And finally after months of downtime, the rear stablizer bar and lower control arms go back in.

OzGT5 (Guest)

Front and rear bumpers have been removed to make way for a set of the special short versions produced by Kirk Evans.

I ordered them before I took the car off the road back in April, but they haven't arrived yet. So looking forward to putting the car on the road minus the steel rear bumper and the 'shark' nose.

Fully rebuilt Alden shockers are here to go on along with full billet axles.

More pics over the next few days.

I'm a bit held up by the exhaust. I stripped everything back and recoated the system with a ceramic exhaust paint, but I wan't happy with the tips. The ANSA sticker had trapped moisture and dirt underneath and this damaged the chrome plating. Also there were some abrasions there that wouldn't polish out.

I had a local exhaust tech roll some 0.8mm stainless into a 70mm ID tube. He welded this over the original tips and then shaped the tube to perfectly match the original ANSA shape. I have the exhaust at a metal polisher today to highly polish the stainless tip covers. This should look perfect and allow me to look after them without the issues associated with chrome.

I ordered them before I took the car off the road back in April, but they haven't arrived yet. So looking forward to putting the car on the road minus the steel rear bumper and the 'shark' nose.

Fully rebuilt Alden shockers are here to go on along with full billet axles.

More pics over the next few days.

I'm a bit held up by the exhaust. I stripped everything back and recoated the system with a ceramic exhaust paint, but I wan't happy with the tips. The ANSA sticker had trapped moisture and dirt underneath and this damaged the chrome plating. Also there were some abrasions there that wouldn't polish out.

I had a local exhaust tech roll some 0.8mm stainless into a 70mm ID tube. He welded this over the original tips and then shaped the tube to perfectly match the original ANSA shape. I have the exhaust at a metal polisher today to highly polish the stainless tip covers. This should look perfect and allow me to look after them without the issues associated with chrome.

Yes, the ANSA sicker is a well known problem. I took them off mine when I first got the system years ago.

Mike

Mike

OzGT5 (Guest)

And here's where she's been sitting for the last few months. And now her stable mate is playing up too. Dropped a heap of power on the right bank of the engine.

Bloody Italians...........always something, and just when we are finally coming into some decent weather again!

Bloody Italians...........always something, and just when we are finally coming into some decent weather again!

Attachments

OzGT5 (Guest)

Today I built the rear hubs with my new billet axles. Lovely fit, just the right feel on the press when fitting the bearings. Right side may have been about a half of one poofteenth tighter, but both felt about right. These were Bob's axles from Proformance.

Hubs are now ready to fit to the lower arms, but still waiting on the exhaust as I'd like to fit this first and get it out of the way.

Whilst I'm waiting I thought I'd change that horrible rubber bush that the shifter linkage passes through. The one on the left rail under the headers. Bugger of a spot to get to!

I'm wondering if anyone has replaced this that could explain any tricks to getting the linkage off, gaining access to the two big nuts and then re-asembling without having to fully setup the shifter linkages again?

Any tricks to make this job a little easier?

Hubs are now ready to fit to the lower arms, but still waiting on the exhaust as I'd like to fit this first and get it out of the way.

Whilst I'm waiting I thought I'd change that horrible rubber bush that the shifter linkage passes through. The one on the left rail under the headers. Bugger of a spot to get to!

I'm wondering if anyone has replaced this that could explain any tricks to getting the linkage off, gaining access to the two big nuts and then re-asembling without having to fully setup the shifter linkages again?

Any tricks to make this job a little easier?

No tricks really, just a busted knuckle or two. I replaced mine with a Quella unit which gets rid of the rubber bushing.

OzGT5 (Guest)

I'm more wondering which linkages need to be loosened (removed) so I don't lose the shift adjustment as aparently that can be a bit of a PITA to reset.

I managed to get the 24mm nut off the base, so the unit is loose, now need to seperate the linkage and get it out.

I managed to get the 24mm nut off the base, so the unit is loose, now need to seperate the linkage and get it out.

Since you'll be taking off knuckle(s) I don't think there's anyway around not having to readjust the linkage. It is a bit of a PITA, easier with 2 people. The major issue I had was getting the splines cleaned up enough the knuckle could freely slide all the way in and out, much easier to do with all the parts out of the car.

Robert, are you angling the new exhaust tips up more than stock? Those tips run over 500 degrees- hot enough to melt solder- in a hard- driven Pantera. So the decals are usually short lived anyway. And the exhaust seems to get caught in the upward air blast around the rear of the car. One U.S GT-5 with short upturned tailpipe tips melted both his taillight lenses in a single 90 mile wide-open blast some years ago. There's also enough rear lift from that aero to spin the tires in 5th if you have the horsepower to run to 175 or beyond....

OzGT5 (Guest)

I've actually trimmed the sleeve to suit the exact shape of the original ANSA exhaust. If you look really closely you can just see the inner original, but it looks like a double laminate of steel tip. Maybe having no rear bumper to protect the lights could be an issue, but I'm stuck waiting on Kirk for that one.

