Start by cutting off the bushing holders as shown. I used a recipro saw, and belt belt sander to shape the angle.

Then.......... I would suggest tack welding these on first to make sure everything lines up cleanly, if you get the angle wrong the rod ends won't fit right in the bushing holders and you may need to knock them off and sharpen or lessen the angle. Again, belt sander works well for this.

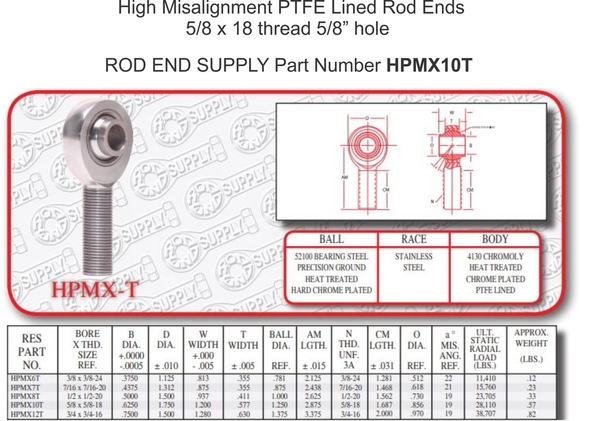

Get these or equivalent. Must be HIGH MISALIGNMENT

Now you need spacers to fit between the bushing holders and rod ends. Because the hole in the rod end is 5/8, and the bolt is 12mm you're going to need these, that reduce the hole size. I got them on E-Bay. You need (8) total, and a variety. I would get (3) of the 1.75" (3) of the 1.50" and (2) of the 1.25" thick, but you won't use them all, explained below.

You also need (4) 5/8 x 18 jam nuts. The finished but not painted unit....

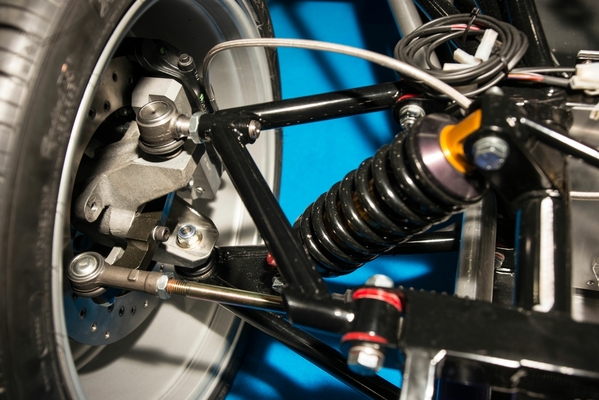

I was able to get a good tight fit on the passenger side using the spacer variety. I was not lucky on the drivers side and had to use one or two washers/shims, and internal bushings. I got these from ACE Hardware. The internal bushing on one side was needed to keep the 12mm bolt centered in the 5/8" hole. Which is what you'll need to do if you can't fit a spacer in there. I was really not pleased about this, and the only thing that kept the whole thing perfect.

The mocked up installation....

I will say this is not cheap, over $300.00 just in parts, but it's cheaper than over a thousand, and getting a product that you will still need to fiddle with spacers and possible machining to make fit.

Thanks to the members that chimed in over my frustration about this. Made me think, and take action. Also found an older picture of a modified set that helped.