I bought a stroker 393 without a intake and we had to take .003 of the intake flanges. Ran it up on the test stand and found a small drip of water coming out between lower corner of intake and head. Oil is clear no milkshake. Did he not use enough RTV sealant on the intake. Not running the valley pan.

Replies sorted oldest to newest

Is your motor a Cleveland or a Windsor?

Larry

It is a Cleveland engine. the drip was from the back of the engine.

A little more RTV in that area plus more care in installing the intake. They can also suck oil from the block valley into an intake port if you're careless, or use steel shim intake gaskets or the so-called 'turkey-roaster'. I personally ALWAYS use composite intake gaskets and a thick bead of silicone without the stock cork 'china-wall' end gaskets at all.

Good to hear. We will be removing the intake and using more silicone sealer in the corners. Thanks for the info. I will make sure he uses FelPro gaskets.

Good afternoon Goodwin, take the bosswrench advice. As an alternative, we don't use the front/rear cork gaskets, we throw them away. Haven't used them in years. Buy a can of 'The RightStuff' and be done with it forever. Pull the intake, clean clean clean. Remove the carburetor. Add a healthy portion of The Right Stuff front & rear, pause for a minute or so. Get a friend to help setting the (lighter more maneuverable) manifold down exactly where it will stay no wiggling around. Get it right the 1st time. It will never leak in a hundred years. Be the best 22 dollars you ever spent on the car, lol. We've never once had to repeat.

If I am missing something, I’m sure someone will point out where I am going wrong, but……

there are, of course, water passages between the cylinder heads and the engine block

But the Cleveland intake manifold is a dry manifold, meaning there are no water passages between the cylinder heads and the intake manifold. There is no water in the intake manifold.

so how in heavens name is WATER leaking out of the manifold to engine block junction at the China wall corners❓❓❓

I can think of no other source for that water than an improperly installed or improperly torqued cylinder head gasket

Larry

As for correctly and easily setting the intake manifold directly in place on your first try, you do not need to have a second pair of hands but you do need four 5/16 inch studs

install them in the four vertical manifold bolt holes to use as guides when lowering the manifold into place

install the other manifold bolts, pull the studs and install those four bolts and torque everything according to the Ford torque instructions

and yes, I strongly endorse the aerosol can of PermaTex right stuff for the China wall gasket

Larry

...Larry 'Hit the Nail Right on the Head!' Miss-Torqued Heads! And The '4 Stud Manifold Alignment', Idea, was First Invented and Suggested By ME! The Bonus is, they also keep the Gasket from Slipping Down, out of Alignment, when you Drop the Manifold Straight Down.

My Iron Heads, on Iron Block, are Installed with ARP Studs and are Torqued to 135 FT/LBS!! Think I'am Wrong...call up the ARP Technicians, Yourself! Aren't using studs?, then Look Up the Head Bolt Torque for the 'BOSS 351', Your heads on Your Block.

MJ

Marlin,

I picked up that tip from you so long ago I had totally forgotten where I got it. Hard to remember what I had for breakfast these days, or even if I had breakfast, much less where I picked up all the little tips and ideas rattling around in my old gray-haired head.

next time I share that tip, I will give you credit, that’s assuming I can remember where I got it ….. 😉

Larry

Since this is a Cleveland engine, the intake manifold does not have any water passages, which has already been stated by Larry.

The only way for water to leak from the head at the area stated is from the head gasket. This could be from not enough head bolt torque, an uneven gasket surface on the head or block (or both), a bad head gasket, or a poorly cleaned gasket surface. This assumes that there are no casting cracks.

BTW, what heads does this engine have?

John

Why haven't you pressure tested it? Simple test, simple find.

Thank you, John😉

Jack and Jack, Sharkey and Bosswrench, appear to have miss-read the original post and have addressed OIL leaking from the China wall corners.

This is understandable, as I have never heard of anything but oil leaking at the China wall…….

but the original post says the leaking fluid is WATER, not oil……

if the cylinder heads were not properly torqued, I would expect water to escape from multiple locations. Since that is not the case, it is likely a HEAD gasket issue.

pull the cylinder head closest to the leak, and find the source of the water leak. Depending on what you find, it may also be wise to pull the other cylinder head.

If all you do is reinstall the intake manifold, I guarantee you will have the oil milkshake appear in short order

Larry

https://www.youtube.com/watch?...m8JZnwt7c&t=763s

I thank everybody for their insight and will try resealing the Edelbrock Torker intake.

New gaskets (FelPro) and sealer will be used.

I won't install my engine until the slow drip is resolved. Love the Ausie in the video with his flip flops and shorts. He has some good tips and tricks in all his video's.