I always wondered about the 'wing'. Does it provide downforce or lift? In my experience it's made wrong. It should have a cap or blade on each end of it to trap the air and force the car down. Not having ends on the wing makes it virtually cosmetic.

Another thing on my list for when I do up the bodywork is to modify the rear wing.

I always wondered about the 'wing'. Does it provide downforce or lift? In my experience it's made wrong. It should have a cap or blade on each end of it to trap the air and force the car down. Not having ends on the wing makes it virtually cosmetic.

Another thing on my list for when I do up the bodywork is to modify the rear wing.

There is a July 1985 Fast Lane GT5 review article where they tested the car with and without the wing. They found no loss of performance without the wing and picked up some MPH on top end.

They recommended ordering the car without the wing.

Mike

They recommended ordering the car without the wing.

Mike

quote:I'm wondering if anyone has replaced this that could explain any tricks to getting the linkage off, gaining access to the two big nuts and then re-asembling without having to fully setup the shifter linkages again?

I did mine without loosening the large adjusting nuts. I was able to separate the u-joint from the splines. But, as Husker pointed out, this can be difficult unless the splines are clean.

If you can separate at the splines, then the only adjustment that you will have to make is the fore/aft position of the shifter. This can be done by loosening the "pinch" bolt on the shift shaft u-joint. Just make sure that the splines are returned to their original "location".

If any of the shifter u-joints feel rough, the ones from Flaming River are a less expensive replacement than the originals.

http://pantera.infopop.cc/eve/...=890103126#890103126

John

OzGT5 (Guest)

Thanks John,

I undid both of those pinch bolts close to the bush and as you said I was able to tap them forwards and release the long linkage, and then slide the bush off. I marked the knuckle and spline with a bit of tippex before I removed it so the splines went back on the same. I've now done both bolts up and went to check, but neutral is now too far forward and I cant shift into r/1 because of this.

I take it that by pinch bolt, you mean the one closest to the new bush, release that and maybe get someone to hold the stick in the centre and then do it up?

I undid both of those pinch bolts close to the bush and as you said I was able to tap them forwards and release the long linkage, and then slide the bush off. I marked the knuckle and spline with a bit of tippex before I removed it so the splines went back on the same. I've now done both bolts up and went to check, but neutral is now too far forward and I cant shift into r/1 because of this.

I take it that by pinch bolt, you mean the one closest to the new bush, release that and maybe get someone to hold the stick in the centre and then do it up?

Robert,

The pinch bolt is the bolt and nut that clamps the u-joint to the splined shaft. If you loosen the pinch bolt, you should be able to slide the splines to get the fore/aft adjustment that you need.

John

The pinch bolt is the bolt and nut that clamps the u-joint to the splined shaft. If you loosen the pinch bolt, you should be able to slide the splines to get the fore/aft adjustment that you need.

John

Regarding your Aldan shocks.

There was some conversation about Aldans and seal leaks on the email forum a little while back.

The culprit seems to be over tightened mounting bolts and/or a slightly too short steel bushing causing the urethane bushings to bind on the shock body that in turn stresses the shaft seal.

There was some conversation about Aldans and seal leaks on the email forum a little while back.

The culprit seems to be over tightened mounting bolts and/or a slightly too short steel bushing causing the urethane bushings to bind on the shock body that in turn stresses the shaft seal.

OzGT5 (Guest)

Hmm... that's interesting as three out of four of my shocks came back with shafts replaced because they were bent and this is what had caused the gas to escape.

When I put the new ones in I'll check them for swing top and bottom before I final fix them.

Basically, if they dont pivot freely from both top and bottom mounts without binding at all, then they are too tight and I may need to space the central tube?

When I put the new ones in I'll check them for swing top and bottom before I final fix them.

Basically, if they dont pivot freely from both top and bottom mounts without binding at all, then they are too tight and I may need to space the central tube?

OzGT5 (Guest)

I just figured out that 420 ft/lbs is horribly bloody tight!!

But.......my home made tool stood up to the test and all looks good.

But.......my home made tool stood up to the test and all looks good.

OzGT5 (Guest)

Well I hope you guys had a better day than me.

As mentioned in an earlier post, I had built the hubs and were ready to fit them to the car. When pressing the new axles into the captive outer bearing (installed into the hub) I did notice that the RHS bearing took a little more pressure on the press than the left but it didn't feel too bad and when the spacer tube, inner bearing and the flange went on, it rotated nicely and didnt seem to be a problem.

This morning I tightented the nuts. 250 / 300 / 350 ft lbs. Left side, all went perfect, but right side, the tension wrench wouldn't click at 350, it seemed to want to keep tightening.

I stopped to check things out and found that the hub had siezed up and I couldn't rotate the disc anymore.

I can't explain why, it's exactly the same as the other side, but something is amiss.

