http://www.spacecitypanteras.c...Cooling-JTaphorn.pdf

Is there a parts list with part numbers for this modification?

Replies sorted oldest to newest

quote:Originally posted by No Quarter:

Isn't the main reason that coolant or water on a car doesn't boil at 212F that it's under pressure? If a hose bursts it can quickly boil?

quote:Originally posted by tajon:

Would like to see the one tank method.

quote:Or.......

You could keep the stock system design, perform normal maintenance, replace failing components with quality replacements and somehow still manage to have a perfectly functional system that gives fine performance year after year..... just as hundreds and hundreds of Pantera owners are still doing.

Larry

quote:if you are considering making revisions to the coolant system plumbing then increasing the size of the radiator outlet plumbing to 1-3/4" OD is where to begin your effort.

quote:

Originally posted by "72 GTS:

... I'll fit 180°headers, and then need to relocate the tank ... I read somewhere that I would only need one tank ...

quote:

Originally posted by Mat_G:

... where is the cross over from 1 3/4 to 1 3/8 then ...

quote:

Originally posted by Mat_G:

... THEN the Thermo switch needs on the HOT side (assume now lower side) ...

Install aluminum heatsink through the entire length of the cooling lines 8 feet long in large sections. Sold on Alibaba. Replace antifreeze to glycol based non-diluted "orange" type. Install a small oil cooler with a fan in to the rear pas. wheel-well steel shroud by cutting a window in it for the cooler

It's interesting that John Taphorn's remote thermostat cooling mod. is more widely accepted in the GT40 replica world than it is in the Pantera world. Perhaps that's because GT40 replica builder's are starting with a clean slate, rather than modifying a production car.

John's logic is sound. In an automotive cooling system, coolant flow is the most important factor. The greater the coolant flow, the more efficiently the cooling system functions. In a Pantera, the effect is, less chances of hot spots in the cylinder heads and greater ability to dissipate heat. A Pantera with this mod. is more likely to have a steady coolant temp., as opposed to a coolant temp. that rises and falls. Unfortunately, in a Pantera you can't simply increase water pump speed to increase coolant flow, due to cavitation.

https://www.alibaba.com/produc...image.2d9513a0Gr5TZ2

If you incapsulate long pipes in some of the stuff these people sell it's like adding another massive radiator. Just remember, removing thermostat for faster circulation through this modification will be counterproductive. Antifreeze will not be able to cooldown sufficiently enough going thorough pipes faster. However, it will be cooled on the way out and cooled even more on the way in. You can also install small rubber baffles in the heatsink gills every several feed or so to capture incoming coder air from down below. Old 911 Porsches have rubber baffles under the car for the air cooled engine shroud.

@mikebux posted:https://www.alibaba.com/produc...image.2d9513a0Gr5TZ2

If you incapsulate long pipes in some of the stuff these people sell it's like adding another massive radiator. Just remember, removing thermostat for faster circulation through this modification will be counterproductive. Antifreeze will not be able to cooldown sufficiently enough going thorough pipes faster. However, it will be cooled on the way out and cooled even more on the way in. You can also install small rubber baffles in the heatsink gills every several feed or so to capture incoming coder air from down below. Old 911 Porsches have rubber baffles under the car for the air cooled engine shroud.

Keep in mind, that dissipated heat needs to go somewhere. If the car's moving, most of it goes out the back but if it's stopped, that heat will radiate up into the passenger compartment.

Somehow, I have to disagree with this whole coolant speed issue… In my mind, the coolant – Water has to stay in contact with the Engine for some time to take on the heat and then it gets transferred to the radiator, which has to be there for some time to get cooled down by the airflow..

I do not see that a lot of coolant is rushing very fast through the engine removes a lot of heat!

same holds true the other side – radiator!

I think this is one of the few cases where speed is not the answer!

My previous post made a similar point regarding the speed of circulating antifreeze.

@LeMans850i posted:Somehow, I have to disagree with this whole coolant speed issue… In my mind, the coolant – Water has to stay in contact with the Engine for some time to take on the heat and then it gets transferred to the radiator, which has to be there for some time to get cooled down by the airflow..