I personally have had issues with the Cometic head gaskets but not on the 351c. On a 427 and 347 Fords. The fact that they are $92 each doesn't make them any better.

Others have had issues with Felpro. I stay with the Felpro unless I need a thinner head gasket to maintain compression ratio.

The 427 would drip oil from the driver's side head, rear, in the corner. The 347 water from the same spot. Changed out the Cometic for Felpro and the problems were solved.

It had nothing to do with having not torqued the heads properly...not a greenhorn here. It was the composite design of the gasket itself.

Cometic refunded the money on both sets and said find another manufacturer.

The only issue with the Felpro's is they are thick and only made one way, BUT they don't leak.

(The original post says "dripping water", not oil)

Dave

Attachments

Hum. I don't personally have experience with copper head gaskets but I remember they were used on 60s era GMC blower cars.

The hardness of them matters as they seal by crush rather than anything else.

I do know that teflon coated gaskets such as the Felpro are designed with crush rings around the cylinders to hold compression but permit the head and block to expand at different rates and the head literally floats on the block.

That is more important of a concept with aluminum heads on iron blocks.

The older Victor gaskets common on Fords of the 60s were sealing differently and we often needed to scrape remnants of them off of the top of the block. The Felpro's, not so much.

Unless you have crazy cylinder pressures, I don't see the need for copper gaskets or maybe stated differently, the risk (water leaks) of using them.

You don't need more then 95 pounds of torque to seal the gaskets. The fasteners aren't doing the job, the gaskets are. The only thing head studs are treating is paranoia. At some point they are counter productive and distorting the head and block.

...Sure! Wanting A 40% Increase in Clamping Force, with the FINE Nut Threads, on a Stud, that Bottoms all the way to the Bottom Length of the Blocks' COURSE Threads, Is Paranoia in your view? When I use to use the Factory Bolts I, like you, was advised to torque the Heads to 90 FT/LBS (you stated 95)...The head gasket Blew when approaching 5700RPM. I replaced them, torqued to 95, a Gasket blew a second time*. The Factory Manuel States 'BOSS 351= 125 FT/LBS'!! My C.R. is 10.5, I then Installed the ARP Studs, as mentioned earlier, called up ARP, I think They have done a 'Little' Testing on their own, their advise...Iron Heads on Iron Block 135FT/Lbs, on the Fine Threaded Nuts?! This while the Engine is In the Car. Torquing while leaning in over the Fender! Yes, the Heads CAN be slid up and over the Studs!! Took all the strength I had to hit 135.

Engine has been running Perfect ever since! Took It to the Desert at 118F Degrees, Never got Hotter than 195F, Period!

And try using 'Head Bolts' in a Aluminum Block, and see what Happens!!

MJ

* Make No Mistake, this was all on Block and Head surfaces that were Re-Dressed for Flatness and Accuracy. And I think I know a Little Bit About a 'Torquing Sequence' and More.

I vote to nominate Marlin for a Special Achievement award as a small token of our appreciation to his outstanding and often unique brilliance!

Will someone second the motion?

Yes, I second the motion and appreciate Marlin's guidance !!!

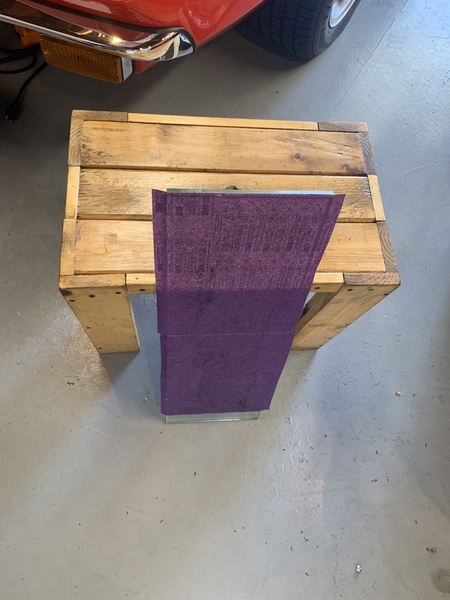

I had a problem with a water leak on the driver side cylinder head. My symptom was steam blowing out of the exhaust. The cylinder head surface was perfect and despite trying several time to replace the head gasket the problem only got worse. I finally began to focus on the block and noticed a slight rust bubble around a water passage and used my large sanding block to carefully flatten it. The sanding block is a glass shelf with sandpaper glued to it.

Attachments

What is the sign 3M?

Dave

3M is a brand name of a manufacturer…

3M typically makes adhesives and abrasives, so perhaps someone brought it up as a sealant or a gasket compound?