As mentioned in an earlier post, I had built the hubs and were ready to fit them to the car. When pressing the new axles into the captive outer bearing (installed into the hub) I did notice that the RHS bearing took a little more pressure on the press than the left but it didn't feel too bad and when the spacer tube, inner bearing and the flange went on, it rotated nicely and didnt seem to be a problem.

This morning I tightented the nuts. 250 / 300 / 350 ft lbs. Left side, all went perfect, but right side, the tension wrench wouldn't click at 350, it seemed to want to keep tightening.

I stopped to check things out and found that the hub had siezed up and I couldn't rotate the disc anymore.

I can't explain why, it's exactly the same as the other side, but something is amiss.

OzGT5 (Guest)

So I removerd the nut and the flange and then removed the hub from the lower control arm, knowing that I'd need to press it all apart and take a look. Strangely enough, my press wouldn't shift it.

I ended up having to take it to a local workshop with a serious 100 tonne press and have them do it. Obviously the fact that t was late on a Friday afternoon and the operator wanted to go home and attend to some serious weekend drinking, I don't think he took the care that he should have, and he ended up smashing my rotor!!

Can anyone imagine what that felt like. Here I am on the other side of the World, three days away from driving my car which has been on the hoist for 6 months, and I need a new rear rotor.

Pantera rotor in Australia is about as rare as golden rocking horse sh!t, and no local brake places were able to come up with a solution.

When I got home and got the rest of the bits cleaned up, I noticed really heavy scoring in my nice new axle shaft. inside the larger (outer) bearing there is also really bad scoring, yet this was a brand new bearing onto a brand new axle. Fitted up with a liberal smearing of grease to help the fit, but it's really quite bad.

So here's a couple of interesting questions?

1. Bob's axles are beautifully finished to a very exacting tollerance. The bearing was a new USA manufactured bearing yet somehow I ended up with serious scroing on the axle shaft. How can this be?

2. Why couldn't I get the tension wrench to 'click' at 350lbs like I could on the other side?

3. When first fitted, the rotor turned fine, but when the tesnion of 300 lbs went onto the hub nut I was not able to rotate the disc anymore. I don't get this as you have the axle, then the spacer cup, then the bearing, spacer tube, inner bearing, flange, washer and nut. There isn't anything else and both sides are the same, yet one has 350ft/lbs on it and rotates freely and the other bound up!

Now, for standard rear solid rotors, who is best to get these from?

I see Wilkinsons lists three rotors. One solid, one vented, and one vented GT5.

Will both of the first two fit my car, or do I stick with the solid that it had?

I ended up having to take it to a local workshop with a serious 100 tonne press and have them do it. Obviously the fact that t was late on a Friday afternoon and the operator wanted to go home and attend to some serious weekend drinking, I don't think he took the care that he should have, and he ended up smashing my rotor!!

Can anyone imagine what that felt like. Here I am on the other side of the World, three days away from driving my car which has been on the hoist for 6 months, and I need a new rear rotor.

Pantera rotor in Australia is about as rare as golden rocking horse sh!t, and no local brake places were able to come up with a solution.

When I got home and got the rest of the bits cleaned up, I noticed really heavy scoring in my nice new axle shaft. inside the larger (outer) bearing there is also really bad scoring, yet this was a brand new bearing onto a brand new axle. Fitted up with a liberal smearing of grease to help the fit, but it's really quite bad.

So here's a couple of interesting questions?

1. Bob's axles are beautifully finished to a very exacting tollerance. The bearing was a new USA manufactured bearing yet somehow I ended up with serious scroing on the axle shaft. How can this be?

2. Why couldn't I get the tension wrench to 'click' at 350lbs like I could on the other side?

3. When first fitted, the rotor turned fine, but when the tesnion of 300 lbs went onto the hub nut I was not able to rotate the disc anymore. I don't get this as you have the axle, then the spacer cup, then the bearing, spacer tube, inner bearing, flange, washer and nut. There isn't anything else and both sides are the same, yet one has 350ft/lbs on it and rotates freely and the other bound up!

Now, for standard rear solid rotors, who is best to get these from?

I see Wilkinsons lists three rotors. One solid, one vented, and one vented GT5.

Will both of the first two fit my car, or do I stick with the solid that it had?

All things- even precision bearings & axles- have tolerances. And with press fits, the assembly requirements are in the ten-thousandths of an inch range. A proper pressfit on axles is 0.0005" to 0.0008" larger than the bearings for that assembly. One simply cannot check this with a std calipers. I use extreme-pressure rear end lube or Lubriplate moly-grease on axles when pressing, and for really tight fits, its well to freeze the axle and heat the bearing to about 150F degrees before pressing.

