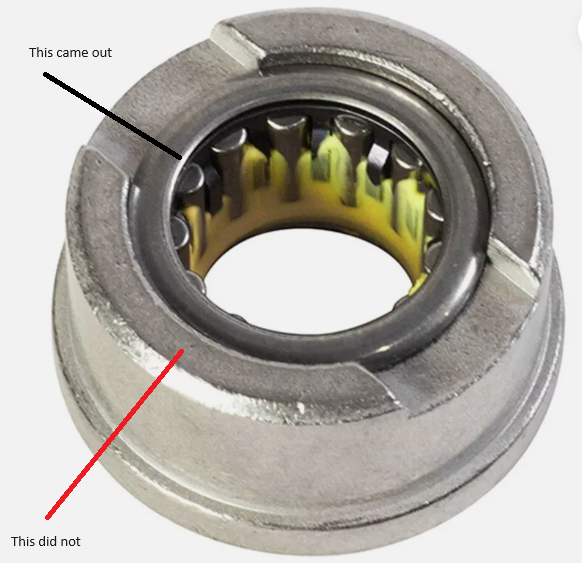

Not sure what to call it. I received the new Bronze Pilot Bearing from Marlin and am preparing to install it. I got the old pilot needle bearing out but now there is one more bushing? or something that needs to be removed. The pilot bearing removal tool could not get a grip in it to remove. Any thoughts on this? The roller bearing has an OD of ` .93". The new bronze bearing is ~1.38". The flange on the crank has a OD of `1.74" and then the new bearing will fit inside that. I can give you a drawing of what I see if that will help.

Thanks ahead for any assistance.

Ken