My guess is somebody mentioned it in one of the earlier versions of this thread (which I thought were amusing, albeit a little unnecessarily heated) or in the linked thread, above.

3M really stands for “Minnesota Mining and Manufacturing”.

EDIT: See the next post! John nailed it!

It appears in the above pic of Steve's sanding block. It is the manufacturer of the sanding sheet that is glued to his glass shelf.

John

...Doug is Right! Copper Gaskets Require a Higher Torquing to 'Crush' the Copper, Period. You can get this with a Stud kit...remember 40% Higher Clamping Force!!

As far as the Manifold End Seals, I do Not Use the 'Red' Permatex gasket maker, It is Too 'Grainy'. I use the Permatex 'Black Ultra'. The way I do it is...Squeeze a 1/4" Thick Bead of Silicone on BOTH surfaces of the Head AND Manifold, don't forget the Corners and the Major Gaskets go on First, Over the (4) Studs. Then Drop the Manifold Down while the Sealant is Pliable, Not Even Taky, this Guarantees the sealant will be Squeezed into Every Void, Plus the Sealant will also 'Stick' to the Manifold, for a more Perfect Seal!

...I see the Aussie drops the Manifold on, THEN installs 4 'Guide Bolts' Finger Loose, does a Little Shimmy on the Manifold, and then Starts Torquing 2 bolts on the one Side Only, No Torquing Sequence? Is This Serious??

Last in My view, the Red 'Mountain' of gasket maker is So THICK, he will have to really Torque on Those 'Aluminum' Manifold Bolts, to come close to compressing that mound down for the manifold to be in Alignment! And The sealant will Not be 'Adhered' to the Manifold Itself! It is Sure to Blow-Out. It's Not Very Smooth where it counts, and Grainy. FWIW

MJ

Yes. The silicone varies. The red has problems, the black is the best and less sensitive to contaminants on the sealing surfaces but I've had good luck with the simple blue as long as you wipe everything down with alchohal to get everything clean. It has to be completely dry also or you will find places when you strip it down that it didn't stick.

The black as it cures actually pulls the pieces together.

As far as the guidance studs go, I find using four is to many for me and one on each side is enough.

That isn't a new idea though. If you have worked on Ford small block 289 series engines (260-302) you will find that when using the iron intake manifolds, the factory has used studs on those four positions since the early '60s.

I'm sure that Marlin is right on that, laying down the intake, especially a heavy one like the iron intake, you get much better results if you drop it on the exact correct spot to begin with without having to wiggle it around to align the bolts.

How about just using good gaskets and installing them properly? I try my best to use a minimum of silicone. Excess squeeze out on the outside looks sloppy and I don't like to imagine the possible issues with squeeze out on the inside getting loose.

This installation has got eleven years and over ten thousand miles on it and hasn't leaked a drop.

I do re-torque/check my engine fasteners each season. Rocker cover bolts, oil pan and carb bowl screws always seem to take up a little, manifold hardware not so much after the first few times. Head bolts and internals I do not touch.

Attachments

Dave

One small addition to the foregoing from a chemist: there are several types of silicone and they don't all cure the same. I won't get into the chemistry, but common hardware-store RTV cures by exhuding acetic anhydride, which instantly reacts with atmospheric moisture to form acetic acid and gives off the familiar vinegar odor. This type should NOT be used against bare metal, as the acid will begin corroding steel and you'll get the equivalent of "rust" . If your RTV smells like vinegar, do NOT use it on windshields!

In the last half of the 20th century, professional auto glass people specified a type of RTV that cures by exhuding acet-aldehyde which is a light gas that vanishes without further reacting. It has NO odor while curing. THIS is the type of RTV commonly used on windshields at pro glass shops, and is available in tubes at windshield shops everywhere. But not at Home Depot for caulking guns! I have seen non-leaking Panteras with windshield channels so corroded by the wrong silicone, they were no longer structurally sound!

In case you are wavering on using the cork in the kits or silicone, as supplied, the cork is either too thick or too dry.

When you see how pliable and compressible the cork is supposed to be v. how you get it, you can begin to understand the issue.

You need to compress that 1/4" thick cork down to less then 1/8".

Ford ALUMINUM intake manifolds do have the WELL DESERVED reputation of being fragile on the outermost bolt flanges OFTEN breaking them completely off while attempting to tighten down those bolts while using the cork gaskets.

True the factory used them with little issue but they were very soft and pliable under those conditions.

The black rubber ones sometimes supplied in Cleveland kits are more pliable but literally need to be glued in place before you set the manifold.

By far the simplest solution is to use the proper silicone.