to find a tuner who knows his way around tuning IR systems like this.

This is plan A.

If enough time goes by, or I can't keep the car running, I'm going to wait and save and upgrade to newer electronics and tune that controls both ignition and fuel. This is Plan B, but that won't happen until after I rebuild the engine.

mike the snake (Guest)

Ok, i"m trying to address the sticky throttle and leaky fuel rail.

The rail leaks between the two halves, that are joined by a smaller diameter tube.

This tube spun easily with my fingers, so the O-rings must be old.

There's a plastic retainer tab on each side of the center tube, with a screw.

I'm wondering if this tube can be removed and O-rings replaced without having to completely dismantle the entire fuel rail.

Maybe the plastic retainer will allow the center tube to slide inside one half enough to allow the new O-rings to be installed, and then the same done to the other side, and then the plastic retainers keep it all centered somehow?

The rail on the other side seems to be extruded or soldered or made into the main part of the rail at least on one side. I didn't look as closely at that side as it wasn't the side that was leaking.

The rail leaks between the two halves, that are joined by a smaller diameter tube.

This tube spun easily with my fingers, so the O-rings must be old.

There's a plastic retainer tab on each side of the center tube, with a screw.

I'm wondering if this tube can be removed and O-rings replaced without having to completely dismantle the entire fuel rail.

Maybe the plastic retainer will allow the center tube to slide inside one half enough to allow the new O-rings to be installed, and then the same done to the other side, and then the plastic retainers keep it all centered somehow?

The rail on the other side seems to be extruded or soldered or made into the main part of the rail at least on one side. I didn't look as closely at that side as it wasn't the side that was leaking.

Attachments

mike the snake (Guest)

Here's another pic of the plastic retainer, with the screw that holds it in place.

The center tube spins easily by hand, and seeps fuel, so the O-rings need replacing.

I'm just wondering if it can be done without removing the whole rail system, or if the center tube can be slid back and forth enough to remove and replace the new O-rings.

The center tube spins easily by hand, and seeps fuel, so the O-rings need replacing.

I'm just wondering if it can be done without removing the whole rail system, or if the center tube can be slid back and forth enough to remove and replace the new O-rings.

Attachments

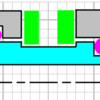

do you think the fuel rail is off the shelf or custom made. Just looking at the photos, both the tube and the rails look thin to have an oring seal. I would invision that the oring could be installed either of two ways. and I would expect the tube could be slide to allow acces to one end at a time. I would hope the oring would be on the OD of the tube as trying to hoke out one from the ID of the rail would be dificult with the limited access

I would say try

I would say try

Attachments

How do you plan on getting a screwdriver in to undo those screws ?

Take the entire rail off.

Replace all the orings.

Take the entire rail off.

Replace all the orings.

I think the tube is probably flared on each end and sits into a machined inverted flare seat similar to a Holley carb with a tube nut.

There is no compression fitting because the mounting of either extrusion is held firmly in place by the mounting to the injectors and there are probably mounting tabs on each extrusion as well that bolt at some point to either the throttle bodies or the manifold.

I looked for details on that particular rail but don't see any.

If you get stuck on something try Dennis at Colorado Pantera Performance. He most likely did the original design on the system.

The Byers brothers at Precision Proformance probably know as well.

Neither of these guys like to post details like this on the internet.

I personally would remove them both of the rail assemblies and replace all of the orings in the assembly.

They are highly likely just off the shelf items you can get at any auto parts dealer in the "o-ring" assortments variety packs.

Here is where you get to use that little ratcheting 90 degree screw driver to get those screws out. If you happen to strip them, then you will discover why people use a torqs head bolt in there?

It should not be a major ordeal.

There will be a short learning curve.

Those fuel rails look like the REDLINE fuel rails.

http://www.carburetion.com/Weber/wildv8injection.asp

There is no compression fitting because the mounting of either extrusion is held firmly in place by the mounting to the injectors and there are probably mounting tabs on each extrusion as well that bolt at some point to either the throttle bodies or the manifold.

I looked for details on that particular rail but don't see any.

If you get stuck on something try Dennis at Colorado Pantera Performance. He most likely did the original design on the system.

The Byers brothers at Precision Proformance probably know as well.

Neither of these guys like to post details like this on the internet.

I personally would remove them both of the rail assemblies and replace all of the orings in the assembly.

They are highly likely just off the shelf items you can get at any auto parts dealer in the "o-ring" assortments variety packs.

Here is where you get to use that little ratcheting 90 degree screw driver to get those screws out. If you happen to strip them, then you will discover why people use a torqs head bolt in there?

It should not be a major ordeal.

There will be a short learning curve.

Those fuel rails look like the REDLINE fuel rails.

http://www.carburetion.com/Weber/wildv8injection.asp

They’re TWM (now Borla) throttle bodies of the same era as your Haltec ECU. The fuel rail kits were standard items and the old TWM website use to have an exploded view and illustrated parts reference that called out each fuel rail part by number. I don’t believe the new site has this reference or if it does, I could never find it. In fact, though Borla have large bore IDA TBs listed, I’m not even sure they list the 48/50mm IDA style TBs anymore, but they do offer them on their “V-8 systems” which still have similar style modular fuel rails.

The next generation of their hardware used similar modular rails but the rails were mounted inboard and the ends had modular caps that tied the rails together and also allow mounting of other components such as regulators, gauges, sensors, etc.

That tube in your picture just has O-ring seals to each fuel rail and floats between the two rails so as to accommodate intakes with different center line distances between TBs.

Just replace the O-rings. It’s a 15-30 minute job to remove the rails, measure and buy a couple 25 cent O-rings. If you remove the two underside screws that mount each fuel rail, both rails on the bank will lift off the injectors and then use an offset or ratchet screw driver to remove the inside retaining caps. –Replace O-rings reverse assembly.

K

The next generation of their hardware used similar modular rails but the rails were mounted inboard and the ends had modular caps that tied the rails together and also allow mounting of other components such as regulators, gauges, sensors, etc.

That tube in your picture just has O-ring seals to each fuel rail and floats between the two rails so as to accommodate intakes with different center line distances between TBs.

Just replace the O-rings. It’s a 15-30 minute job to remove the rails, measure and buy a couple 25 cent O-rings. If you remove the two underside screws that mount each fuel rail, both rails on the bank will lift off the injectors and then use an offset or ratchet screw driver to remove the inside retaining caps. –Replace O-rings reverse assembly.

K

Mike,

Here's the link to the appropriate page on Borla Induction's web site. It's interesting that they still use TWM part numbers.

http://www.borlainduction.com/fuel-rail-kits.html

Here's the link to the appropriate page on Borla Induction's web site. It's interesting that they still use TWM part numbers.

http://www.borlainduction.com/fuel-rail-kits.html

quote:Originally posted by Panterror:

...Just ... a couple 25 cent O-rings..

ain't that what Morton Thiokol said

It depends on what a "dime" is to them. Here it most often is $100,000, to a Contractor.

Them? Probably a dime is a million. They cant calculate smaller.

Them? Probably a dime is a million. They cant calculate smaller.

I was referring to an improper choice of material/size for a 25 cent oring can have significant consequences.

Add Reply

Sign In To Reply