The Campy wheels on my Euro Pantera seemed to have about 10 or 15 coats of rattle can paint on them. I took the plunge and decided to refinish them. I had a service strip the paint and lightly blast the wheels. The photo below is my painter applying primer to the bare wheels. He liked the rack that I made for this effort because he can rotate the wheels while shooing the paint. His next step is to sand the primer and then apply a silver base coat followed by clear coat.

Replies sorted oldest to newest

What kind of primer did he use?

I seem to recall that a special (chromate-based?) primer is required for bare magnesium??

Larry

You need to use zinc chromate primer. Campagnolo used green zinc chromate primer. You can buy it at most aircraft shops such as www.aircraftspruce.com .

I have read conflicting articles about refinishing magnesium. A Ferrari restorer said to not to use chromate primer and instead to use epoxy primer. While browsing I could not find a single epoxy primer that is intended to go onto magnesium. They are all intended for steel and aluminum.

My painter is using all Sherwin Williams products that are designed as a system. I asked if he could use epoxy primer and he said that it is not part of his paint system and would not be able get support if something goes wrong. Hence we are using Sherwin Williams DTM (direct to metal) primer. Time will tell if this primer gets the job done.

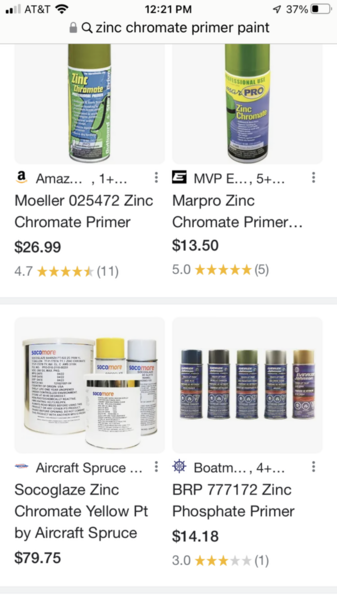

I could not find a zinc chromate primer at AircraftSpruce. I did see a zinc phosphate primer. Again, it says it is for steel and aluminum:

Overview

| Maximum adhesion to bare aluminum and steel Tempo's Zinc Phosphate Primers are recommended for priming bare metal. These primers provide maximum bonding to bare aluminum and steel. Tempo's Primers have been the workhorse in the aviation industry for many years. |

Hmmmmm….

I think I would most definitely have erred on the side of caution and followed decades of traditional magnesium painting processes, instead of trailblazing a new approach because of your painter’s product preferences.

I am sure the wheels will look just fine upon finishing with the non-traditional painting process.

Obviously, the question of whether your painter’s approach will provide ….long-term…. paint adhesion is one that will not be immediately revealed.

Larry

Thanks for sharing, Steve. Please post pictures of the final results. It will be nice to see them in person at an OC Pantera event.

Larry, I agree. However, those special purpose primers are not readily available. And if you can find it then there are possible compatibility issues with the base and clear coat paint.

This car is almost never exposed to water. It rarely rains in my area and when it does I simply don't take it out. There is a good chance this paint will stay put for a long time. As a courtesy to others I will report back if this paint fails.

Attachments

If I were to drive this Pantera down into the water at boat ramps in Long Beach harbor and let it soak for a while then I definitely should have used it. Still no mention of use with magnesium.

Product Description

Moeller Part #025472

Zinc Primer

Zinc Chromate: For aluminum surfaces above or below the waterline. This powerful primer etches into the aluminum, forming a strong surface/primer union that is resistant to corrosion. For professional use only.

Zinc Phosphate/Cold Galvanizing: For steel and iron surfaces, especially welded joints above and below the waterline. This corrosive barrier contains 95% of zinc, for maximum resistance against solvents & abrasions.

Steve,

One final question.

you have stated you could find no zinc chromate primer that indicated it was appropriate for use on bare magnesium.

So, was there anything in the literature for the Sherwin-Williams primer your painter used that indicated ….it…. was appropriate for use on bare magnesium?

Larry

Hi Larry,

I looked at Sherwin Williams' website and nothing about magnesium was mentioned as well. They only say that it "promotes excellent adhesion" and that it is direct to metal. I think there is a very limited market for bare magnesium specific primers and the manufactures do not put effort into such products. As I mentioned above, my painter was very comfortable with applying this primer, base, and clear coat to my bare wheels. If the paint job fails there is a possibility of getting Sherwin Williams involved. When wet sanding the primer today there was only indication of correct adhesion. My plan is to keep this car long term. If issues arise with this paint job I will make this forum aware of the problem.

I have to let paint cure for a while and plan to mount the tires next week. I will post a picture of the wheels on the car at that time.

Thank you, Steve

They look good!

Im interested in how long your paint holds up. Let us know. I had my wheels powder coated locally ( st louis ) .They lasted 1 year before peeling. They warranty them. Now 1 year later they are failing again. Im always nervous during the dismount and mount tires. Between the wheels and radiator I cant get a break....

Powder coating 50 year old magnesium wheels is a problem-filled project.

50 years of exposure will most likely have contaminants trapped within the pores of the magnesium. Knowing this many shops will refuse to powder coat such wheels because of the outgassing and the damage it can cause to the paint surface.

depending on the condition of the wheels they need to have contaminants baked out of them by at least one heat cycle, if not more,

Larry

As for durability of “wet” paint, there are still hundreds, if not thousands, of factory-painted Pantera wheels that still have quite presentable finishes.

The factory used a zinc chromate primer prior to their top color coat. Obviously that industry-standard approach has demonstrated its worthiness.

hard to beat 50 years of durability.

not many of us will still be alive to evaluate the long-term durability of the non-factory methods.

Larry

I powder coated the single slot Campy's on my Pushbutton with the setup in my garage and they are still holding up nicely after nearly four years. I have never had powder coat peel and have done a lot of it. I have had other issues but never peeling. Surface preparation is critical for powder coating which usually means bead blasting.

Attachments

Attachments

Looks Good Steve. Like the Campy sticker, nice touch for original.