The only thing I can think of for your lock-up problem is, the extreme press pressure bent the outer steel bearing retainer, and there's not much clearance between that retainer and the wheel-stud heads. Likely, the torque wrench was still trying to pull the nut down tight so it didn't 'click'; 300 ft-lbs is not enough torque. Around 450 ft-lbs is more realistic and is why one uses new nuts if they are the sliced ones that twist when tightened. Filing the scratches flat (but not out completely) on the scored new axle will work fine, as will selectively fitting a new bearing to the 'tight' axle. You may find a new bearing that FALLS ON- that obviously is on the other end of the tolerance scale! One thing with a press: do NOT use simple stand-offs on the brake rotor to back up the pressing: you will shatter the disc- as your mechanic found. I use a huge steel pipe cap 6" thick with a hole bored thru that just clears the axle flange and contacts the rotor on its curved edge, not on the braking surface. Others use wood or plastic stand-offs made the same way. I know of several owners- including vendors- that have broken cat iron brake rotors trying to disassemble.

Finally, drive or press out all 5 wheel studs before pressing an axle in or out; this removes about half the pressure required to assemble/disassemble a properly sized Pantera rear suspension.

Vented rotors will stabilize on a hard-driven Pantera about 200F degrees lower than solid rotors, so if your driving will be at Bathurst or other such, you'll need vented rotors on both ends and Porterfield R-4S brake pads, to keep from brake fade- especially with the deeply-embedded brakes on a GT5-S! On streets & highways with only occasional stops, either rotor will work fine. Hang in there- this WILL go together.

The only thing I can think of for your lock-up problem is, the extreme press pressure bent the outer steel bearing retainer, and there's not much clearance between that retainer and the wheel-stud heads. Likely, the torque wrench was still trying to pull the nut down tight so it didn't 'click'; 300 ft-lbs is not enough torque. Around 450 ft-lbs is more realistic and is why one uses new nuts if they are the sliced ones that twist when tightened. Filing the scratches flat (but not out completely) on the scored new axle will work fine, as will selectively fitting a new bearing to the 'tight' axle. You may find a new bearing that FALLS ON- that obviously is on the other end of the tolerance scale! One thing with a press: do NOT use simple stand-offs on the brake rotor to back up the pressing: you will shatter the disc- as your mechanic found. I use a huge steel pipe cap 6" thick with a hole bored thru that just clears the axle flange and contacts the rotor on its curved edge, not on the braking surface. Others use wood or plastic stand-offs made the same way. I know of several owners- including vendors- that have broken cat iron brake rotors trying to disassemble.

Finally, drive or press out all 5 wheel studs before pressing an axle in or out; this removes about half the pressure required to assemble/disassemble a properly sized Pantera rear suspension.

Vented rotors will stabilize on a hard-driven Pantera about 200F degrees lower than solid rotors, so if your driving will be at Bathurst or other such, you'll need vented rotors on both ends and Porterfield R-4S brake pads, to keep from brake fade- especially with the deeply-embedded brakes on a GT5-S! On streets & highways with only occasional stops, either rotor will work fine. Hang in there- this WILL go together.

OzGT5 (Guest)

Thanks Jack.

I actually tried to do it right. I found a length of 195mm ID steel pipe and parted a length off so that it would support the entire way around the rotor, but I was right on the edge of the braking face, so the 'top hat' section was captive inside my pipe.

Hard to say what they did, but maybe it was crooked or something? Now I just need to find new rotors and move on.

After hours of searching last night it seems that only Wilkinson advertise a 'standard' rotor for my 74 L model. They are not expensive, but I know the shipping will be due to the weight.

Surely somebody has come up with a modification for a slip on rotor for these cars using a common and available rotor?

I thought about it during the night. Purchase a new set of wheel studs with the knurling right at the head like Toyota/Ford use. I'm using Bob's axles so the head of the axle is really thick and would support the studs beautifully. Assemble everything as normal but without the rotor.

Then find a rotor with a deeper top hat section that slips over from the outside and locates on the new studs and also the deep centre flange of Bobs axles.

I had a rear rotor in the shed from an early 90's Lexus SC400. I laid my back wheel down on it's face and then sat the rotor in there and aligned the stud holes by eye. Then I grabbed my new axles and sat it in there. The centre bore of the Toyota rotor was a perfect fit on bobs axle. There was still 10mm of the locating flange sticking through the rotor and this fitted perfectly into my wheel. SO you only have 10mm to locate into the wheel, but many cars only have 6mm anyway.

As the Toyota / Lexus has a small handbrake drum inside the rear rotor, the main body of the axle fitted perfectly in there.

The standard top hat on the solid rotor appears to be 42mm high from the rotor face. Bob's axle heads are 14mm thick. Toyota rotor face is 5.5mm thick.

All one would need to do is some mathmatics to

establish the top hat height required to put the braking face of the rotor in the middle of the caliper and it shouldn't be too tricky to do that.

I just did a quick drawing. Considering rotor is 18mm thick (>???<) and original top hat is 42mm high from the rotor braking face then its 64mm centre of caliper to mounting face for the wheel.

If I used a slip on rotor from any 114.3 PCD 5 stud configuration Japanese or Ford car with an internal rear handbrake (so it will take the axle) then I would need to find a rotor with a 55mm top hat height to maintain the same 64mm to the centre of the caliper from the wheel mounting face, which would now be on the rotor, not the axle.