I do not see that a lot of coolant is rushing very fast through the engine removes a lot of heat!

same holds true the other side – radiator!

I think this is one of the few cases where speed is not the answer!

I always felt the same way you do, until I spent an hour on the phone with an engineer at Stewart Components. Stewart is a cooling system technology/engineering firm. They supply water pumps to NASCAR. It's all here:

https://www.stewartcomponents.com/about/

Pay attention to the part about multi-pass radiators!

There is a law of physics that says that the amount of heat transferred is roughly proportional to the flow rate of the heat transfer fluid. So the more flow rate, and therefore the more speed, the more it cools.

The misconception is that it takes time for heat to transfer from coolant to the air when passing through a radiator. It does, in fact, take a fraction of a second. Mind you, the biggest reason to increase coolant flow in a Pantera is to reduce cavitation. Even in a perfectly sealed cooling system, cavitation creates air bubbles. Hot spots create air bubbles too. The single biggest improvement a Pantera owner can make would be switching to a single pass rad. It doesn’t really matter whether the inlet is at the top or bottom right but the outlet would be at the opposite corner. The most conventional configuration would be the inlet at the top right and the outlet at the bottom left, just like 99% of production cars. I had mine built by Ron Davis and they were in 100% agreement that all Pantera rads should be single pass. I asked, if that’s the case, why they make double pass rads at all? Their response was, because that’s what Pantera owners want. An added benefit of a single pass rad is, with the inlet/outlet at the corners, 14” fans fit easily. Bigger fans are good to have if you relocate the A/C condenser to the front. Most Pantera’s with lay forward rads and sucker fans use 12” fans.

David, I have to disagree with your statement "cavitation creates air bubbles". Cavitation is the formation and subsequence collapse of VAPOR bubbles as a fluid flows from the low pressure in the eye of the impellor where the bubbles form, along the vanes where the pressure increases and the bubbles collapse, to the volute. The bubbles collapsing can impart thousands of pounds of pressure (depending on the system) which causes the noise and damage to the vanes.

@husker posted:David, I have to disagree with your statement "cavitation creates air bubbles". Cavitation is the formation and subsequence collapse of VAPOR bubbles as a fluid flows from the low pressure in the eye of the impellor where the bubbles form, along the vanes where the pressure increases and the bubbles collapse, to the volute. The bubbles collapsing can impart thousands of pounds of pressure (depending on the system) which causes the noise and damage to the vanes.

I’m only relaying what I was told by Stewart but perhaps I misunderstood the “air bubbles” issue. I will defer to you on this one!

Just to add, in a closed system if you maintain the system pressure greater than the low pressure necessary to form the vapor bubbles cavitation won't occur.

@husker posted:Just to add, in a closed system if you maintain the system pressure greater than the low pressure necessary to form the vapor bubbles cavitation won't occur.

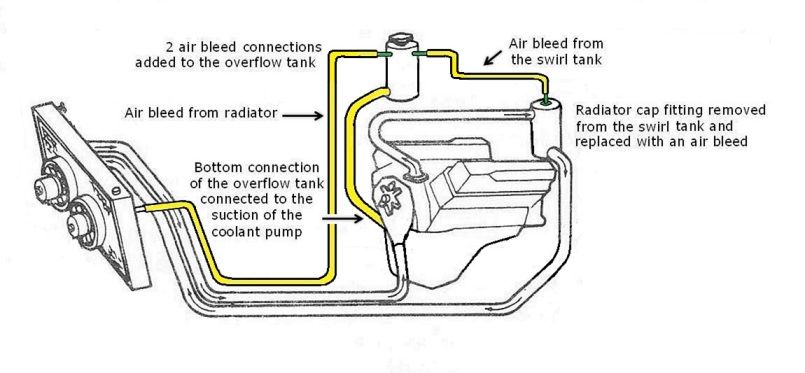

the original arrangement placed the pressure setting cap on the swirl, thus the pump discharge. It would be a fair guess that this has the pump suction at 0 or even vacuum (reducing the boil point below 210f

the modifed arrangment moves the pressure setting cap to the pump suction.