quote:

to serve as alignment pins

I think because the 31-A studs would need to be pretty short to prevent them contacting the rotating clutch assembly, they wouldn't be of value.

That is because the ZF input shaft would be trying to mesh with the clutch disk splines long before the 31-A studs could enter the bellhousing holes to provide alignment.

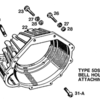

When installing the bellhousing and ZF as one unit, I have heard of using studs on the upper two bellhousing-to-engine block bolts as alignment pins.

These studs can be made from bolts long enough to allow them to engage the bellhousing holes prior to the ZF input shaft hitting the clutch disc splines. Remove studs and replace with bolts after installation.

I've found the hardest alignment issue is the clutch disk. Plastic alignment tools, or an old input shaft from another Ford tranny solve that problem. The later dash-2 ZF can use a standard Ford V-8 alignment tool (sometimes included with clutch assemblies or cheaply purchased), however the dash-1 is a different spline size.