This would make it so much easier to change rear rotors, never having to go through this hell of dissasembly and trying to find tools to get 400lbs out of that split nut.

I need some clarification on what thickness the standard rotor is as mine are 18mm and used.

What's your thoughts Jack?

I actually tried to do it right. I found a length of 195mm ID steel pipe and parted a length off so that it would support the entire way around the rotor, but I was right on the edge of the braking face, so the 'top hat' section was captive inside my pipe.

Hard to say what they did, but maybe it was crooked or something? Now I just need to find new rotors and move on.

After hours of searching last night it seems that only Wilkinson advertise a 'standard' rotor for my 74 L model. They are not expensive, but I know the shipping will be due to the weight.

Surely somebody has come up with a modification for a slip on rotor for these cars using a common and available rotor?

I thought about it during the night. Purchase a new set of wheel studs with the knurling right at the head like Toyota/Ford use. I'm using Bob's axles so the head of the axle is really thick and would support the studs beautifully. Assemble everything as normal but without the rotor.

Then find a rotor with a deeper top hat section that slips over from the outside and locates on the new studs and also the deep centre flange of Bobs axles.

I had a rear rotor in the shed from an early 90's Lexus SC400. I laid my back wheel down on it's face and then sat the rotor in there and aligned the stud holes by eye. Then I grabbed my new axles and sat it in there. The centre bore of the Toyota rotor was a perfect fit on bobs axle. There was still 10mm of the locating flange sticking through the rotor and this fitted perfectly into my wheel. SO you only have 10mm to locate into the wheel, but many cars only have 6mm anyway.

As the Toyota / Lexus has a small handbrake drum inside the rear rotor, the main body of the axle fitted perfectly in there.

The standard top hat on the solid rotor appears to be 42mm high from the rotor face. Bob's axle heads are 14mm thick. Toyota rotor face is 5.5mm thick.

All one would need to do is some mathmatics to

establish the top hat height required to put the braking face of the rotor in the middle of the caliper and it shouldn't be too tricky to do that.

I just did a quick drawing. Considering rotor is 18mm thick (>???<) and original top hat is 42mm high from the rotor braking face then its 64mm centre of caliper to mounting face for the wheel.

If I used a slip on rotor from any 114.3 PCD 5 stud configuration Japanese or Ford car with an internal rear handbrake (so it will take the axle) then I would need to find a rotor with a 55mm top hat height to maintain the same 64mm to the centre of the caliper from the wheel mounting face, which would now be on the rotor, not the axle.

This would make it so much easier to change rear rotors, never having to go through this hell of dissasembly and trying to find tools to get 400lbs out of that split nut.

I need some clarification on what thickness the standard rotor is as mine are 18mm and used.

What's your thoughts Jack?

Attachments

OzGT5 (Guest)

Has anyone fitted the double row inner wheel bearing conversion?

I purchased these bearings locally and as the new beariing was 12.2mm wider than the original I had a machine shop turn down my spacer tube by 12.2mm to compensate for this.

Both tubes were done and both were the same when completed, but given my problems yesterday, I'd really like to know what the total length of the spacer tube is supposed to be, just in case my RHS has been squashed a bit and this may have contributed to yesterdays issues.

Even if you could tell me what a new standard sparer tube should be, I can just subtract 12.2mm from that and then check mine.

I purchased these bearings locally and as the new beariing was 12.2mm wider than the original I had a machine shop turn down my spacer tube by 12.2mm to compensate for this.

Both tubes were done and both were the same when completed, but given my problems yesterday, I'd really like to know what the total length of the spacer tube is supposed to be, just in case my RHS has been squashed a bit and this may have contributed to yesterdays issues.

Even if you could tell me what a new standard sparer tube should be, I can just subtract 12.2mm from that and then check mine.

OzGT5 (Guest)

Anyone know the correct length of the factory spacer tube?

OzGT5 (Guest)

Luck has smiled upon me.

Imagine finding a 72 model solid rear rotor in Perth, Western Australia that has a fresh grind and is 18.35mm? Freaky, but great!

And I picked up a stock spacer tube also.

Now if Jack or Mike or Larry or anybody can tell me the exact length of a stock spacer I would be most appreciative.

I assembled the drivers side tonight ready for the wheel to go on, and also fitted a set of baby tornado mirrors today. They appear to work really well and look the part.

Imagine finding a 72 model solid rear rotor in Perth, Western Australia that has a fresh grind and is 18.35mm? Freaky, but great!

And I picked up a stock spacer tube also.

Now if Jack or Mike or Larry or anybody can tell me the exact length of a stock spacer I would be most appreciative.

I assembled the drivers side tonight ready for the wheel to go on, and also fitted a set of baby tornado mirrors today. They appear to work really well and look the part.

OzGT5 (Guest)

Jack, I had a good look at the new axles and the sizing is a bit off.

Just below the splines and basically where the inner bearing sits, the axle measure 40.04mm. Then it goes to 40.02mm but right at the outer end of the axle, basically the last 7mm it goes to 40.06mm

That means that my bearing was pressing over 16thou then to 8 thou and then the shoulder of the bearing was pressing on to 24thou as I did the tension up on the nut.

