As I continue working on my Pantera, I'm also considering the rarity and availability of some of the parts for this car. For example, the "electronic" part of the ignition switch itself is considered an incredibly rare piece that is difficult to find and sometimes fairly expensive when they do come up. Should this piece fail entirely, someone's going to be left with a non-running car if they can't find a replacement or rebuild theirs. As I continue making progress with the car, it's likely I'll find other parts that are simply not available anymore.

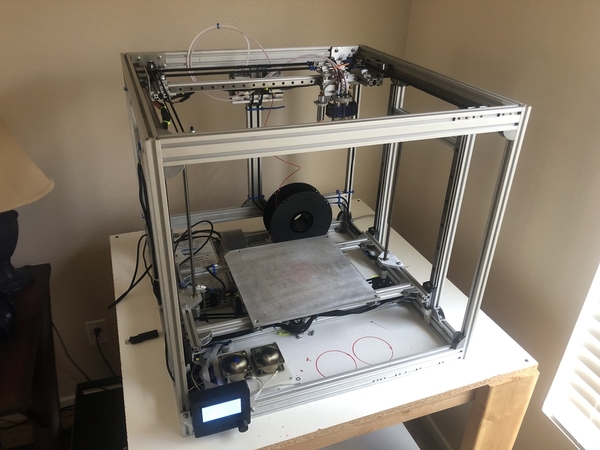

One of my side hobbies, other than working on rare Italian cars, is CNC machining and robotics. I've built from scratch, with no plans or blueprints, a complete 3D printer and a small CNC engraver for PCB milling. I am also somewhat fluent in Autodesk Inventor and Fusion360, making most of the plastic parts for my engraver using the 3D printer. I'm looking to get into slightly larger machining footprint and I wanted to gauge interest among the Pantera community here to see if there's any desire for my "reverse engineering" and prototyping replacement parts for these cars. I've been looking at the Tormach PCNC440 as a possible candidate for a benchtop CNC machine suitable for small to midsized parts.

One of the first things I am interested in doing is to reverse engineer and prototype a drop in ignition switch replacement, milling the housing from high grade aluminum and the plastic parts from Delrin or some other suitably strong plastic, and using copper and brass for the electrical bits. The idea here is to turn out a part that can be simply remounted to the original, factory Pantera mechanical ignition assembly and wired in.

So what does the community think about this? If I started prototyping parts, would there be any interest from folks in purchasing them? What are some other small to mid sized parts that folks would be interested in?