Just too bloody tight.

So it goes to show. I spent the big bucks on what is probably the best product out there with Bob's axles, but even then, they need to be checked and adjusted a little.

I threw it on the lathe and using emery strips I linished off the high spots to give me 40.02mm all the way. So I have a press fit of 0.00078 thou, just under your guidelines.

The replacement rotor will come today so I'll report in on how it all goes together.

Still waiting for a check length on the spacer tube, seems no one has one laying around or that measurement onfile anywhere.

Just below the splines and basically where the inner bearing sits, the axle measure 40.04mm. Then it goes to 40.02mm but right at the outer end of the axle, basically the last 7mm it goes to 40.06mm

That means that my bearing was pressing over 16thou then to 8 thou and then the shoulder of the bearing was pressing on to 24thou as I did the tension up on the nut.

Just too bloody tight.

So it goes to show. I spent the big bucks on what is probably the best product out there with Bob's axles, but even then, they need to be checked and adjusted a little.

I threw it on the lathe and using emery strips I linished off the high spots to give me 40.02mm all the way. So I have a press fit of 0.00078 thou, just under your guidelines.

The replacement rotor will come today so I'll report in on how it all goes together.

Still waiting for a check length on the spacer tube, seems no one has one laying around or that measurement onfile anywhere.

Robert,

Email Bob and see if he will measure one for you.

John

Email Bob and see if he will measure one for you.

John

I'm glad you found a stock rotor, Robert. I don't check e-mails daily so I'm a bit late here.

1)-on rotor variations: Dennis Quella in Colorado Springs, CO sells ventillated rotors with an aluminum hat-section that fits over the axle flange front or rear. It obviously spaces the wheel and tire outboard by 3/8" or so. I run '69-76 Porsche 911 ventillated rear rotors with a home-made 1" thick aluminum hat section that fits behind the axle flange as-stock, but is 40% lighter. The vented 911 rear rotor has identical dimensions as stock. Some of the Swedish members did much the same using vented Volvo rotors and home-made spacers. Larry Stock of PPC-Carson City NV sells a Sierra brake conversion for front or rear that uses Porsche 911 rear rotors.

2)- due to the fact that the front bearing is captured between a counterbored step and a steel bolt-on retainer, the inner bearing position floats. So there is quite a tolerance for the inner tube spacer length: the inner bearing can move in or out as required. The only limiting factor is if the spacer gets so short from wear or constant 'squaring-up' with a lathe, that the inner companion-flange adapter for the u-joint bottoms out in the axle splines before you get enough torque on the nut to hold the assembly. Sorry- I've never calculated what that dimension might be.

As long as you're using std bearings, a near- stock spacer length should be just fine. The spacer ends need not be dressed perfectly flat; a few bumps etc won't hurt. On GTS or GR-3 club-racers that ran the optional 10" x 15" Campagnolo wheels and rather wide, sticky tires, DeTomaso used a double-row ball bearing at the inner position for better axle support. The only mod required was to shorten the spacer by the amount extra in the double row bearing. All else stayed the same.

Finally, once you get all this together again, be aware that all 16 bolts holding the halfshafts to the u-joint companion flanges must be tight. If one bolt or nut is even slightly loose, the assembly may yield a 'funny', untraceable vibration under heavy acceleration. If you feel such a thing, recheck those bolts & nuts first.

1)-on rotor variations: Dennis Quella in Colorado Springs, CO sells ventillated rotors with an aluminum hat-section that fits over the axle flange front or rear. It obviously spaces the wheel and tire outboard by 3/8" or so. I run '69-76 Porsche 911 ventillated rear rotors with a home-made 1" thick aluminum hat section that fits behind the axle flange as-stock, but is 40% lighter. The vented 911 rear rotor has identical dimensions as stock. Some of the Swedish members did much the same using vented Volvo rotors and home-made spacers. Larry Stock of PPC-Carson City NV sells a Sierra brake conversion for front or rear that uses Porsche 911 rear rotors.

2)- due to the fact that the front bearing is captured between a counterbored step and a steel bolt-on retainer, the inner bearing position floats. So there is quite a tolerance for the inner tube spacer length: the inner bearing can move in or out as required. The only limiting factor is if the spacer gets so short from wear or constant 'squaring-up' with a lathe, that the inner companion-flange adapter for the u-joint bottoms out in the axle splines before you get enough torque on the nut to hold the assembly. Sorry- I've never calculated what that dimension might be.

As long as you're using std bearings, a near- stock spacer length should be just fine. The spacer ends need not be dressed perfectly flat; a few bumps etc won't hurt. On GTS or GR-3 club-racers that ran the optional 10" x 15" Campagnolo wheels and rather wide, sticky tires, DeTomaso used a double-row ball bearing at the inner position for better axle support. The only mod required was to shorten the spacer by the amount extra in the double row bearing. All else stayed the same.

Finally, once you get all this together again, be aware that all 16 bolts holding the halfshafts to the u-joint companion flanges must be tight. If one bolt or nut is even slightly loose, the assembly may yield a 'funny', untraceable vibration under heavy acceleration. If you feel such a thing, recheck those bolts & nuts first.

OzGT5 (Guest)

Thanks Jack.

Interesting info that DeTomaso themselves used the double row inner. I wasn't aware of that. Thought it was a recent USA invention. So that's good for me as I have that double bearing and have which is 12.2mm wider than the stock single race bearing. Hence I machined down the spacers by 12.2mm to 45.7mm total height.

The rotor hasn't arrived yet, Australia is a big country for a truck and apparently we don't have airplanes!

I wasn't happy with the exhaust flange on the RHS headers so today I removed them, welded the flange and have just refitted them. Actually not a bad job, easier than many headers I've had to deal with over the years.

I called Kirk this morning and he will have my small bumpers ready by end of next week so it should fall into place that they arrive as the car gets back on the road.

Interesting info that DeTomaso themselves used the double row inner. I wasn't aware of that. Thought it was a recent USA invention. So that's good for me as I have that double bearing and have which is 12.2mm wider than the stock single race bearing. Hence I machined down the spacers by 12.2mm to 45.7mm total height.

The rotor hasn't arrived yet, Australia is a big country for a truck and apparently we don't have airplanes!

I wasn't happy with the exhaust flange on the RHS headers so today I removed them, welded the flange and have just refitted them. Actually not a bad job, easier than many headers I've had to deal with over the years.

I called Kirk this morning and he will have my small bumpers ready by end of next week so it should fall into place that they arrive as the car gets back on the road.

OzGT5 (Guest)

Removed the clutch master and slave too. Master wasn't fun to get out. Trying to get that pin out above the throttle pedal was a nightmare.

Both are really tired, rusty and badly pitted. They have been sent off to local brake and clutch specialist for a sleeve and rebuild.

Mechanically and structurally, she's going to be good. Hope all this effort is worth it.

Both are really tired, rusty and badly pitted. They have been sent off to local brake and clutch specialist for a sleeve and rebuild.

Mechanically and structurally, she's going to be good. Hope all this effort is worth it.

OzGT5 (Guest)

Okay, the disc from Perth arrived today and I had everything ready to go.

First stage was to press the outer bearing into the hub and then fit the bearing retainer and the four screws. I used a Loctite stud retainer on these screw and also an impact driver to tighten them securely without damage.

Then a light lubricant to the axle and I offered up the axle mounted to the rotor with the cupped washer in place on the axle. This went into the press and all went together well.

Then over to the bench and I have the rotor face down with the assembly resting on the tips of the studs and I test rotate the hub. Hmmm.....something is binding.

After a while I figure out that the top of the studs are touching on the bearing retainer plate or the four screw. Not good.

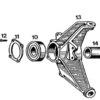

So back to the press and remove the axle again, and sure enough there are two studs touching on the bearing retainer ring. Number 11 in this picture.

I'm thinking that these tollerances are just way to close if a coat of thick paint can make the studs rub on this retainer and I start to think that maybe something is missing here?

Back to the parts book and an exploded diagram, and sure enough, I appear to be missing a component.

Now everything that came out has gone back in, no leftovers, so maybe whoever did the last set of bearings or rotors may have left something out.

Part 8 on the drawing below is the specialy cupped washer that goes over the step at the base of the axle. I have this component and it's quite clear where it goes.

Part 9 on the drawing I do not have!

The parts manual calls it up as an outer dust shield, but I have no details about it and certainly don't have them in either side of the car.

Can somone help with this. Please explain what this is, the purpose and I need to know what it looks like as I'm going to need to make this component now before I can put it all together.

And.......bugger it. I'll have to pull the LHS apart agian and fit this in, even though the LHS tensioned down fine and does not touch anything.

First stage was to press the outer bearing into the hub and then fit the bearing retainer and the four screws. I used a Loctite stud retainer on these screw and also an impact driver to tighten them securely without damage.

Then a light lubricant to the axle and I offered up the axle mounted to the rotor with the cupped washer in place on the axle. This went into the press and all went together well.

Then over to the bench and I have the rotor face down with the assembly resting on the tips of the studs and I test rotate the hub. Hmmm.....something is binding.

After a while I figure out that the top of the studs are touching on the bearing retainer plate or the four screw. Not good.

So back to the press and remove the axle again, and sure enough there are two studs touching on the bearing retainer ring. Number 11 in this picture.

I'm thinking that these tollerances are just way to close if a coat of thick paint can make the studs rub on this retainer and I start to think that maybe something is missing here?

Back to the parts book and an exploded diagram, and sure enough, I appear to be missing a component.

Now everything that came out has gone back in, no leftovers, so maybe whoever did the last set of bearings or rotors may have left something out.

Part 8 on the drawing below is the specialy cupped washer that goes over the step at the base of the axle. I have this component and it's quite clear where it goes.

Part 9 on the drawing I do not have!

The parts manual calls it up as an outer dust shield, but I have no details about it and certainly don't have them in either side of the car.

Can somone help with this. Please explain what this is, the purpose and I need to know what it looks like as I'm going to need to make this component now before I can put it all together.

And.......bugger it. I'll have to pull the LHS apart agian and fit this in, even though the LHS tensioned down fine and does not touch anything.

Attachments

There are a number of images of the cupped washer/spacer on this page http://www.panteraplace.com/page87.htm Keep in mind that I’m running a Timkin tapered roller setup and there is an extra spacer to the outside of the bearing. Your spacer must have stuck to your old axels.

Mike

Mike

OzGT5 (Guest)

No Mike, it's only this component called a 'dust seal' and is number 9 in the picture above that is missing.

I called Tony in Perth and his car is exactly the same as mine, and is missing the dust seal part number 9.

The axle spacer is there, no worries.

I called Tony in Perth and his car is exactly the same as mine, and is missing the dust seal part number 9.

The axle spacer is there, no worries.

OzGT5 (Guest)

Here's some images to explain things.

First, my axle spacer, which is number 8 in the image above and goes onto the axle first before pressing through the outer bearing.

First, my axle spacer, which is number 8 in the image above and goes onto the axle first before pressing through the outer bearing.

Attachments

OzGT5 (Guest)

Here's a picture after I pressed everything apart again. Note the black powder. That's black paint from the bearing retainer rubbing on the stud head, and you can see a curved mary on the stud head from touching the screws that hold the bearing retainer.

Attachments

OzGT5 (Guest)

and here's the bearing retainer ring. You can see the areas that have been in contact with the stud heads.

Attachments

quote:Originally posted by OzGT5:

No Mike, it's only this component called a 'dust seal' and is number 9 in the picture above that is missing.

I called Tony in Perth and his car is exactly the same as mine, and is missing the dust seal part number 9.

The axle spacer is there, no worries.

Well, I messed that up!! My car did not have that part 9 either. In that case there can only be a few things causing the problem:

1. The step on the axel where the cupped washer/spacer fits is not the same as the stock axel. I can’t tell from your picture, but note on my axel images that there is a fairly thick space/step between the rotor mating surface and the area that the cupped washer contacts. The rotor hub should be the same thickness, right.

2. The bearing hub is not the same width at stock. Note that the hub/inner race sticks out some in my images.

3. The wheel stud flange is thinker than stock but I think I recall that you reused your studs.

After following your thread all these months I’m feeling very fortunate that the projects on my car have gone so well.

Mike

OzGT5 (Guest)

Thanks Mike.

The flange that part 8 sits on is 0.35mm higher than the original stock axles. This would have the effect of sitting the cup washer higher, therefore relieving the issue rather than compounding it.

Yes, you may be right and the actual head of the axle where the wheel sits may be thicker by 0.75mm - 1.0mm. This would force the rotor further inboard and may cause the contact.

Obviously last week when I fitted the first hub together, applying the 350 ft/lbs of pressure must have forced the stud heads firmly against the countersunk screws on the bearing retainer and caused the total lockup.

12.11 am in Oz so I'll get up and back to it in a few hours. It's Saturday here so I have most of the day to sort out the issue.

The flange that part 8 sits on is 0.35mm higher than the original stock axles. This would have the effect of sitting the cup washer higher, therefore relieving the issue rather than compounding it.

Yes, you may be right and the actual head of the axle where the wheel sits may be thicker by 0.75mm - 1.0mm. This would force the rotor further inboard and may cause the contact.

Obviously last week when I fitted the first hub together, applying the 350 ft/lbs of pressure must have forced the stud heads firmly against the countersunk screws on the bearing retainer and caused the total lockup.

12.11 am in Oz so I'll get up and back to it in a few hours. It's Saturday here so I have most of the day to sort out the issue.

OzGT5 (Guest)

The factory clearance from head of wheel stud to those countersunk head screws and the bearing retainer must be miniscule?

You would like to see 3 or 4mm here to allow some clearances but this seems not to be the case.

I thought the caliper mounting tabs were close to the rotor surface, but the stud head clearance is crazy.

You would like to see 3 or 4mm here to allow some clearances but this seems not to be the case.

I thought the caliper mounting tabs were close to the rotor surface, but the stud head clearance is crazy.

OzGT5 (Guest)

quote:After following your thread all these months I’m feeling very fortunate that the projects on my car have gone so well.

Mike

It's certainly been an interesting few months Mike. It's made more difficult by being on the other side of the World where there are only a (small) handful of these cars and vitually no local knowledge to draw from.

Having Paul locally and Tony in Perth has been great, but without you guys on this forum I would be floundering with little chance of rescue.

You are all great and I appreciate your help.

In another few weeks it should all be worth it, and then I'll start the small jobs like the steering rack mods, electricals, switch gear, console treatment etc.

Will it ever end?